30/69

Description Unit of

measure

Value

Battery

Type - Li-Ion rechargeable

Battery voltage V 50,4

Battery capacity mAh 4400

Battery weight g 2800

Cutting autonomy - max 2 days

Battery charging time h 6

Electronic protections - Overexertion and

short-circuit

Time auto power-o for

inactivity min (after) 10 min

Thermal protection - Overheating

Technical data battery: In order to certify the conformity of the machine with the pro-

visions of Directive 2006/42/EC, before placing the product on

the market, the manufacturer applied the procedure described

in Art. 5. In this sense, the manufacturer has provided for: com-

pliance with the relevant safety requirements; availability of

the technical le as stipulated in Annex VI; implementation of

all the tests and inspections required by the reference stan-

dards and compliance with the essential health and safety

requirements indicated in Annex I of the Directive itself. The

construction technical le, which contains the basic project in-

formation and all the characteristics related to machine safety,

was drafted in accordance with the provisions of Annex VI-Part

A, and can be made available by the individual indicated in the

CE Declaration of Conformity for any verication carried out

by the supervisory authorities, following a justied request, as

provided for by the relevant laws in force.

Once the manufacturer has veried that the machine has been

designed and built in accordance with the provisions of Direc-

tive 2006/42/EC and that it can be used safely in the service

conditions specied in this manual, it places the Shears on the

market and accompanies the machine with:

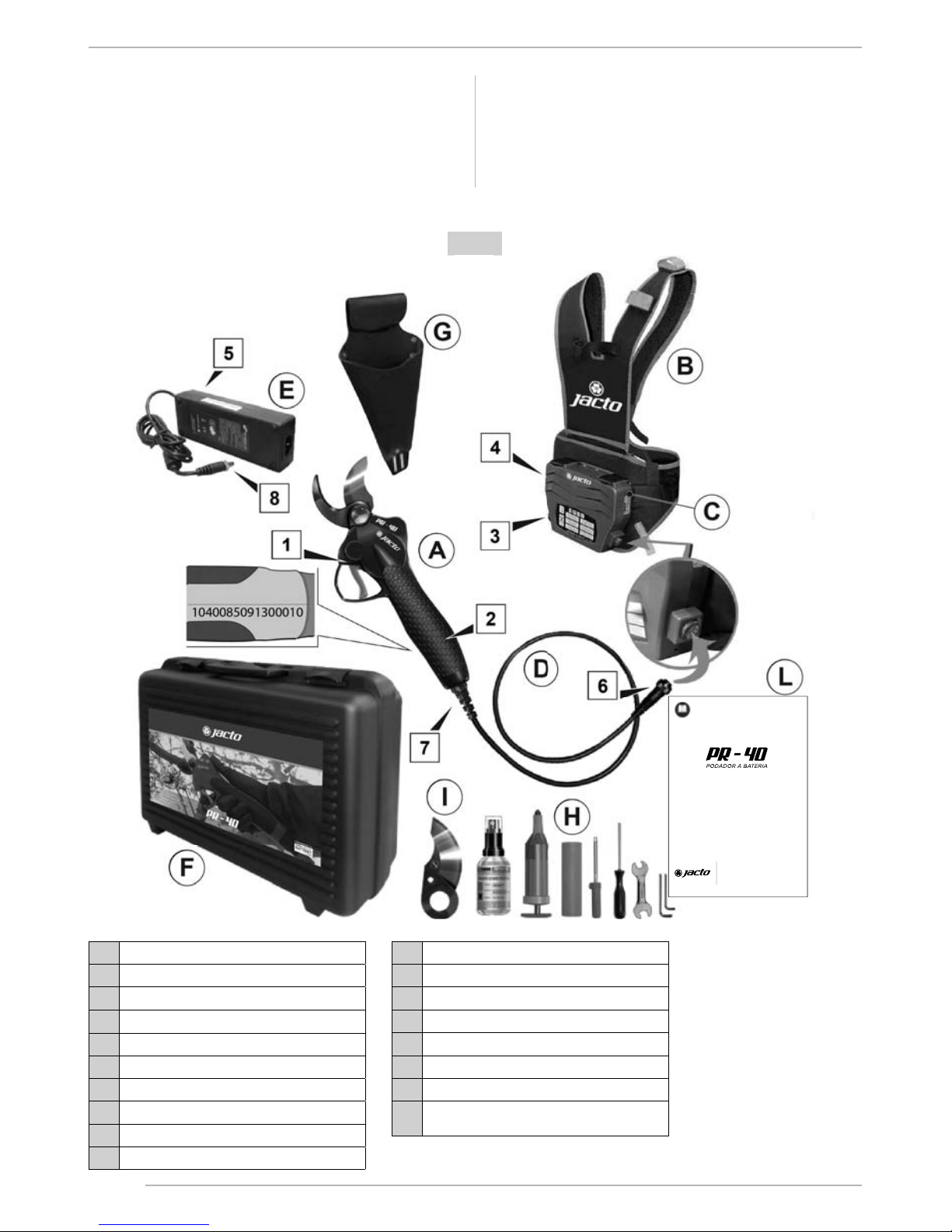

• Usage instructions booklet (User manual)

• EC Declaration of conformity

• EC Marking

In designing and manufacturing the Shears, the manufacturer

has complied with obligations resulting from applying related

European legislative provisions and precisely the following Eu-

ropean provisions:

• Directive 2006/42/CE (Machinery safety).

• Directive 2004/108/EC (Electromagnetic compatibility).

• Directive 2006/95/EC - (Low voltage).

For verication of conformity to European legislative provi-

sions indicated above, the manufacturer applied the following

European standards and technical rules:

EN 349:1993+A1:2008: MACHINERY SAFETY - Minimum dis-

tance to keep from crushing human body parts.

• EN1037:1995+A1:2008:MACHINERYSAFETY-Prevent-

ing unexpected start-up.

• ENISO3746:2010: ACOUSTICS - Determining the sound

power levels of sources using sound pressure - Control

method on a reecting surface by measuring an envel-

oping surface.

• ISO7000:2012:GRAPHICALSYMBOLFORUSEONEQUIP-

MENT - Registered symbols.

• EN ISO 11202:2010: ACOUSTICS - Noise emitted by

machinery and equipment - Determination of emission

sound pressure levels at a work station and at other

specied positions - Site control method.

• ENISO12100:2010:MACHINERYSAFETY-Basicconcepts,

general principles for design.

• EN ISO 13524:2009: Machines for road maintenance -

1.9. Sound level

The air noise level created by the Shears under operating con-

ditions was detected using a sound level meter with integrator.

The measurements were carried out in accordance with EN ISO

3746-2010. Tests performed under the conditions indicated by

the standard produced the following results:

• Equivalentweightedsoundpressureaveragelevel:LpAm

= 60,2 dB(A).

• Sound power level: LwA = 71,8 dB(A).

• Soundpressurelevelatoperator’sstation:LpA=60,6dB(A).

1.10. Vibration level

The level of vibrations transmitted to the operator’s hand-

arm system by the Shears in operating conditions has been

measured, in compliance with standard EN ISO 20643:2008/

A1:2012.

The tests have given the following results:

• No-loadoperation:weightedRMSvaluemeasuredonthe

handle of the shears: a = 0.53 m/s².

• Load operation: weighted RMS value measured on the

handle of the shears: a = 1.55 m/s².

1.11. EC marking of the shears

Directive 2006/42/EC species the minimum conditions with

which a machine can be placed on the EU market. All machines

can only be marketed and put into service if the health and

safety of persons, domestic animals or property are not aect-

ed. The Shears does not fall under one of the machine cate-

gories indicated in the list set out in Annex IV of the Directive

(particularly dangerous machinery).

heq

heq

43/69

5. Troubleshooting

In the event of malfunctioning of the Shears, look for the causes in the following way:

ACOUSTIC SIGNALS

Action Acoustic signal State of the tool

Startup Press the button (3) for 1 second

3 beeps Battery on (device still not recognised)

1 beep Battery on (device recognised)

Opening operation Cutting trigger (1) pressed for 3

seconds 1 short beep Blade opening (Shears ready for use)

Cutting cycle

Cutting trigger (1) pressed + button

(3) for 0.5 seconds with blade

closed)

1 beep Blade opening change

Close stop

Cutting trigger (1) pressed twice in

quick succession, then held down

with the blades closed

1 beep Shears in standby (blades closed position)

Warning During the work

1 beep Excessive strain (b par. 3.8)

4 beeps Alarm (c par. 3.8)

Charging * Connect to the battery charger 3 beeps Shears disabled

Auto power o - 3 beeps O

INCIDENT DIAGNOSIS

Problem Cause Possible solution **

The battery does not turn on The battery is low Re-charge

The Shears have stopped in work Overexertion (stop in cutting) (“a”,“b”, “c”

paragraph 3.8)

The Shears have an overdue is in limit to protect the

equipment. In the case of overexertion, the Shears stop

automatically. Perform less heavy-duty cutting cycles.

The Shears do not work

The Shears are not properly connected

to the battery Make sure the Shears are properly connected to the battery

The battery charge is very low Make sure the batteries are charged

The device connection cable is faulty Replace the connection cable

Hardware fault Contact the Service Centre

The Shears have little cutting power

or cut badly

The cutting blade is very worn or

notched Keep the blade sharpened at all times

The counter blade is highly worn Check and change if necessary

The Shears heat up excessively

The cutting blade is highly worn or

notched Check and change if necessary or sharpen

The counter blade is highly worn Check and change if necessary or sharpen

The battery does not last long

Kept the cutting blade is highly worn

or notched Keep the blade well sharpened at all times

The counter blade is highly worn Check and change if necessary or sharpen

The charger does not work Check the state of the charger.

*For proper safety, charge the battery only with the device disconnected.

** lf the problem is not solved, you must go to your distributor and/or nearest Authorized Technical Service.