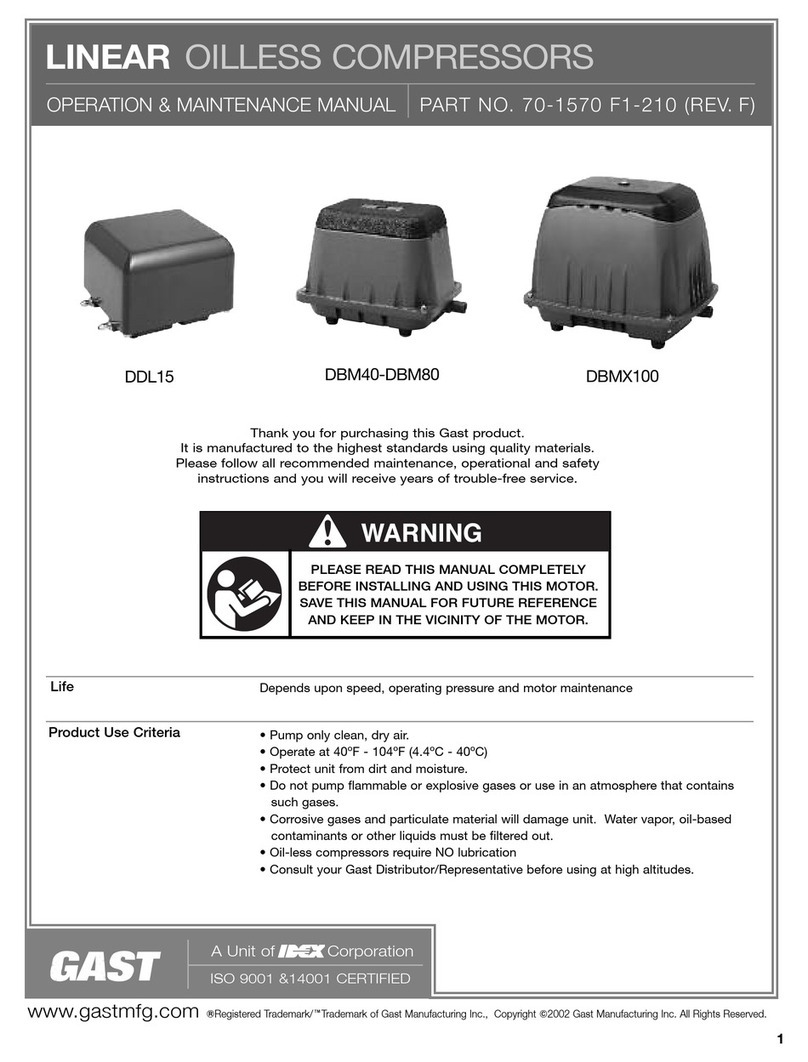

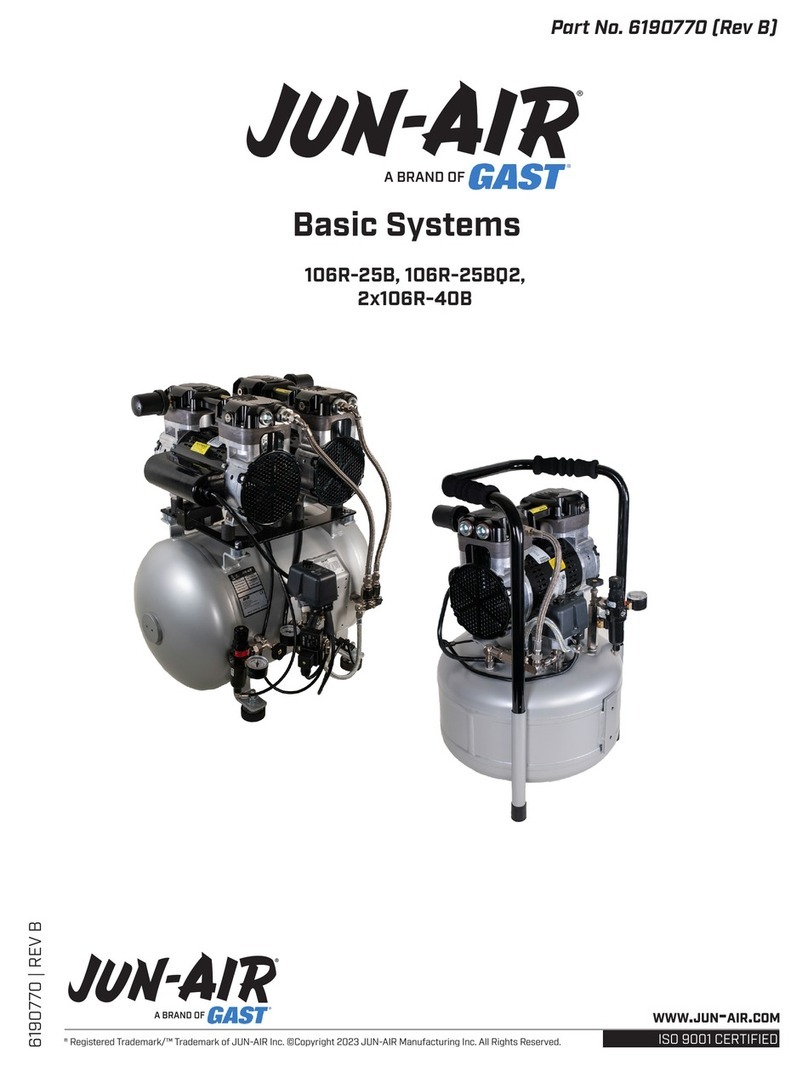

Gast JUN-AIR 120R-40B User manual

Part No. 6190760 (Rev A)

Compressor

120R-40B, 120R-40BQ3

2x120R-90BQ6

6190760 | REV A

® Registered Trademark/™ Trademark of JUN-AIR Inc. ©Copyright 2022 JUN-AIR Manufacturing Inc. All Rights Reserved.

WWW

.

JUN

-

AIR

.

COM

ISO 9001 CERTIFIED

A BRAND OF

®

A BRAND OF

®

2

6190760 (Rev A) 120R Basic Compressor User Guide

© 2022 JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

Table of Contents

DB Operating Manual ................................................................................................. 5

DE Betriebsanweisung ............................................................................................... 5

FR Mode d’emploi .................................................................................................... 5

ES Modo de empleo................................................................................................... 5

NL Gebruiksaanwijzing ................................................................................................ 5

DK Betjeningsforskrift ................................................................................................ 5

Technical specifications

Technische Daten

Caracteristiques techniques

Detalles téchnicos

Technische gegevens

Tekniske specifikationer

Diagrams

Zeichnungen

Dessins

Diagramas

Tekeningen

Diagrammer

Spare parts

Ersatzteile

Pieces detachées

Piezas de recambio

Onderdelenlijst

Reservedele

3

© 2022, JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

120 Basic Compressor User Guide 6190760 (Rev A)

Warranty

Provided that the instructions for operation, maintenance and

service have been carried out, your JUN-AIR compressor is

guaranteed against faulty material or workmanship for 2 years.

The air receiver is guaranteed for 5 years.

The guarantee does not cover damage caused by violence,

misuse, incorrect repairs or use of unoriginal spare parts. Costs

of transportation of parts/equipment are not covered by the

guarantee.

JUN-AIR’s Conditions for Sale and Delivery will generally apply.

JUN-AIR International A/S reserves the right to change technical

specifications/constructions.

DE – Garantie

Vorausgesetzt, dass die Anweisungen für Betrieb und

Wartungerfüllt sind, gewährt JUN-AIR 2 Jahre Garantie bei

Materialoder Fertigungsfehlern.

Auf den Druckbehälter gewährt JUN-AIR 5 Jahre Garantie.

Ausgenommen von Garantieleistungen sind Schäden die durch

Gewalt, falsche Bedienung, nicht fachgerechte Reparaturen oder

durch Verwendung nicht originaler Ersatzteile verursacht wurden.

Transportkosten sind von der Garantie ausgeschlossen.

Es gelten die allgemeinen Geschäfts- und Lieferbedingungen von

JUN-AIR.

JUN-AIR behält sich das Recht von technischen Änderungen vor.

FR – Garantie

Celle-ci s’applique à toutes les pièces défectueuses et les vices

de fabrication pendant 2 ans d’utilisation, à condition que les

instructions d’emploi aient été correctement appliquées.

La garantie sur la cuve est de 5 ans.

Sont exclus de la garantie: L’utilisation de pièces détachées non

d’origine. Les dommages résultant de réparations négligées, d’un

manque d’entretie’n, d’utilisation incorrecte ou de violence. Les

frais de transport de pièces/matériel ne sont pas couverts par la

garantie.

Sauf accord contraire, les Conditions Générales de Vente et de

Livraison de JUN-AIR International A/S seront appliquées.

JUN-AIR International A/S se réserve le droit de changer les

spécifications techniques/la construction.

ES – Garantia

Su compresor JUN-AIR está garantizado durante 2 años contra

fallos de materiales o de construcción, siempre que se cumplan

las instrucciones de uso.

El tanque está garantizado durante 5 años.

La garantia no cubre los daños causados por violencia, mala

utilización, reparaciones incorrectas o uso de recambios no

originales. El coste de transporte de recambios o equipos no está

cubierto por la garantia.

Las Condiciones Generales de Venta y Entrega de JUN-AIR

International A/S serán aplicables.

JUN-AIR International A/S se reserva el derecho a cambiar las

especificaciones técnicas o de construcción sin aviso.

NL – Garantie

Op de JUN-AIR compressor geven wij een garantie van 2 jaar op

materiaal- en constructiefouten, onder de voorwaarde dat u zich

aan de gebruiksaanwijzing heeft gehouden.

De garantie op het drukvat bedraagt 5 jaar.

De garantie is niet van toepassing op schade die het gevolg is van

geweld, onjuist gebruik, onvakkundige reparaties of gebruik van

niet originele onderdelen. Kosten van transport van onderdelen

vallen niet onder de garantie.

De verkoop- en leveringsvoorwaarden van JUN-AIR International

A/S zijn van toepassing.

JUN-AIR International A/S behoudt zich het recht voor

technische gegevens te wijzigen.

DK – Garanti

Under forudsætning af at alle betjenings- og serviceforskrifter

overholdes, ydes der 2 års garanti for alle materiale- og

fabrikationsfejl.

Dog ydes der 5 års garanti for beholdergennemtæring.

Garantien omfatter ikke skader, som skyldes vold, misbrug,

fejlagtige reparationer eller uoriginale reservedele.

Transportomkostninger er ikke omfattet af garantien.

For Skandinavien gælder i øvrigt NL 92 Salgs- og

Leveringsbetingelser.

JUN-AIR International A/S forbeholder sig retten til ændringer i

tekniske specifikationer og konstruktion.

4

6190760 (Rev A) 120R Basic Compressor User Guide

© 2022 JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

SAFETY

Important - read this first!

Please read the following information and operating instructions

included with this product before use. This information is for your

safety and it is important that you follow these instructions. It will

also help prevent damage to the product. Failure to operate the unit

in accordance with the instructions or using JUN-AIR unauthorized

spare parts can cause damage to the unit and could cause serious

injury.

CAUTION: To reduce risk of electric shock

• Only authorized service agents should carry out service.

Removing parts or attempting repairs can create an electric

shock. Refer all servicing to qualified service agents.

• If this unit is supplied with a three-pin plug, connect with a

properly earthed outlet only.

WARNING: To reduce risk of electrocution

• Do not use this unit with electrical voltages other than stated

on the rating plate.

• Always unplug this unit immediately after use and store in a dry

place.

• Do not use this product in or near liquid or where it can fall or

be pulled into water or other liquids.

• Do not reach for this product if it has fallen into liquid. Unplug

immediately.

• This unit is not weatherproof. Never operate outdoors in the

rain or in a wet area.

DANGER: To reduce risk of explosion or fire

• During spraying with combustible liquids, risk of explosion may

arise, particularly in closed rooms.

• Do not use this product in or near explosive atmospheres or

where aerosol products are being used.

• Do not pump any other gases other than atmospheric air.

• Do not pump combustible liquids or vapours with this product;

do not use it in or near areas with combustible or explosive

liquids or vapours.

• Do not use this unit near open flames..

CAUTION: To prevent injury

• Compressed air can be dangerous; do not direct airflow at

a person’s head or body.

• Always keep the system out of reach of children.

• Never operate this product if it has a damaged power lead or

plug, if it has been dropped or damaged, or if it has fallen into

water. Return the product to a service center for examination

and repair.

• Keep the electrical cable away from hot surfaces.

• Ensure all openings are kept free of restriction and never

restart when the unit cools and the overload resets.

Never place the system on a soft surface where

the openings may be blocked. Keep all openings free from

dust, dirt and other particles.

• Never leave this product unattended when plugged in.

• Never insert fingers or any other objects into fans.

• This unit is thermally protected and can automatically restart

when the overload resets.

• Wear safety glasses, when servicing this product.

• Use only in well ventilated areas.

• This product may only be connected to units or tools with a

max. pressure rating higher or equal to that of the compressor.

• The surface of the compressor can get hot. Do not touch

compressor motor during operation.

Failure to observe the safety precautions could result in severe

bodily injury, including death in extreme cases.

IMPORTANT: General directions for use

• Protect compressor against rain, moisture, frost and dust.

• The compressor is constructed and approved for a max.

pressure as stated under Technical Specifications.

• Do not operate the compressor at ambient temperatures

exceeding 40°C/104°F or falling below 0°C/32°F.

• If the supply power lead on the compressor is defective, an

authorized Jun-Air distributor or other qualified personnel

must carry out the repair.

5

© 2022, JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

120 Basic Compressor User Guide 6190760 (Rev A)

OPERATION

• If the compressor has been stored at an extremely low

temperature, allow it to heat to room temperature before

switching it on.

• If the compressor is supplied with a receiver, connect equipment

and open the filter regulator on the receiver.

• Turn on the compressor on the pressure switch.

• The compressor will automatically stop when the preset cut-out

pressure is reached.

• If the compressor does not start, there might be pressure in

the receiver. The compressor will automatically start when the

pressure drops.

• The cut-in and cut-out pressure is preset from the factory and

it is normally not necessary to change this. However, if it is

necessary to change the preset settings, the instructions of this

manual shall be followed carefully.

• All AC compressors are designed for 100% duty but 50%

operation is recommendable to prolong the lifetime.

• Do not remove the protection covers during operation as it may

cause electric shock or other personal injury.

• Do not lubricate the oil-less motor with oil, as it will destroy

important components.

MAINTENANCE

To ensure a long lifetime of the compressor, it is important that

inspection and maintenance is carried out regularly as described in

the following.

Preventive maintenance

Activity Weekly Monthly

One a year,

or every

2000 hours

aDrain condensate •

bCheck filter regulator •

cCheck for leaks •

dClean the unit •

eCheck safety valve •

fCheck inlet filter •

gCheck non-return

valve •

a) Drain condensate

Drain condensate by opening the drain cock on the receiver.

If mounted with auto drain, condensate will be drained

automatically. If drain bottle is installed, empty when necessary.

b) Check filter regulator

If a filter regulator is installed, check weekly and drain for

condensate by pressing the button at the bottom.

If auto drain is installed, the filter will be emptied automatically.

Check and change the filter and filter element in accordance with

the instructions in “Installation and maintenance instructions” for

the filter in question.

c) Check for leaks

Check motor, hoses and equipment for leaks.

Check the pumping time.

d) Clean the unit

Clean the unit when needed with a soft, damp cloth. If necessary,

use paraffin to remove adhesions. Dust and dirt prevent cooling.

e) Check safety valve

Check the safety valve with pressure in the receiver. The safety valve

is operated by pulling the ring (1) or turning the screw (2) depending

on the valve type.

6

6190760 (Rev A) 120R Basic Compressor User Guide

© 2022 JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

f) Check intake filter

Check the intake filter and change it if necessary.

Remove the filter and replace.

g) Check the non-return valve

Turn off the compressor on the mains switch and pull out the

plug.

Empty the receiver for compressed air by operating the safety

valve. When the receiver is empty, the reading of the pressure

gauge is bar.

Dismount the non-return valve from the receiver.

Disassemble the non-return valve and remove the O-ring ()

from the piston.

Clean the non-return valve.

Mount a new O-ring and re-assemble the non-return valve.

Re-install the non-return valve.Service

Please note that all service must be carried out by a qualified

person.

Adjustment of pressure switch

The working presure has ben preset from the factory, and it is

normally not necessary to change this.

However, if it is necessary to change the preset settings, the

instructions mentioned below should be followed carefully.

Warning

The compressor is constructed and approved for a max.

pressure as stated under Technical Specifications - do not

adjust to a higher pressure.

Higher working pressure will reduce the lifetime of the

compressor.

The compressor will stop at max. pressure (stop pressure) and

start again at min. pressure (start pressure). The difference

between max. and min. pressure is the differens pressure.

Unscrew the lid of the pressure switch. Adjust max. pressure

adjusting the two springs marked A (clockwise: higher pressure).

Adjust the two springs identically.

Adjust the differens pressure adjusting the spring marked B

(clockwise: higher differens pressure, start pressure maintained).

Test of pumping time

The pumping time indicates the condition of the compressor.

. Check that there are no leaks in the system.

. Empty the air receiver of compressed air so that the

pressure gauge shows bar.

. Close the filter regulator and check that the drain valve is

closed.

. Start the compressor and note the time it takes until it is

turned off again by the pressure switch. Check that the

pumping time agrees with the technical specifications for

the actual compressor system.

Please note that the pumping time in this manual is given for to

max pressure. Deviations from this result in deviating results.

Important

Always test the pumping time when cold. If the compressor is

warm, the pumping time will be considerably longer.

7

© 2022, JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

120 Basic Compressor User Guide 6190760 (Rev A)

FAULT FINDING AND REPAIR

Important

Switch off and isolate from electrical supply before removing

any parts from the pump. Empty air receiver of air before

performing any operation on the compressors’ pressure

system.

1. Compressor does not start

a. The air receiver is pressurized. The motor will start when

the pressure has dropped to the preset start pressure.

Empty the receiver.

b. Check that the mains supply agrees with the motor

label.

c. No power from mains. Check fuses and plug.

d. Bad connection or broken cable.

e. The motor is overheated and the thermal protection

has switched it off. When cooled the motor will turn on

automatically. Go to section .

f. The compressor has not been unloaded and there

is back pressure on the piston. Ensure that the

compressor is unloaded each time it stops.

g. The motor is blocked.

h. Defective capacitor.

2. The compressor makes a buzzing sound but does not start

a. Leaky non-return valve. Dismount the pressure pipe and

check if air leaks from the non-return valve. Clean and

replace.

b. The motor is blocked.

3. The compressor runs but the pressure does not increase

a. Intake filter clogged. Replace.

b. Non-return valve is clocked. Clean or replace.

c. Leaks in fittings, tubes or pneumatic equipment. Check

with soapy water or by letting unit stay over night

disconnected from mains. Pressure drop should not

exceed bar.

d. Check the piston gaskets. Replace if necessary.

e. Defective valve plate. Contact your JUN-AIR distributor.

4. The motor gets very hot

a. The ambient temperature is too high. If the motor is

installed in a cabinet sufficient ventilation must be

ensured.

b. Leaks in fittings, tubes or pneumatic equipment. Check

with soapy water or by letting unit stay over night

disconnected from mains. Pressure drop should not

exceed bar.

c. The compressor is overloaded.

5. The compressor runs even if no air is tapped

a. Leaks in fittings, tubes or pneumatic equipment. Check

with soapy water or by letting unit stay over night

disconnected from mains. Pressure drop should not

exceed bar.

6. The compressor does not start at min pressure or does not

stop at max pressure.

a. Defective pressure switch. Replace.

PRESSURE VESSEL

Pressure tested at I4-25 litre 24 bar

4-50 litre 18.3 bar

Directions for use

Application Receiver for compressed air

Receiver specifications See name plate

Installation Tubes, etc. must be installed with

suitable materials

Placement

Observe the working temperature of

the receiver

Ensure sufficient room for inspec-

tion and maintenance

The receiver must be kept in a hori-

zontal position

Corrosion protection

The surface treatment must be

maintained as required

Internal inspection at least every

five years

Drain condensate at least once a

week

Alternation/repair No welding must be made on pres-

surized parts

Safety valve

Ensures that PS will not be ex-

ceeded

Never adjust to a higher pressure

than PS

The capacity of the valve must be

calculated in accordance with teh

volume of air supplied by the com-

pressor

PS - Maximum working pressure of

the receiver

8

6190760 (Rev A) 120R Basic Compressor User Guide

© 2022 JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

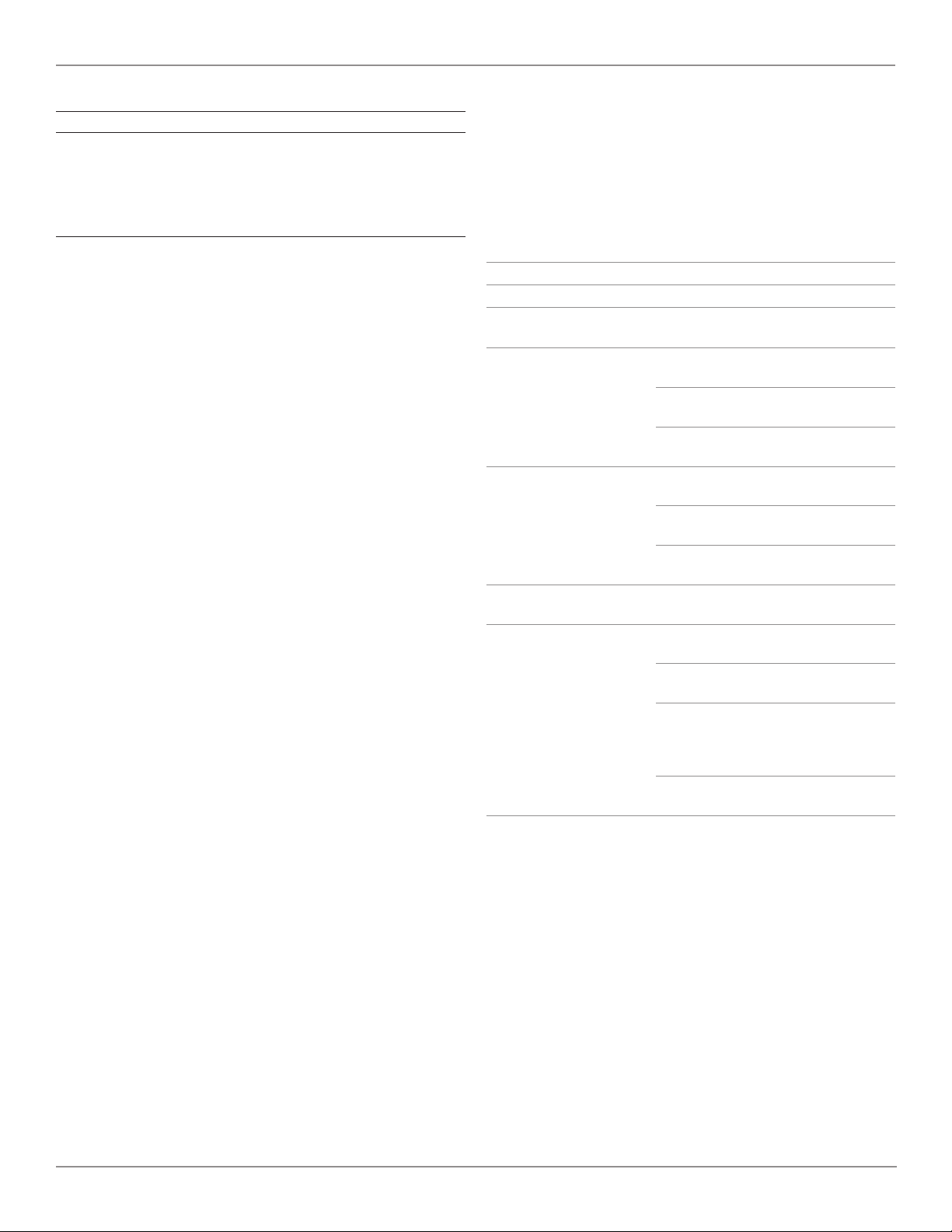

Technical Data & Specifications

Specifications 120R-40B 120R-40BQ3 2x120R-90BQ6

Tank size liter 40 40 90

U.S. gallon 10.6 10.6 24

Weight kg 55 66 102

lbs 120 144 225

Dimensions

(LxWxH)****

mm 556 x 443 x 678 556 x 581 x 678 1026 x 592 x 890

in 21.9 x 17.4 x 26.7 21.9 x 22.9 x 26.7 40.4 x 23.3 x 35.0

Pumping time @ 50 Hz 85 sec. 110 sec. 124 sec.

@ 60 Hz 72 sec. 95 sec. 107 sec.

Noise level @ 1 m @ 50 Hz 76 dB(a) 76 dB(a) 79 dB(a)

@ 60 Hz 79 dB(a) 79 dB(a) 82 dB(a)

**** Three-phase units are appoximately 100 mm wider than one-phase units.

Technical modifications reserved.

9

© 2022, JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

120 Basic Compressor User Guide 6190760 (Rev A)

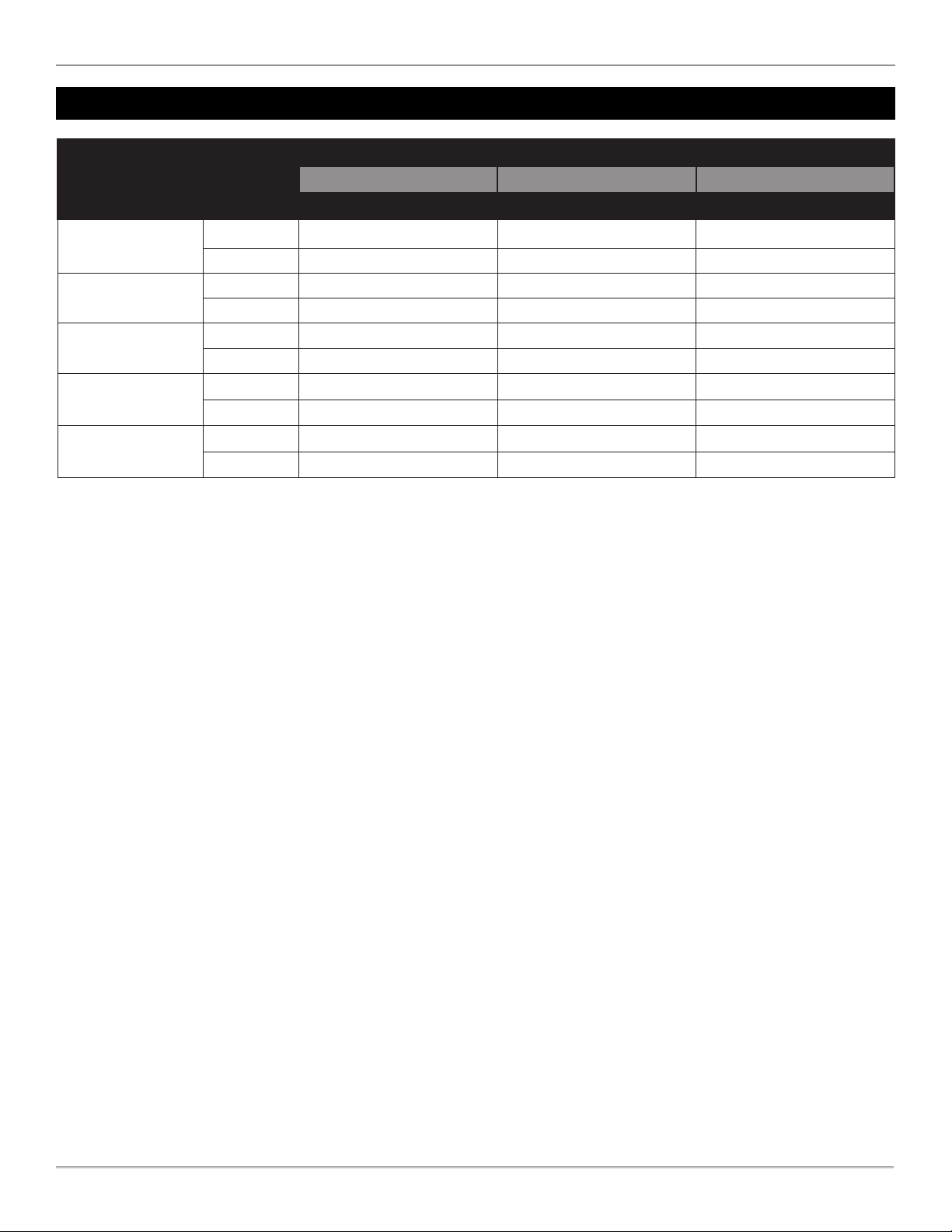

Performance Curves

10

6190760 (Rev A) 120R Basic Compressor User Guide

© 2022 JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

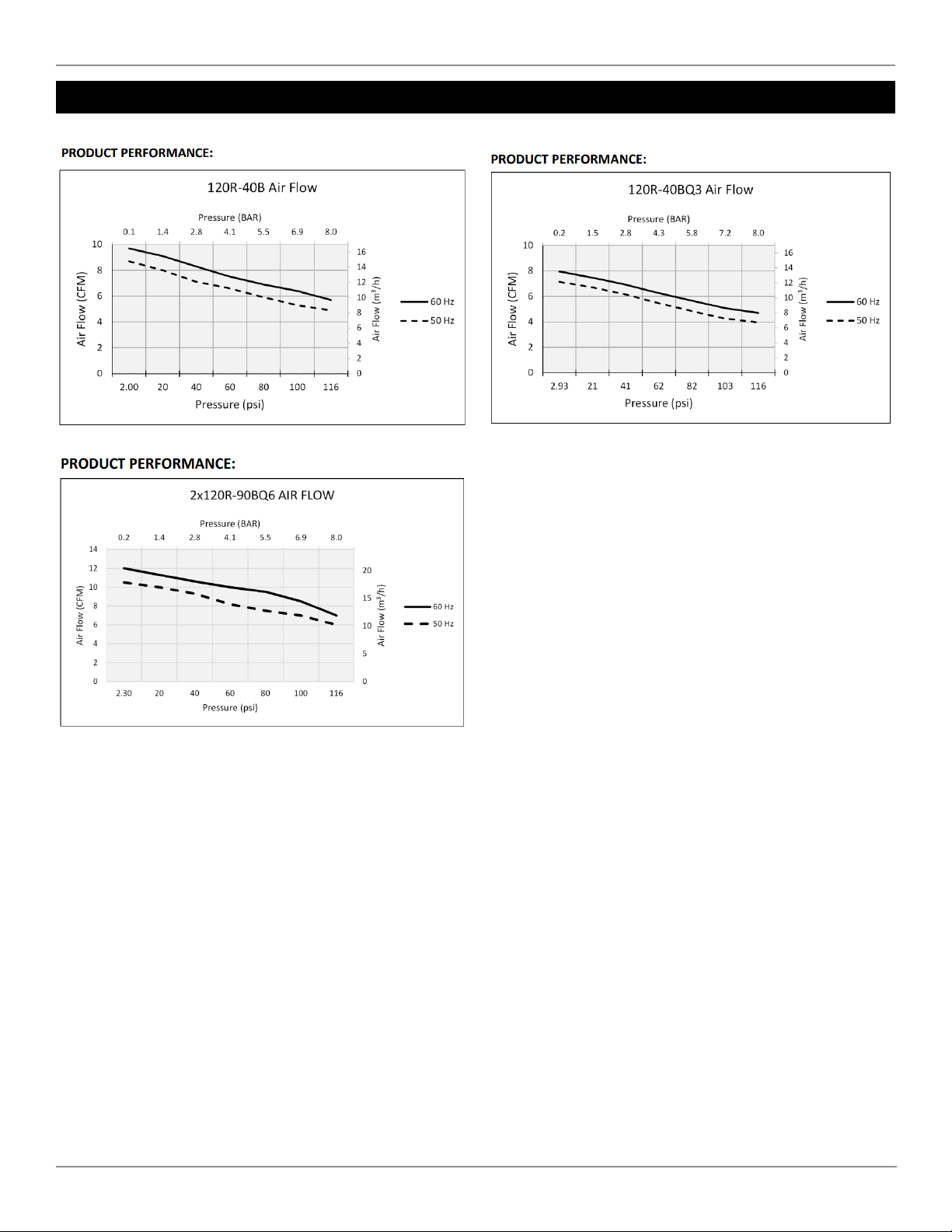

Electrical Drawing Model R-B – V, / Hz

Motor Spec.

120R, 230 V~50 Hz – 8 A

120R, 230 V`60 Hz – 10 A

11

© 2022, JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

120 Basic Compressor User Guide 6190760 (Rev A)

Electrical Drawing Model R-BQ

Motor Spec.

120R, 230 V~50 Hz – 8 A

120R, 230 V`60 Hz – 10 A

12

6190760 (Rev A) 120R Basic Compressor User Guide

© 2022 JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

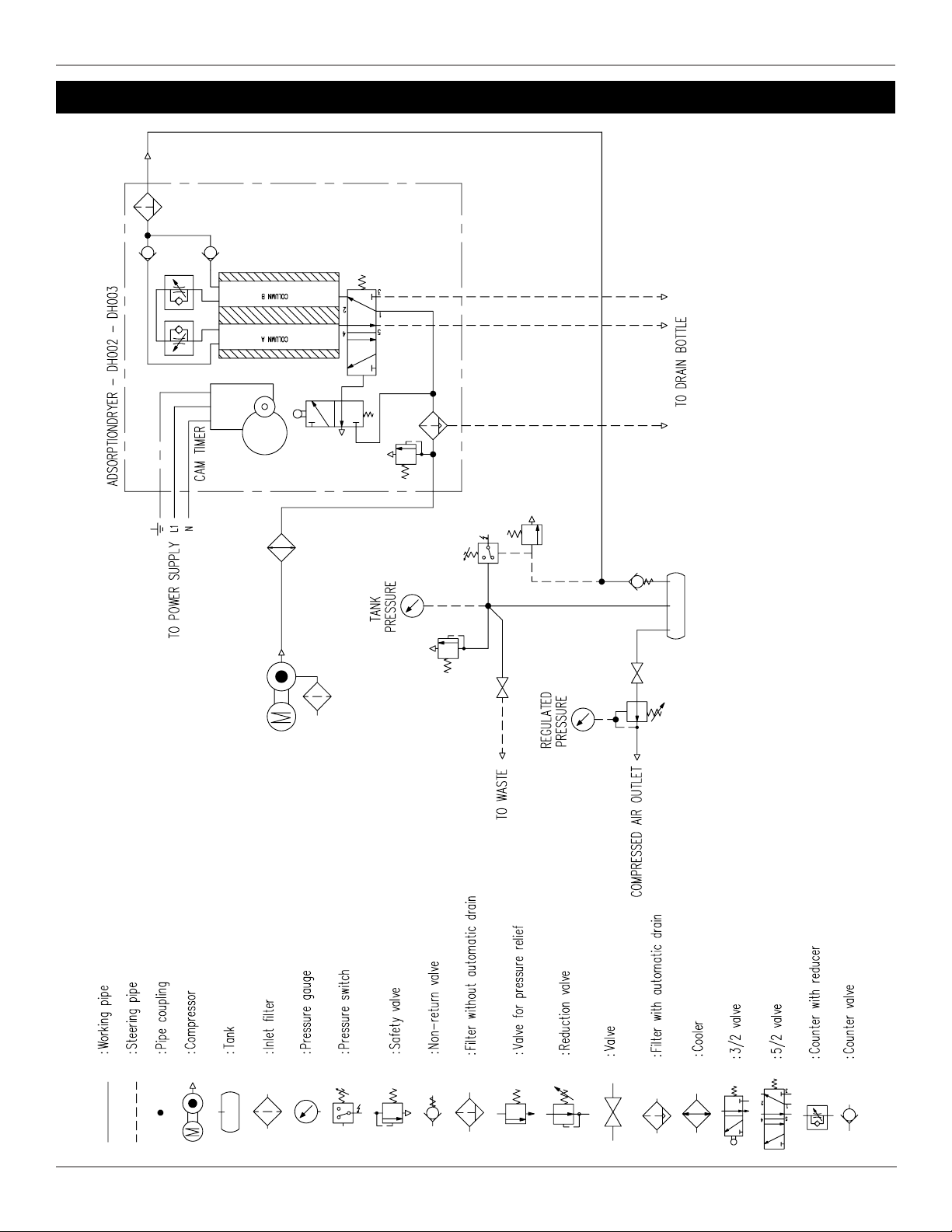

Pneumatic Diagram Model R-B

13

© 2022, JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

120 Basic Compressor User Guide 6190760 (Rev A)

Pneumatic Diagram Model R-BQ

14

6190760 (Rev A) 120R Basic Compressor User Guide

© 2022 JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

Pneumatic Diagram Model R-BQ

15

© 2022, JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

120 Basic Compressor User Guide 6190760 (Rev A)

Compressor system

R-

PM-

NNX

Compressor, V, /Hz

Receiver l horizontal CE/ASME

Receiver l silver w/inspection plug internally coated CE/ASME

Receiver l w/inspection plug, CE, silver and internally coated

Regulator R--RNMG, bar

Filter regulator um w/manual drain

Dryer f/xOF-BD/OF-BD - OX - bar

Dryer f/xOF-BD/OF-BD - OX - bar

Dryer /xOF - OX - bar

Rapid fitting Ø mm x Ø mm elbow

Box for motor protector M

Contact . kW V/V

Thermo relay .-.A Danfoss

Box for motor protection -

Connector .Q yellow/green

Connector .Q grey

Plate f/connector

Cage clamp connector

Pressure switch MDR / -way compl.

Pressure switch MDR / w/unloader

Pressure switch MDR / w/unloader

Pressure switch MDR / -way UL

Gauge Ø - bar /” down

Non return valve

Safety valve bar / psi

Safety valve bar / psi

Safety valve bar / psi

Drain cock /” l

Drain cock /” l (new)

Drain cock /” no tube

Outlet cock /”

Safety valve TÜV bar

Safety valve TÜV . bar

Connecting piece /”

Radiator & fan MOF w/camtimer V CE/UL

Randiator & fan xOF-BD with camtimer V

Radiator & fan xOF-BD without camtimer V CE/UL

Drain bottle l multi excl. accessories

Spring f/non return valve

O-ring f/” plug - x mm

O-ring Ø.x. mm

O-ring Ø.x. mm brown f/non-return valve

O-ring f/plug Ø.x. f/OF

O-ring Øx f/ /” plug

O-ring f/” plug

Rubber base Ø

Rubber base complete f/- models

Vibration damper OF

Nut Mx. brass

Screw jointM UL/CSA

Grommet black / mm

Cable grommet black Øxxmm

Cable grommet black Øxxmm

Cable grommet black Ø//xmm

Nut M DIN-

Unbraco plug /”

Washer Ø.xØx. FZB

Flex hose /” () cm

Flex hose /” () cm

Teflon hose /” cm

Teflon hose /” cm

Teflon hose /” cm

Teflon hose /” cm

Teflon hose /” cm with elbow

Teflon hose /” cm with elbow

Teflon hose /” cm with elbow

Teflon hose /” cm with elbow

Unloader complete cm with noise reduction

Unloader valve w/. mm needle

Unloader valve w/silencer OF

Silencer f/unloader valve OF

Double nipple /” L= mm

Double nipple /” w/o-ring track

Double nipple /” L= mm

Connection piece f/non-return valve model

T-piece /”

T-piece /” (xinternal/external)

T-piece Condor

Extension piece f/cock long

Extension piece w/through /”

Plug ” f/inspection

Plug /” f/inspection ASME

Plug ” galvanized

Miscellaneous

Compressor Motor

Capacitor, uF

K Preventative Maintenance Kit

K Service Kit

K Spare Parts Kit

Parts & Accessories List

16

6190760 (Rev A) 120R Basic Compressor User Guide

© 2022 JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

Spare Parts: OF-B

A

A-A

6457065

B-B

645708

0

8111930

3512150

6317000

6253200

5240612

6359000

6317000

120R689-T102-N800NX

6295830

5075010

5427000

7565000

7071000

5414500

5960000

7540000

6357100

6341800

5421004

5140000

7565000

7071601

542400

0

5427001

5427002

5427003

5130000

4071020

5416100

7024000

5424630

7167201

7167201

7024000

7566200

17

© 2022, JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

120 Basic Compressor User Guide 6190760 (Rev A)

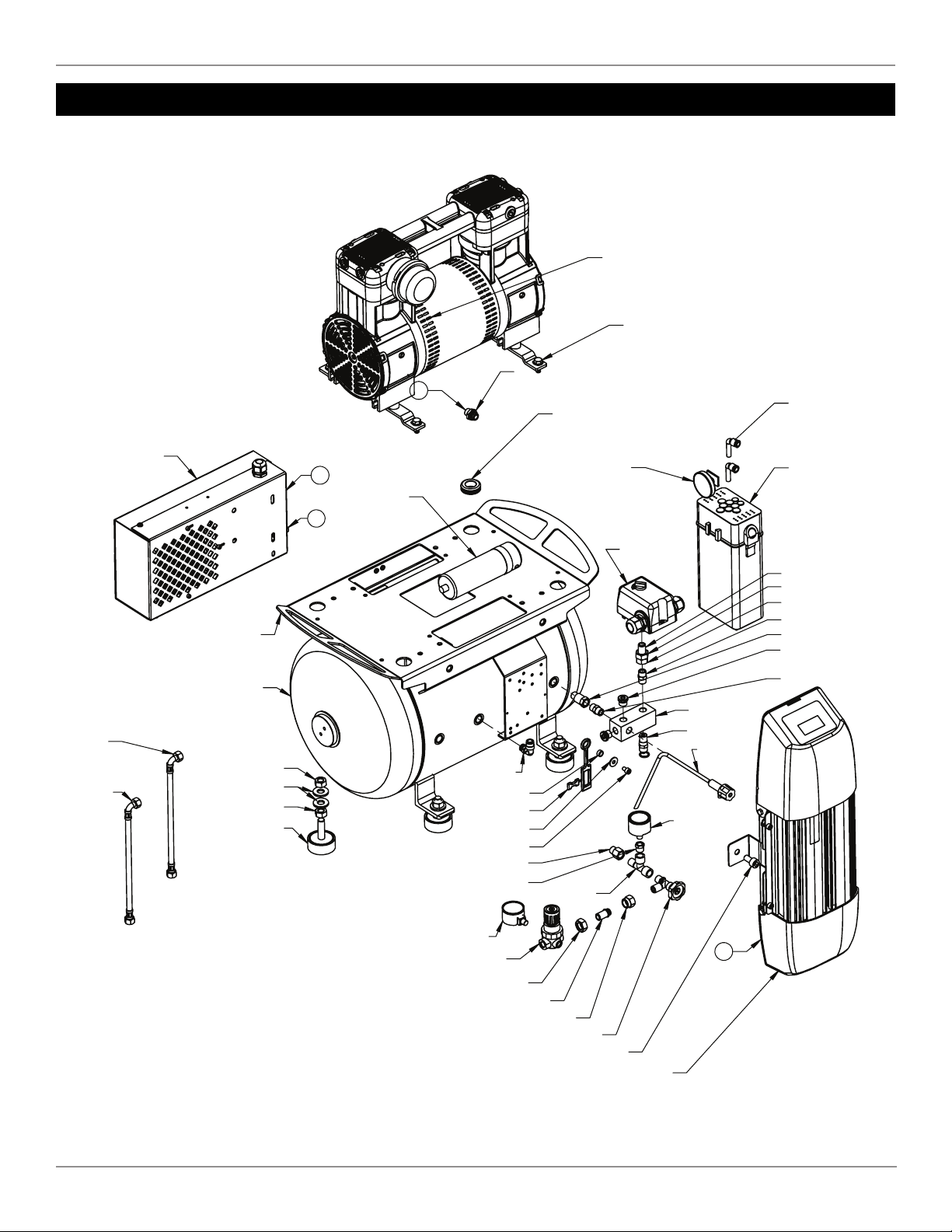

Spare Parts: R-BQ

7024002

O-RING - 6243710

A

5445235

COMPLETE

A-A

645706

5

B-B

645708

0

8111930

3512150

6317000

6253200

5240612

4094150

COMPLETE

5075011

5427003

7024000

7566200

7167201

O-RING 6243710

7024000

5424630

5416100

5421004

4146200

7540000

5960000

6357100

6341800

5140000

7566000

7565000 7071601

5130000

4071020

5427003

5427002

5427001

5424000

6344501

B

A

B

6359000

6317000

5427001

5427002

120R689-T102-N800NX

6342250

6295830

4785900

4146458

5615003

18

6190760 (Rev A) 120R Basic Compressor User Guide

© 2022 JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

Spare Parts: xR-BQ

A

B

C

D

E

F

G

H

120R689-T102-N800N

X

6342250

4521146

6314200

8110747

8111902

5612328

7565000

5414500

7071500

5445241

6357100

6341800

6357100

6341800

4094212

6355500

6343100

6343100

6355500

8111937

5445240

7180000

3936267

G

D

HOSE FROM PS SIDE MOTOR TO FAN/RADIATOR BOX W/UNLOADER VALVE

BRAIDED HOSE CONNECTING FAN/RADIATOR BOXES

B

E

CABLE FROM PRESSURE SWITCH TO DRYER

NON-RETURN VALVES W/T-FITTING CONNECTING 1 HOSE FROM EACH MOTOR

CABLE FROM DRYER TO FAN/RADIATOR BOX W/UNLOADER VALVE

CABLES FROM MOTOR(S) TO CAPACITOR(S) & TERMINAL BOX

C

LETTER

F

A

BRAIDED HOSE TO DRYER

CABLE FROM TERMINAL BOX TO DRYER

H

ATTACHMENT OR PASS THRU LOCATION

Gast Manufacturing

2300 M139 Highway

Benton Harbor, MI 49023

Ph: 269-926-6171

Fax: 269-927-0808

www.JUN-AIR.com

Gast Group Ltd.

Unit 11, The I O Centre

Nash Road

Redditch, B98 7AS

United Kingdom

Phone +44 (0)1527-504040

Fax +44 (0)1527-525262

® Registered Trademark/™ Trademark of JUN-AIR Inc. ©Copyright 2022 JUN-AIR Manufacturing Inc. All Rights Reserved.

WWW

.

JUN

-

AIR

.

COM

ISO 9001 CERTIFIED

A BRAND OF

®

This manual suits for next models

2

Table of contents

Other Gast Air Compressor manuals

Popular Air Compressor manuals by other brands

Campbell Hausfeld

Campbell Hausfeld HL540200 Operating instructions and parts manual

Boge

Boge EO Series operating instructions

Powerex

Powerex SBBSS030020SD09 operating & maintenance manual

WilTec

WilTec AS196A instruction manual

Urrea

Urrea COMP9303 User's Manual and Warrantly

Prematic

Prematic AIRSTAR 45 Original instructions