2

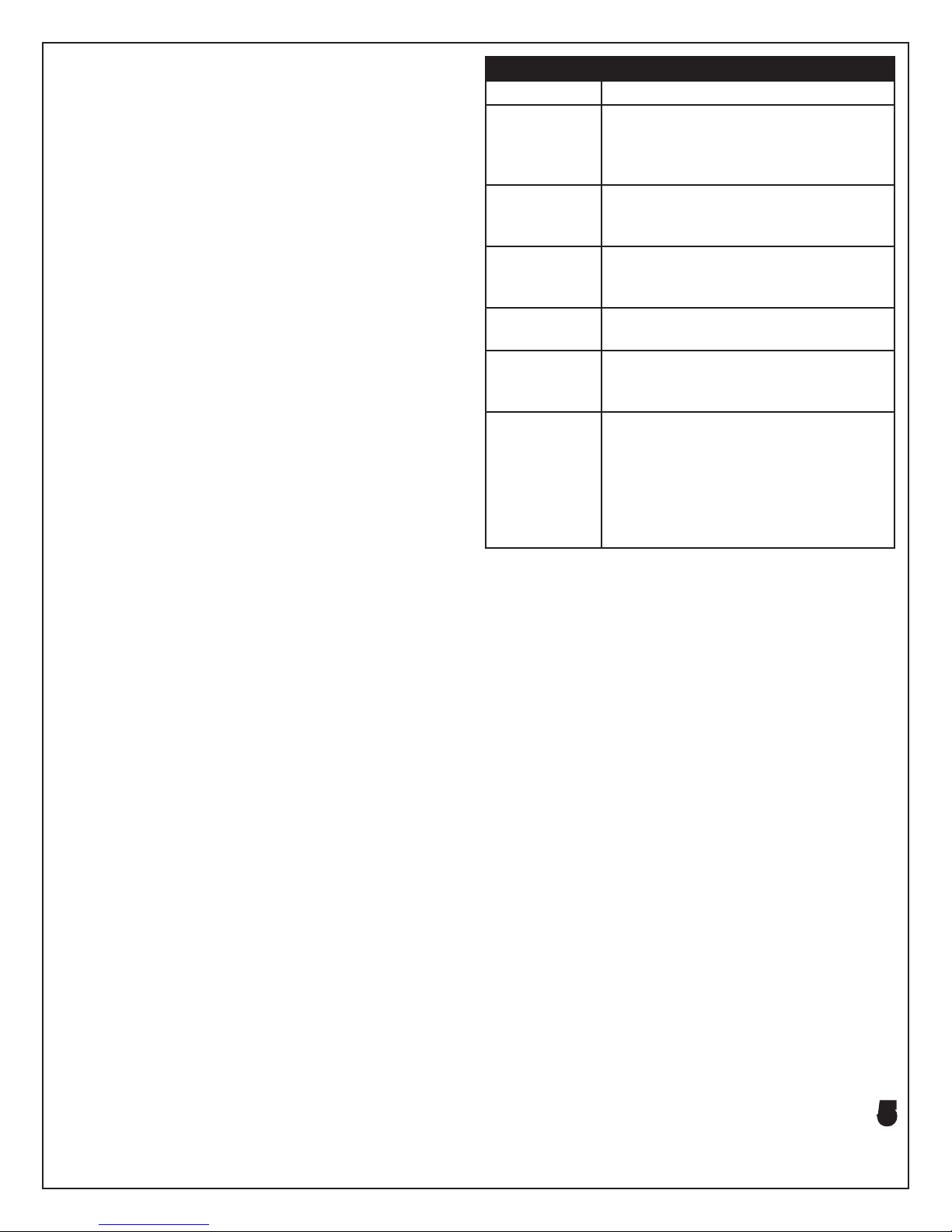

Oil cooler plumbing

The Jagg offset oil lter adapter is used to ac-

cess the oil supply for the installation of a Jagg oil

cooler. The adapter features a built-in automatic

thermostat to allow oil to by-pass the oil cooler,

simply being ltered and returned to the engine,

until the bike warms up to operating temperature.

Once the bike reaches operating temperature,

the thermostat will close the adapter’s by-pass

hole, sending hot, ltered oil to the oil cooler, and

delivering cool, clean oil to the engine.

Part 1: Installing the offset oil lter adapter

1. Remove spin-on oil lter, and clean the lter

mounting surface thoroughly.

2. If removing and upgrading a factory Har-

ley-Davidson oil cooling system, uninstall the

stock oil lter adapter by removing the anged

oil lter nipple that holds the adapter in place

using a 7/16” Allen wrench. Locate the stock-

to-Jagg oil lter nipple (shown

at right) included in the kit.

Install by inserting the or-

ange-painted end into the port

where the stock oil lter stem

was removed. Using a 7/8”

socket, tighten until the hex is

ush against the oil lter hous-

ing.

3. Disassemble the Jagg offset oil lter adapter

by removing the ve Allen head bolts from

the front face of the adapter using a 5/32”

Allen wrench. Then remove the front half of

the adapter (the portion with hose ttings

attached).

4. With the longer/offset end of the adapter at

the top, place the back half of the adapter (the

portion with the at rubber o-ring) over the

threaded oil lter stem and tighten the includ-

ed 1” lock-nut to nger-tight. The adapter’s at

sealing rubber o-ring should face in, toward

the stock oil lter housing, and be free of de-

bris. (Do not apply oil to this o-ring.)

5. Locate part 4600AR-C Jagg anti-rotation

device. Installation of this device will ensure

the Jagg 4700 offset oil lter adapter will not

rotate during oil lter removal.

6. Place the anti-rotation device

against the face of the front

half of the adapter in the ori-

entation shown below.

7. Insert the two black 10-24

Allen head bolts included

with the anti-rotation device

through the appropriate holes

on the oil lter adapt-

er.

8. Place the front half

of the adapter over

the already-installed

back half and rotate

the entire adapter

to the left until the

anti-rotation device

makes contact with

the engine case.

9. Remove the front

half of the adapter

and hold the back

half of the adapter

in its current orien-

tation. Using a 1” deep-well socket securely

tighten the 1” lock-nut so the back half of the

adapter will not rotate and the sealing o-ring

is tight against the stock lter mount. This

may require a prying force applied against the

adapter to allow tightening while retaining the

chosen orientation.

NOTE: On rubber-mounted engine models, allow

adequate clearance to ensure that the adapter

will not strike any object when the motor shakes.

Part 2: Installing the automatic fan switch

The Jagg WeatherTek fan operates via the in-

cluded automatic fan switch. The automatic

fan switch installs into the

included street-tee pipe

tting to access hot oil ow

from the oil lter adapter to

activate the fan.

Stock-to-Jagg

oil lter nipple

Automatic fan switch

Anti-rotation device tment

4600AR-C Jagg

anti-rotation device