J&E Hall HallScrew HSO 2000 Series User manual

HallScrew HSO 2000 Series

Open Drive Single Screw Compressors

HSO 2024, HSO 2028, HSO 2031 and HSO 2035

Manufactured after 06/03

Installation, Operation and

Maintenance Manual

HSO 2024 to HSO 2035 Installation, Operation and Maintenance Manual

Page 2 of 94 Publication 2-119 Issue 1.2 : 03/10

J & E Hall International

©

2010

All rights reserved. No part of this publication may be reproduced or transmitted in any form or by

any means, electronic or mechanical, including photocopying, recording or by any information

storage or retrieval system, without permission in writing from the copyright holder.

The copyright in this publication shall be and remain the sole property of J & E Hall International.

HSO 2024 to HSO 2035 Installation, Operation and Maintenance Manual

Issue 1.2 : 03/10 Publication 2-119 Page 3 of 94

Safety

In common with most other forms of mechanical and electrical

equipment, there are a number of potential hazards associated with

operating and servicing refrigeration plant.

In writing this instruction manual every emphasis has been given to safe

methods of working. These safety instructions are intended to draw

attention to the potential hazards that could be encountered during

installing, operating and maintaining the plant. At the same time, it

should be emphasised that these notes are not exhaustive, and are

principally intended to draw attention to the most important points; where

necessary, reference is made to other parts of the manual.

Please note that the installer is responsible for the correct installation of

equipment, and on completion, the owner and/or user are responsible for

safe operation and maintenance.

Personnel Permitted to Install, Commission and Maintain the Plant

It is essential that only authorised and competent personnel are allowed

to install, commission and maintain the plant. A permit to work system

should be introduced before commissioning begins, and should be

rigorously enforced thereafter.

Any person rendering assistance or under training must be supervised by

the authorised competent person who has responsibility for safety.

Personnel must be familiar with the plant’s construction, operation and

the hazards involved. All personnel should make a thorough study of

these instructions before undertaking installation, commissioning,

maintenance or repair procedures.

WARNING

A minimum of two personnel should always be present

when working on ammonia refrigeration plant.

Mechanical

Refrigeration compressors manufactured and/or supplied by J & E Hall

International must be operated within their design parameters, and

should never be used as vacuum pumps or for compressing air.

Personnel must not start the plant until they have taken steps to verify the

following:

•Guards on couplings, belt drives and fans are in place, and

other personnel are not in positions that might be hazardous

when the plant is in operation.

•The compressor discharge stop valve is fully open.

Parts of the plant, specifically the compressor, drive motor and discharge

line, are liable to be at temperatures high enough to cause a burn. A

‘cold’ burn can result from accidentally touching any part of the plant

containing oil at low temperature, or subcooled liquid refrigerant.

Personnel who stop the plant must be aware of the potential hazard if

pipeline stop valves are closed in such a manner as to trap cold liquid

refrigerant between valves. If this should accidentally occur, rising

ambient temperature will cause the liquid to expand and eventually

fracture the pipe or valves, etc.

Stop valves should be opened slowly to begin with and by a small

amount, say half a turn, before the valve is fully opened. This procedure

allows system temperatures and pressures to equalise gradually, so

reducing the risk of physical and/or thermal shock which might cause

damage.

HSO 2024 to HSO 2035 Installation, Operation and Maintenance Manual

Page 4 of 94 Publication 2-119 Issue 1.2 : 03/10

Examination of Pressure Systems

Within the United Kingdom, statutory regulations require the user to

prepare a ‘written scheme of examination’ to cover all parts of the plant

subject to pressure. It is a requirement that the scheme be introduced

before the plant is put into operation for the first time. If the plant is

modified, the written scheme of examination must be reviewed and

updated to incorporate these modifications.

Noise Hazard

The majority of noise emanating from refrigeration plant is produced by

the compressor(s), pump(s) and fan(s) and the motors which drive them.

While short term exposure to the typical average noise level which might

be encountered is unlikely to be detrimental to health, ear defenders

should be worn by those personnel who have to work near major sources

of noise. The type of ear defenders worn must not compromise the

wearing of other essential safety clothing, for example, goggles or a

respirator.

Electrical

Electrical wiring must be sized and installed to such a standard as to

meet the requirements of the national or local codes pertaining to the

area in which the installation is taking place.

The electrical power used in this equipment is at a voltage high enough to

endanger life. Before undertaking maintenance or repair procedures on

electrical equipment, personnel must isolate equipment from the electrical

supply and test to verify that isolation is complete. Precautions must be

taken to prevent circuits being inadvertently energised, for example,

withdraw the mains fuses, or, if this is not practicable, disconnect the

equipment from the supply before work commences.

If the supply cannot be disconnected or must remain connected to permit

functional testing, fault diagnosis and repair should only be undertaken by

persons who are aware of the hazard and who have taken adequate

precautions to avoid direct contact with dangerous voltages.

If electrical equipment overheats or a fault occurs, it must be

disconnected from the supply and allowed to cool. Overheating may

damage the insulation system, cables, mouldings, gaskets and seals.

The materials used in these components may contain complex organic

compounds which, when degraded by heat or electrical action, produce

chemical compounds in gaseous, liquid or solid forms. Many of these

gaseous and liquid product compounds are highly flammable and toxic.

If it is necessary to extinguish a fire in electrical equipment, follow the

advice given in the Fire Precautions Act 1971, ‘Guide to Fire Precautions

in Existing Places of Work that require a Fire Certificate’ available from

HMSO. Do not approach the equipment until the fire has been

extinguished and the equipment is cool.

HSO 2024 to HSO 2035 Installation, Operation and Maintenance Manual

Issue 1.2 : 03/10 Publication 2-119 Page 5 of 94

Lubricating Oils

Refrigeration oils are unlikely to present any significant health and safety

hazard provided they are used properly, and good standards of industrial

and personal hygiene are maintained. The following general precautions

are recommended:

•Avoid unnecessary handling of oily components. Use of a

barrier cream is recommended.

•Oils are potentially flammable and should be stored and

handled with this in mind. Rags or disposable ‘wipes’ used

for cleaning purposes should be kept well away from naked

flames and disposed of properly.

•Oil contained in the compressor lubrication system, oil

separator, oil filter etc, will remain hot enough to cause

burns for some time after the system has been shut down. If

it is necessary to open the system soon after the

compressor has stopped, to change the oil filter for example,

always allow long enough for the oil to cool down so that the

oil which is likely to escape is cool enough not to be a

danger (less than 35 °C is recommended).

Ammonia Refrigerant 717

Refrigeration systems contain liquid and vapour under pressure;

personnel should be aware of this fact at all times. Suitable precautions

must be taken to guard against the pressure hazard when opening any

part of the system.

Opening up part of the primary refrigeration circuit will necessitate the

loss of a certain amount of refrigerant to atmosphere. It is essential to

restrict the amount which escapes to a minimum by pumping over and

isolating the charge in another part of the system.

Where lubricating oil may be present, when changing the oil filter element

for example, caution must be exercised as the oil will contain a certain

amount of refrigerant which will be released when subjected to

atmospheric conditions.

Refrigerant and lubricating oil, especially liquid refrigerant at low

temperature, can cause freezing injuries similar to a burn if allowed to

come into contact with the eyes or skin. Suitable protective clothing,

gloves, goggles etc. must be worn when opening pipes or vessels which

may contain liquid.

Ammonia, refrigerant R717, is a colourless gas with a very powerful

characteristic smell which is so pungent that it is unpleasant at

concentrations too low to be considered dangerous.

Ammonia has inherent material and physiological hazards. A limited

range of ammonia/air mixtures (16 % to 27 % ammonia by volume) can

be ignited by a naked flame and an explosion may result. While

ammonia is not a cumulative poison, exposure will cause chemical burns

and can destroy body tissue. Because of ammonia’s high affinity with

water, moist areas of the skin, breathing passages and the eyes, are

areas particularly susceptible to damage.

Maintenance procedures must not be carried out unless adequate fan

assisted ventilation has been provided to avoid any risk of explosion or

physiological harm. Naked flame must not be permitted in the area.

Personnel carrying out maintenance procedures must have a respirator

of the correct type ready to wear at all times.

HSO 2024 to HSO 2035 Installation, Operation and Maintenance Manual

Page 6 of 94 Publication 2-119 Issue 1.2 : 03/10

Exits and gangways from areas where ammonia is used or stored must

be kept clear and free from obstructions to permit rapid evacuation if

there is a serious escape of ammonia. Locations from which evacuation

can only be carried out with difficulty must be designated ‘gas mask

areas’. All persons entering such areas must be thoroughly trained in the

use of respirators and carry one at the ready.

When purging ammonia or draining oil from the plant, it is essential to use

a purge apparatus as a precaution against ammonia escaping into the

plant room.

Hydrochlorofluorocarbon and Hydrofluorocarbon Refrigerants

Refrigeration systems contain liquid and vapour under pressure;

personnel should be aware of this fact at all times. Suitable precautions

must be taken to guard against the pressure hazard when opening any

part of the system.

Opening up part of the primary refrigeration circuit will necessitate the

loss of a certain amount of refrigerant to atmosphere. It is essential to

restrict the amount which escapes to a minimum by pumping over and

isolating the charge in another part of the system.

Where lubricating oil may be present, when changing the oil filter element

for example, caution must be exercised as the oil will contain a certain

amount of refrigerant which will be released when subjected to

atmospheric conditions.

Refrigerant and lubricating oil, especially liquid refrigerant at low

temperature, can cause freezing injuries similar to a burn if allowed to

come into contact with the eyes or skin. Suitable protective clothing,

gloves, goggles etc. must be worn when opening pipes or vessels which

may contain liquid.

Although not considered toxic, being heavier than air, hydrofluorocarbon

refrigerant vapour can endanger life by displacing air from cellars, ships

engine rooms, etc. If refrigerant is released accidentally, fan assisted

ventilation must be used to remove the vapour. Exposure levels in the

workplace should be kept to a practicable minimum and certainly within

the recognised threshold limit value of 1,000 parts per million (ppm)

based on an 8 hour day, 40 hour week.

While hydrofluorocarbon refrigerants are not flammable, naked flames,

for example, smoking, must be prohibited in the presence of vapour as

temperatures above 300 °C will cause it to decompose and form

phosgene, hydrogen fluoride, hydrogen chloride and other toxic

compounds. If ingested, these compounds can have very dangerous

physiological effects.

Refrigerant which is not required for immediate use must be stored in

approved containers, and the quantity held in the plant room limited.

Cylinders and drums of refrigerant must be treated with care.

HSO 2024 to HSO 2035 Installation, Operation and Maintenance Manual

Issue 1.2 : 03/10 Publication 2-119 Page 7 of 94

Contents

Safety .................................................................................................................................... 3

Personnel Permitted to Install, Commission and Maintain the Plant ...................................... 3

Mechanical .............................................................................................................................. 3

Examination of Pressure Systems .......................................................................................... 4

Noise Hazard........................................................................................................................... 4

Electrical .................................................................................................................................. 4

Lubricating Oils........................................................................................................................ 5

Ammonia Refrigerant 717 ....................................................................................................... 5

Hydrochlorofluorocarbon and Hydrofluorocarbon Refrigerants .............................................. 6

ContentsList of Figures ........................................................................................................... 7

List of Figures .......................................................................................................................... 9

List of Tables ........................................................................................................................... 9

1.

About this Publication ............................................................................................... 10

1.1.

Safety Warnings and Symbols............................................................................................10

1.2.

Units of Measurement ........................................................................................................10

1.3.

Terminology........................................................................................................................10

1.4.

Ordering Extra Copies ........................................................................................................10

2.

Misuses that Invalidate Guarantee ........................................................................... 11

2.1.

Application..........................................................................................................................11

2.2.

System Provisions ..............................................................................................................11

2.3.

Prolonged Storage..............................................................................................................12

2.4.

Commissioning Provisions .................................................................................................12

3.

General Description .................................................................................................. 13

3.1.

Main Features.....................................................................................................................13

3.2.

Construction .......................................................................................................................13

3.3.

The Compression Process .................................................................................................14

3.4.

The Compression Process .................................................................................................16

3.4.1.

Suction ...............................................................................................................................16

3.4.2.

Compression ......................................................................................................................17

3.4.3.

Discharge ...........................................................................................................................17

4.

Capacity Control and Volume Ratio.......................................................................... 18

4.1.

Slide Valve Actuation..........................................................................................................19

4.1.1.

Minimum Load Interlock .....................................................................................................19

4.2.

Capacity Control Solenoid Valve Arrangements.................................................................20

4.3.

Capacity Control Arrangement Using Separate Pairs of Solenoid Valves..........................20

4.3.1.

Compressor Loading ..........................................................................................................20

4.3.2.

Compressor Unloading.......................................................................................................20

4.3.3.

Hold Slide Valve Position ...................................................................................................20

4.3.4.

Flow Control Valves............................................................................................................21

4.4.

Capacity Control Arrangement Using a 4-Way Solenoid Valve ..........................................23

4.4.1.

Compressor Loading ..........................................................................................................23

4.4.2.

Compressor Unloading.......................................................................................................23

4.4.3.

Hold Slide Valve Position ...................................................................................................23

4.4.4.

Flow Control Valves............................................................................................................23

4.5.

Capacity Control by Inverter Drive......................................................................................25

4.5.1.

Inverter Size .......................................................................................................................25

4.5.2.

Inverter Set-up....................................................................................................................25

4.6.

Linear Variable Displacement Transducer (LVDT) .............................................................26

4.7.

HB Linear Variable Displacement Transducer (HBLVDT) ..................................................26

4.7.1.

4 to 20 mA Calibration – Compressor Stopped ..................................................................26

4.7.2.

4 to 20 mA Calibration – Compressor Running ..................................................................27

4.7.3.

Fitting a New HBLVDT Electronics Module ........................................................................29

4.8.

MSI Linear Variable Displacement Transducer (MSI LVDT) ..............................................30

5.

Compressor Lubrication, Sealing and Cooling ......................................................... 32

HSO 2024 to HSO 2035 Installation, Operation and Maintenance Manual

Page 8 of 94 Publication 2-119 Issue 1.2 : 03/10

5.1.1.

Capacity Control Actuation .................................................................................................32

5.1.2.

Bearing Lubrication.............................................................................................................32

5.1.3.

Shaft Seal Lubrication, Sealing and Cooling ......................................................................32

5.1.4.

Oil Injection for Sealing and Cooling...................................................................................32

6.

Oil Support System ................................................................................................... 34

6.1.

Oil Injection/Lubrication ......................................................................................................34

6.2.

Oil Drain .............................................................................................................................34

6.2.1.

Oil Drain Sensor .................................................................................................................34

6.3.

Oil Separation.....................................................................................................................35

6.3.1.

Oil Separator Design ..........................................................................................................35

6.4.

Oil Separator Provisions.....................................................................................................35

6.4.1.

Oil Return ...........................................................................................................................36

6.4.2.

Suction/Discharge Non-return Valve ..................................................................................36

6.4.3.

Oil Heaters..........................................................................................................................36

6.4.4.

Oil Low Level ......................................................................................................................36

6.4.5.

Oil Balance Lines................................................................................................................36

7.

Oil Circulation............................................................................................................ 37

7.1.

Oil Differential Pressure Monitoring....................................................................................37

7.2.

Oil Differential Pressure 1 (ODP1)......................................................................................38

7.2.1.

Oil Flow Switch ...................................................................................................................39

7.2.2.

Oil Differential Pressure 2 (ODP2)......................................................................................39

7.2.3.

Oil System Differential Pressure Drop ................................................................................39

7.2.4.

Maintaining Discharge Pressure at Start up .......................................................................39

7.3.

Oil Filter ..............................................................................................................................40

7.4.

Compressor Cooling...........................................................................................................40

7.5.

Lubricating Oils...................................................................................................................41

8.

Prolonged Storage .................................................................................................... 42

8.1.

Placing the Compressor into Store.....................................................................................42

8.2.

Taking the Compressor out of Storage...............................................................................43

9.

Installing the Compressor ......................................................................................... 44

9.1.

Lifting the Compressor .......................................................................................................44

9.2.

Making Connections ...........................................................................................................44

9.3.

Electrical Wiring Connections and Interlocks......................................................................45

10.

Commissioning and Operation.................................................................................. 46

10.1.

Checks Prior to the First Start.............................................................................................46

10.2.

General Checks..................................................................................................................46

10.3.

Compressor Drive Motor ....................................................................................................47

10.4.

Checking Compressor Rotation..........................................................................................47

10.5.

Lubrication System .............................................................................................................48

10.6.

First Start............................................................................................................................48

10.7.

Normal Starting and Running .............................................................................................50

10.8.

Adding Oil to the System ....................................................................................................51

11.

Running-In the Compressor...................................................................................... 52

11.1.

Filters and Strainers ...........................................................................................................52

11.2.

Compressor Suction Strainer..............................................................................................52

11.3.

Oil Filter ..............................................................................................................................52

11.4.

Refrigerant Filter/Drier ........................................................................................................52

11.5.

Monitoring for Moisture.......................................................................................................52

11.6.

Lubricating Oil.....................................................................................................................52

11.7.

Checking for Leaks.............................................................................................................53

11.8.

Compressor Drive Motor Coupling .....................................................................................53

11.9.

Compressor and Drive Motor Holding-Down Bolts .............................................................53

12.

Pumping Down and Opening Up the Compressor.................................................... 54

12.1.

Preparing for Pump Down ..................................................................................................54

12.2.

Pumping Down the Compressor.........................................................................................54

12.3.

Isolating the Electrical Supply.............................................................................................54

12.4.

Removing the Residual Refrigerant Gas ............................................................................55

12.5.

Opening up the Compressor...............................................................................................55

HSO 2024 to HSO 2035 Installation, Operation and Maintenance Manual

Issue 1.2 : 03/10 Publication 2-119 Page 9 of 94

12.6.

Re-instating the Compressor..............................................................................................55

13.

Maintenance.............................................................................................................. 57

13.1.

Spare Parts.........................................................................................................................57

13.2.

Filters and Strainers ...........................................................................................................57

13.3.

Running-in ..........................................................................................................................58

13.4.

Maintenance Schedule .......................................................................................................58

13.5.

Maintenance Intervals ........................................................................................................58

13.5.1.

Daily...............................................................................................................................58

13.5.2.

Weekly ...........................................................................................................................59

13.5.3.

Monthly ..........................................................................................................................59

13.5.4.

Every Year, or at Intervals of 5,000 Operating Hours.....................................................60

13.5.5.

Every 3 Years, or at Intervals of 15,000 Operating Hours..............................................61

13.5.6.

Every 6 Years, or at Intervals of 25,000 Operating Hours..............................................61

13.5.7.

Every 12 Years, or at Intervals of 50,000 Operating Hours............................................61

13.5.8.

Every 24 Years, or at Intervals of 100,000 Operating Hours..........................................62

13.5.9.

Prolonged Shutdown......................................................................................................62

13.6.

Maintenance Check List .....................................................................................................62

13.7.

Oil Acid Content Record .....................................................................................................64

Appendix 1 Compressor Data ............................................................................................... 65

Appendix 2 Oil Support System Schematic Flow Diagrams ................................................. 73

Appendix 3 Limits of Operation Envelopes ........................................................................... 77

Appendix 4 HS 2000 Series Compressor Replacement Parts.............................................. 82

Appendix 5 Plant Performance Record................................................................................. 86

Appendix 6 Pepperl & Fuchs Signal Conditioning Module KFU8-USC-1.D Set-up.............. 88

List of Figures

Fig 1 Compression Process..................................................................................................................16

Fig 2 Capacity Control Slide Valve in Operation...................................................................................18

Fig 3 Capacity Control Arrangement Using Separate Pairs of Solenoid Valves ...................................22

Fig 4 Capacity Control Arrangement Using a 4-Way Solenoid Valve ...................................................24

Fig 5 HBLVDT Arrangement and External Wiring Connections............................................................27

Fig 6 HBLVDT External Wiring Connections for Explosion-Proof Version............................................28

Fig 7 MSI LVDT Arrangement and Wiring Connections .......................................................................30

Fig 8 Signal Conditioning Module.........................................................................................................31

Fig 9 Maintaining Discharge Pressure at Start up ................................................................................40

Fig 10 Lifting the Compressor...............................................................................................................44

Fig 11 Key to Schematic Flow Diagrams..............................................................................................73

Fig 12 No Oil Pump ..............................................................................................................................74

Fig 13 Start-up Oil Pump: Common Oil Lines for Injection and Lubrication..........................................75

Fig 14 Continuously Running or Demand Oil Pump: Common Oil Lines for Injection and Lubrication.76

List of Tables

Table 1 Capacity Control Solenoid Valve Options................................................................................20

Table 2 MSI LVDT/HBLVDT Part Number Cross-reference.................................................................31

Table 3 Pumping Capacities For Continuously Running Oil Pump.......................................................37

Table 4 Summary of Differential Pressure Sensing..............................................................................38

Table 5 Filter and Strainer Locations....................................................................................................58

Table 6 Maintenance Check List ..........................................................................................................63

Table 7 Oil Acid Content Record - Plants Charged with Refrigerant other than Ammonia (R717) .......64

Table 8 Basic Set up for 4 mA and 20 mA Output Values at Minimum

and Maximum Slide Valve Positions .......................................................................................89

Table 9 Setting the Display to Read 0 at Minimum Load and 100 at Maximum Load...........................91

Table 10 Setting the Relay Switch Value..............................................................................................92

HSO 2024 to HSO 2035 Installation, Operation and Maintenance Manual

Page 10 of 94 Publication 2-119 Issue 1.2 : 03/10

1. About this Publication

These instructions have been prepared according to the following

standards:

BS 4884 : Technical Manuals:

Part 1 : 1992 Specification for Presentation of Essential

Information.

Part 2 : 1993 Guide to Content.

Part 3 : 1993 Guide to Presentation.

BS 4899 : User’s Requirements for Technical Manuals:

Part 1 : 1991 Content.

Part 2 : 1992 Presentation.

BS 4899 is based on the principles of BS 4884.

BS 5378 : Part 2 : 1982 Safety Signs.

1.1. Safety Warnings and Symbols

The system of safety warnings and symbols is based on BS 5378 :

Part 2 : 1982 Safety Signs and BS 4884 : Technical Manuals : Part 1 :

1992 Specification for Presentation of Essential Information.

WARNING

This denotes an immediate hazard with a high likelihood

of personal injury or death if instructions, including

recommended precautions, are not followed. There is

also a potential risk of damage to the product, process

or its surroundings.

CAUTION

This draws attention to instructions which must be

complied with to avoid damage to the product, process

or its surroundings.

NOTE: draws attention to important additional

information.

1.2. Units of Measurement

Quantities are expressed in SI units or SI derived units.

1.3. Terminology

Terminology, abbreviations and acronyms are those currently in use

throughout the refrigeration and air conditioning industry.

1.4. Ordering Extra Copies

Obtain extra copies of these instructions from the address below:

J & E Hall International Telephone: +44 (0) 1322-394420

Questor House, Fax: +44 (0) 1322-425161

Dartford, Website: www.jehall.co.uk

Kent DA1 1PU

England

HSO 2024 to HSO 2035 Installation, Operation and Maintenance Manual

Issue 1.2 : 03/10 Publication 2-119 Page 11 of 94

2. Misuses that Invalidate Guarantee

Please note that the installer is responsible for the correct installation and

commissioning of equipment and, on completion, the owner and/or user

is responsible for its safe operation and maintenance.

Failure to comply with the following provisions will invalidate the

guarantee as set out in J & E Hall International standard conditions of

sale.

2.1. Application

The following is specifically prohibited:

(a) Operation outside the limits detailed in Appendix 1 Compressor

Data.

(b) Use of any anti-freeze, trace chemical or other additive in the

primary refrigerant system.

(c) Use of lubricating oils other than those specified by J & E Hall

International; refer to publication 2-59 Lubricating Oils.

2.2. System Provisions

Refer to Appendix 2 Oil Support System Schematic Flow Diagrams.

Items specifically required and which are considered mandatory are as

follows:

(a) On all systems other than those using R717 (ammonia), fit an

adequately sized refrigerant filter/drier, preferably of the type using

renewable cores. Fit a sight-glass/moisture indicator.

(b) Fit an adequately sized oil filter for filtration to 10 micron (10µ) or

better: β25≥75, β10≥3, β5> 1.

(c) Fit an adequately sized suction strainer having a mesh aperture of

250µor better.

(d) If the system is fitted with an economiser, fit an adequately sized

strainer in the economiser suction line. The strainer must have a

mesh aperture of 250µor better.

(e) To prevent excessive reverse rotation of the compressor at

shutdown it is necessary to fit a non-return valve adjacent to the

compressor in the suction and/or discharge lines:

•Single compressor application - either a suction or discharge

non-return valve must be fitted. A non-return valve in the

suction line must be located before the suction strainer.

•Multiple compressor application - all compressors must be

fitted with a discharge non-return valve.

NOTE: discharge non-return valves must be sized

according to the operating conditions.

(f) Adequate precautions must be taken to prevent oil or liquid

refrigerant accumulating in the compressor when it is stopped;

refer to 6.2. Oil Drain.

(g) The compressor will need cooling; refer to the HSO 2000 Series

Compressor Application Manual and publication 2-122 Compressor

Cooling, available from J & E Hall International.

If liquid injection cooling or thermosyphon oil cooling is used, a

preferential supply of liquid refrigerant must be provided for cooling

purposes. The priority supply must be arranged so that the cooling

requirement is satisfied before liquid can flow to the evaporator(s);

refer to publication 2-122 Compressor Cooling.

(h) Fit, and maintain in an operational condition, the cut-outs and other

safety devices described in ,Appendix 1 Compressor Data

illustrated in Appendix 2 Oil Support System Schematic Flow

Diagrams.

HSO 2024 to HSO 2035 Installation, Operation and Maintenance Manual

Page 12 of 94 Publication 2-119 Issue 1.2 : 03/10

Under no circumstances should the compressor be operated with

cut-outs or other safety devices short-circuited or rendered

inoperative by mechanical or electrical means.

(i) The plant controller is required to supply load/unload pulses to the

capacity control solenoid valves; refer to 4. Capacity Control .

The control system must be interlocked to prevent the compressor

starting unless the slide valves are at minimum load; refer to 4.1.1.

Minimum Load Interlock.

For capacity control modulation, flow control valves must be fitted

in the load and unload oil lines to and from the capacity control

cylinder; refer to Fig 3 and Fig 4.

2.3. Prolonged Storage

If, for any reason, the compressor cannot be installed immediately and

must be placed in prolonged storage, refer to 8. Prolonged Storage.

2.4. Commissioning Provisions

General commissioning procedures are described in 10. Commissioning

and Operation.

The following provisions are considered mandatory:

(a) The system into which the compressor is installed must be

dehydrated by evacuation to a pressure of no more than

2.0 mm Hg before charging and commissioning take place. Under

no circumstances must the HallScrew compressor be used to

evacuate or pump out the system.

The evacuation procedure is described in publication Part E :

Evacuation and Dehydration, available from J & E Hall

International.

NOTE: it is important to remember that evacuating the

system does not remove moisture dissolved in

synthetic ester lubricant; refer to (c).

(b) When a mineral oil is specified for compressor lubrication, maintain

the acid number of the oil <0.05 by checking on a regular basis

using a proprietary acid test kit.

(c) With HFC refrigerants, for example, R134a or R404a, it is

necessary to use polyolester synthetic lubricants. Maintain the

acid number of the compressor lubricating oil <0.15 by checking

the oil on a regular basis using a proprietary acid test kit available

from the oil supplier.

When using polyolester synthetic oils, care must be taken to

ensure that contact between air and the lubricant is minimised.

Spare oil must be adequately protected against contamination;

refer to 10.8. Adding Oil to the System.

NOTE: compressor failure due to internal corrosion,

copper plating, sludged oil or etching of internal

components due to high acidity will be taken as

evidence that the above provisions have not been

complied with.

(d) Connect the compressor drive motor such that the compressor

rotates anticlockwise when looking on the compressor shaft end

(driven end); refer to 10.4. Checking Compressor Rotation.

HSO 2024 to HSO 2035 Installation, Operation and Maintenance Manual

Issue 1.2 : 03/10 Publication 2-119 Page 13 of 94

3. General Description

The J & E Hall International HSO 2000 series of open drive compressors

form part of the HallScrew family of positive displacement, oil injected,

single screw compressors.

These compressors have been specially developed for refrigeration, air

conditioning and heat pump applications, and can be applied to single

stage and multi-stage systems using all normal refrigerants as well as

many other process gases.

3.1. Main Features

•For use with R717 (ammonia), R22, R404a, R507A, R134a,

R407c, R410a and R23.

•Designed and tested to international standards.

•Robust construction.

•Improved machine clearance control for maximum efficiency.

•Oil injected for maximum reliability.

•Balanced loading on main bearings for maximum bearing

life.

•Enhanced slide valve geometry for capacity modulation with

minimum loss of efficiency. Infinite adjustment between

maximum (100 %) and minimum load (nominal 10 %).

•Economiser facility provided to improve operating efficiency,

especially at high compression ratios.

For further information refer to publication 2-129 Economiser

Facility For HallScrew Compressors.

•Anti-clockwise rotation looking on the motor (driven) end.

Intermediate gearbox required for gas engine drive.

3.2. Construction

The motion work, i.e. that part of the machine which performs the

compression function, consists of three rotating parts; there are no

eccentric or reciprocating motions. These fundamental components

comprise the cylindrical main rotor in which are formed six-start, helically

grooved screw threads with a spherical (hourglass) root form. The main

rotor meshes with two identical toothed wheels each having eleven teeth.

These wheels (or 'star rotors' as they are called owing to their shape), are

made from a special synthetic material. They are located in a single

plane diametrically opposite each other on either side of the main rotor

with their axes at right-angles to the main rotor axis. As the main rotor

turns, it imparts a freely rotating motion to the star rotors.

The star rotors are supported by metal backings which are cast in one-

piece with the star rotor shafts. Although they are located in place on

their backings, the stars are allowed to 'float' a small amount in a

rotational sense. This floating action, combined with the low inertia and

negligible power transmission between the main rotor and star rotors,

effectively absorbs any minute vibrations of the star/main rotor

combination. The star rotor shafts are supported at each end by taper

roller bearings.

The main rotor is a dynamically balanced component, manufactured from

cast-iron, keyed to the steel mainshaft which runs in rolling element main

bearings. Where the shaft emerges from the casing, leakage of oil or

refrigerant is effectively prevented by a specially designed mechanical

seal.

HSO 2024 to HSO 2035 Installation, Operation and Maintenance Manual

Page 14 of 94 Publication 2-119 Issue 1.2 : 03/10

The main rotor and star rotors are housed inside a one-piece, cast-iron

main casing. The inside of the casing has a somewhat complex shape,

but essentially consists of a cylindrical annulus which encloses the main

rotor leaving a small clearance. Part of the annulus is cutaway at the

suction end to allow the star teeth to mesh with the main rotor flutes. The

discharge ports (one for each star), are positioned at the other end of the

annulus. These ports convey the compressed gas into the discharge

manifold, formed by a web cast between the annulus and the walls of the

casing; this web separates the casing into two pressure zones. Except

for the discharge manifold, suction pressure prevails elsewhere in the

main casing.

Side covers are provided to allow easy access to the star rotors, star

rotor shafts and bearings, without disturbing working tolerances. The

discharge end cover can also be removed to inspect the capacity control

mechanism. The compressor is provided with the choice of either top or

bottom discharge; the unused connection is sealed off with a blank cover.

It is necessary to fit a suction strainer immediately before the compressor

suction inlet. The strainer is designed to trap any dirt circulating with the

refrigerant which might otherwise enter and damage the compressor.

To prevent reverse rotation of the compressor at shutdown it is necessary

to fit a non-return valve adjacent to the compressor in the suction and/or

discharge lines; refer to 6.4.2.

3.3. The Compression Process

In the construction of the HallScrew the helical flutes in the main rotor can

be likened to the cylinders of a reciprocating compressor, the star rotor

teeth taking the place of conventional pistons. Instead of using suction

and discharge valves, gas flow in and out of the flutes (the cylinders) is

controlled by fixed ports.

Gas enters the compressor through the suction connection and fills the

available flutes. Rotation of the main rotor traps the gas in chambers

formed by the flute walls, the cylindrical annular ring housing the main

rotor, and the star teeth. The small clearances around the star teeth are

sealed with oil which is injected into the compressor during operation. As

the main rotor turns, the star teeth act as stationary pistons in the moving

flutes (the cylinders), and the gas is compressed until a discharge port is

uncovered. Each flute is used twice per rotor revolution, i.e. once by one

tooth on each star.

The compression process is illustrated and described in detail in Fig 1.

As the compression process is symmetrical, occurring at the same instant

in each half of the compressor, this results in zero transverse gas

pressure loads on the main rotor bearings. The axial loads are also

minimal because the flutes terminate on the outer surface of the main

rotor. The only bearing loads, apart from the weight of parts, are bending

loads on the star rotor shaft bearings due to high pressure gas acting on

one side of each tooth in mesh. There is also a small axial thrust load on

the main rotor bearings resulting from the main shaft projecting through

the casing, combined with the rotor vent pressure.

Capacity control is effected by slide valves, one for each half of the

compressor. These valves are used to vent part of the gas trapped in the

flutes back to suction, thus effectively shortening the compression length

of the main rotor. Using this method, compressor capacity is infinitely

variable between 100 % and 10 % of full load.

HSO 2024 to HSO 2035 Installation, Operation and Maintenance Manual

Issue 1.2 : 03/10 Publication 2-119 Page 15 of 94

The movement of the slide valves is effected by oil pressure acting on a

piston which is connected to the valves by a yoke. Pressurised oil is

taken from the lubrication system and fed through solenoid valves which

respond to signals from the plant control system. The solenoid valves

direct oil to each end of the compressor capacity control cylinder via two

connections positioned at the rear of the main casing, moving the

capacity control piston in the appropriate direction to load or unload the

compressor. Oil from the other end of the capacity control cylinder is

vented to the low pressure (LP) side of the system via a connection in the

suction line before the suction non-return valve.

HSO 2024 to HSO 2035 Installation, Operation and Maintenance Manual

Page 16 of 94 Publication 2-119 Issue 1.2 : 03/10

1.

S

UCTION

2.

S

UCTION

Fig 1 Compression Process

3.4. The Compression Process

As the HallScrew is a positive displacement compressor, there are three

separate stages in the compression cycle: suction, compression and

discharge. These are illustrated in Fig 1.

3.4.1. Suction

Main rotor flutes 'a', 'b' and 'c' are in communication at one end with the

suction chamber via the bevelled rotor end face, and are sealed at the

other end by the teeth of star rotor A. As the main rotor turns, the

effective length of the flutes increases with a corresponding increase in

the volume open to the suction chamber: Diagram 1 Fig 1 clearly shows

this process. As flute 'a' assumes the position of flutes 'b' and 'c' its

volume increases, inducing suction vapour to enter the flute.

Upon further rotation of the man rotor (diagram 2 Fig 1), the flutes which

have been open to the suction chamber engage with the teeth of the

other star rotor. This coincides with each flute being progressively sealed

by the cylindrical annulus housing the main rotor (the outline of the

annulus is shown as dotted lines). Once the flute volume is closed off

from the suction chamber, the suction stage of the compression cycle is

complete.

a

b

c

a

b

c

ab

ab

B

A

B

A

HSO 2024 to HSO 2035 Installation, Operation and Maintenance Manual

Issue 1.2 : 03/10 Publication 2-119 Page 17 of 94

3.

C

OMPRESSION

4.

D

ISCHARGE

Fig 1 (continued) Compression Process

3.4.2. Compression

As the main rotor turns, the volume of gas trapped within the flute is

reduced as the length of the flute shortens and compression occurs.

3.4.3. Discharge

As the star rotor tooth approaches the end of a flute, the pressure of the

trapped vapour reaches a maximum value occurring when the leading

edge of the flute begins to overlap the triangular shaped discharge port.

Compression immediately ceases as the gas is delivered into the

discharge manifold. The star rotor tooth continues to scavenge the flute

until the flute volume is reduced to zero. This compression process is

repeated for each flute/star tooth in turn.

While the compression process described above is occurring in the upper

half of the compressor, there is an identical process taking place

simultaneously in the lower half using star B, thus each main rotor flute is

used twice per rotor revolution (one by one tooth in each star). The

compression process may be likened to an assembly of six double-acting

cylinders (the main rotor flutes) in which the star rotor teeth move as

pistons (always in the same direction).

a

b

c

a

b

a

b

c

a

b

B

A

B

A

HSO 2024 to HSO 2035 Installation, Operation and Maintenance Manual

Page 18 of 94 Publication 2-119 Issue 1.2 : 03/10

4. Capacity Control and Volume Ratio

Since the HallScrew compressor utilises fixed intake and discharge ports

instead of valves, the overall compression ratio is determined by the

configuration of these ports. The degree of compression is governed by

the ratio between the flute volume when it is sealed off by the star tooth

at the beginning of the compression process, to that immediately before

the delivery port is uncovered. This is known as the built-in volume ratio

(V

R

) and is an important characteristic of all fixed-port compressors.

In order to achieve maximum efficiency, the pressure within the flute

volume at the end of the compression process should equal the pressure

in the discharge line at the instant the flute volume opens to discharge.

Should these conditions not prevail, either overcompression or

undercompression will occur, both of which result in internal losses.

Although in no way detrimental to the compressor, inefficient

compression will increase power consumption.

Fig 2 Capacity Control Slide Valve in Operation

Suction Gas

Suction Gas

Bypass

Discharge

Discharge

Slide valves in fully loaded position

Slide valves in part load position

Main Rotor

Main Rotor

HSO 2024 to HSO 2035 Installation, Operation and Maintenance Manual

Issue 1.2 : 03/10 Publication 2-119 Page 19 of 94

The best part load characteristics are achieved if the design full load V

R

is

maintained as the compressor’s capacity is reduced. The HallScrew

2000 series compressor is fitted with a pair of sliding valves, one for each

half of the symmetrical compression process. These valves reduce

pumping capacity by delaying the sealing of the flute volume together

with the opening of the discharge port, altering the effective length of the

main rotor flutes. The valves not only permit stepless capacity control

down to approximately 10 % of full load (actual minimum value varies

with operating conditions), but also maintain the best possible V

R

over a

wide capacity control range.

Each slide valve is housed in a semicircular slot in the wall of the annular

ring which encloses the main rotor. As the slide valve travels axially from

the full load position it uncovers a port which vents part of the gas

trapped in the main rotor flute back to suction before compression can

begin. When the flute has passed beyond the port, compression

commences with a reduced volume of gas. However, a simple bypass

arrangement without any further refinement would produce an

undesirable fall in the effective volume ratio which in turn causes

undercompression and inefficient part load operation. To overcome this

problem, the slide valve is shaped so that it reduces the discharge port

area at the same time as the bypass slot is created.

Fig 2 shows one of the capacity control slide valves in two positions: fully

loaded and at part load, the arrows on the diagram indicating the flow of

gas. Each half of the compressor is provided with its own slide valve

system, these are operated simultaneously to maintain balanced gas

loads and low bearing loads within the compressor. The position of the

slot at the suction end of the slide and the position of the moving delivery

port can both be chosen to give the desired full load V

R

, the appropriate

ratio being selected according to the operating conditions. The following

volume ratio slides are available for each compressor size: 1.85, 2.2, 2.6,

3.5 and 4.9.

4.1. Slide Valve Actuation

The capacity control slides valves are joined together by a yoke which is

connected to a hydraulic piston, housed inside a cylinder and mounted

internally at the discharge end of the compressor.

The motive force required to actuate the piston is derived from a supply

of pressurised oil taken from the lubrication system. The flow of oil to the

cylinder is controlled either by a specially adapted 4-way solenoid valve

or by two pairs of solenoid valves connected in parallel. As the

requirement for duty changes, the plant control system energises or de-

energises the solenoid valves, supplying oil pressure to drive the piston

and slide valves in the load or unload direction. The oil on the other side

of the piston is vented to the evaporator side of the suction non-return

valve via a drain line.

The capacity control piston/slide valves speed of travel, and hence how

quickly the compressor loads and unloads, is determined by flow control

valves fitted in the load and unload oil lines to the capacity control

cylinder.

4.1.1. Minimum Load Interlock

Starting at minimum load minimises motor starting current and starting

torque. This in turn minimises stresses on the motor and mechanical

parts, and also reduces the load on the power supply network.

The control system must be interlocked to prevent the compressor

starting unless the linear variable displacement transducer (LVDT)

provides an ‘at minimum load’ permit start signal.

If the slide valves are not already at minimum load, the pressure

generated by the system oil pump is used to return them to the minimum

load position.

HSO 2024 to HSO 2035 Installation, Operation and Maintenance Manual

Page 20 of 94 Publication 2-119 Issue 1.2 : 03/10

4.2. Capacity Control Solenoid Valve Arrangements

As discussed in 7. Oil Circulation, if the system suction/discharge

pressure differential is sufficient to generate oil pressure for injection and

lubrication, an oil circulation pump can be dispensed with altogether.

However, as there is no other oil pressure source, special precautions

must be taken to automatically return the capacity control piston to the

minimum load position when the compressor stops to provide a

‘compressor on minimum load’ interlock permit start signal for the next

start. Therefore, instead of a 4-way solenoid valve, it is necessary to use

two pairs of solenoid valves connected in parallel as illustrated in Fig 3.

In this arrangement the solenoid valves in the unload path are reverse

acting, i.e. energise to close. Hence when the compressor stops for

whatever reason, and especially in the event of power failure, these

valves will always de-energise (open) and unload the compressor.

The arrangement using separate pairs of solenoid valves must be used if

the compressor is located in a Zone 1 or Zone 2 hazardous area where

explosion-proof coils are a mandatory requirement. These coils cannot

be fitted to the 4-way valve. The various capacity control solenoid valve

options are summarised in Table 1.

A

PPLICATION

C

APACITY

C

ONTROL

S

OLENOID

V

ALVE

A

RRANGEMENT

No oil pump Use separate pairs of solenoid valves

Oil pump runs at start-up only A 4-way valve or separate pairs of solenoid valves can be

used

Continuously running or demand oil pump

All oil pump applications - compressor located in a Zone 1 or

Zone 2 hazardous area

Use separate pairs of solenoid valves fitted with Valvex

explosion-proof coils

Table 1 Capacity Control Solenoid Valve Options

4.3. Capacity Control Arrangement Using Separate Pairs of Solenoid

Valves

This arrangement, shown in Fig 3, provides continuously variable

capacity control between minimum and maximum load. There are two

pairs of solenoid valves connected in parallel:

•Solenoid valves X and Y are normally open (NO), energise

to close.

•Solenoid valves W and Z are normally closed (NC), energise

to open.

4.3.1. Compressor Loading

With all the solenoid valves energised, valves W and Z are open, X and Y

are closed. Pressurised oil flows through valve W into the load side of

the capacity control cylinder, forcing the piston and slide valves in the

load direction and increasing compressor pumping capacity. Oil on the

unload side of the piston is forced through valve Z and drains to suction.

4.3.2. Compressor Unloading

With all the solenoid valves de-energised, valves W and Z are closed, X

and Y are open. Pressurised oil flows through valve X into the unload

side of the capacity control cylinder, forcing the piston and slide valves in

the unload direction and decreasing compressor pumping capacity. Oil

on the load side of the piston is forced through valve Y and drains to

suction.

4.3.3. Hold Slide Valve Position

When solenoid valves X and Y are energised, valves W and Z de-

energised, all the valves are closed, hydraulically locking the capacity

control piston and slide valves at the desired load position.

This manual suits for next models

4

Table of contents

Popular Air Compressor manuals by other brands

California Air Tools

California Air Tools 2010A owner's manual

TOOLCRAFT

TOOLCRAFT KLK-118 Original operating instructions

MayPole

MayPole MP7949 manual

Sullair

Sullair TS-20 Operator's manual and parts list

Doosan

Doosan P600/XP535WCU-T4i Operation and maintenance manual

Gardner Denver

Gardner Denver EBB BB-7.5 HP Operating and service manual

Craftsman

Craftsman 919.195400 Operator's manual

ULTIMATE SPEED

ULTIMATE SPEED UMK 10 C2 Operation and safety notes translation of the original instructions

Craftsman

Craftsman 919.167462 owner's manual

Gast

Gast 120R Operation and maintenance manual

Bitzer

Bitzer ST-150-2 technical information

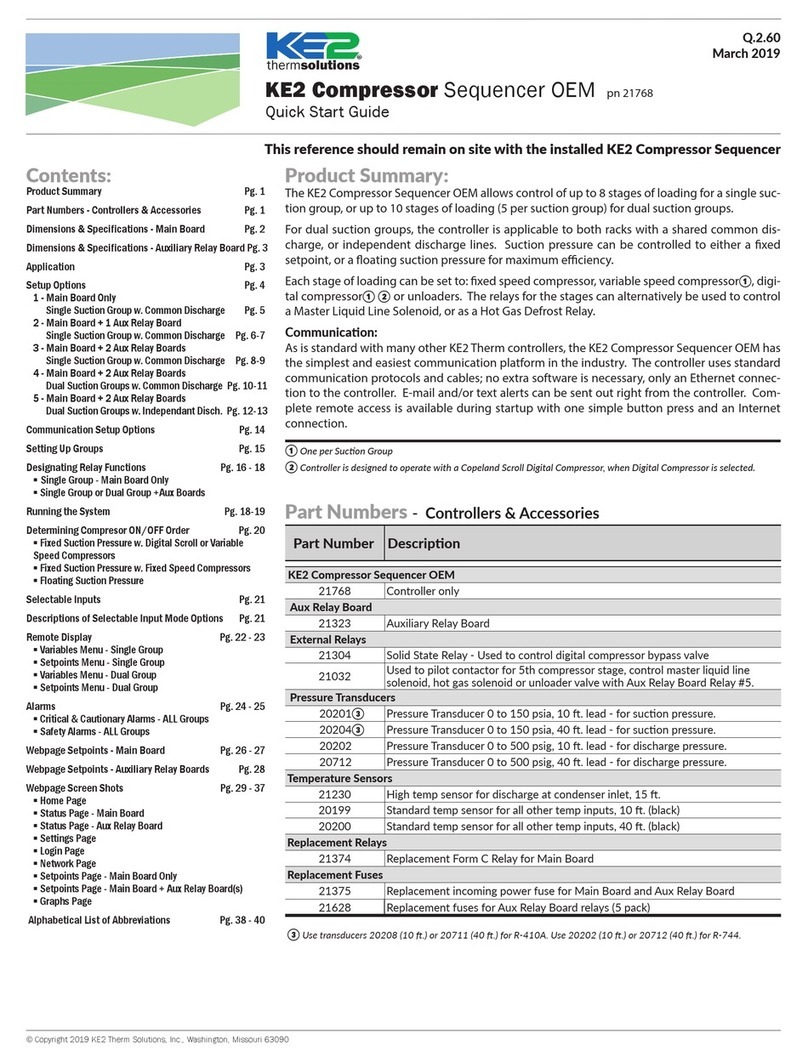

KE2

KE2 Compressor Sequencer OEM quick start guide