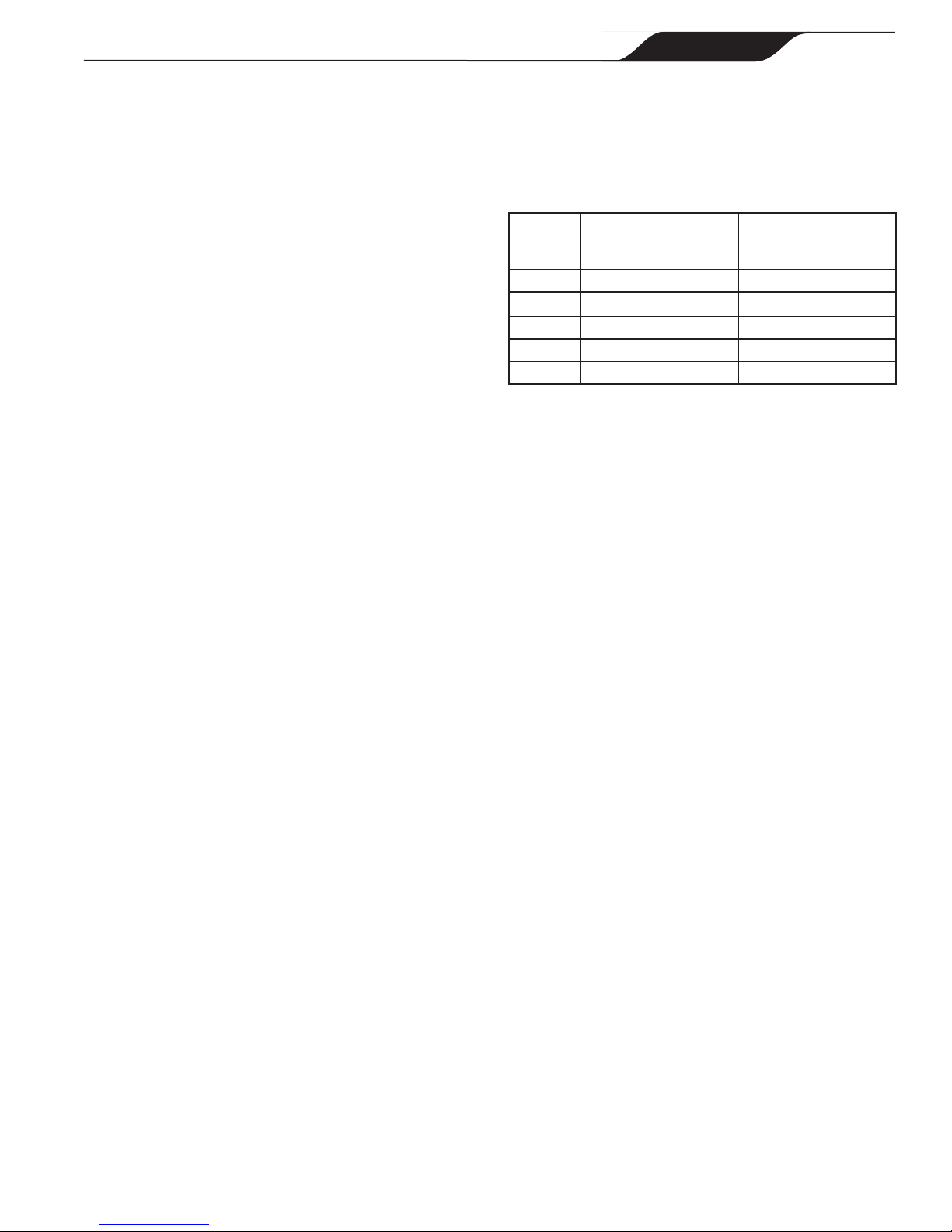

For installations of equipment up to 100 feet (30

m) from the water, refer to Table 1, the pipe sizing

chart. For installations of equipment more than

100 feet (30 m) from the water, the recommended

pipe size must be increased to the next size.

1½" 37GPM(140LPM) 50GPM(189LPM)

2" 62GPM(235LPM) 85GPM(322LPM)

2½" 88GPM(333LPM) 120GPM(454LPM)

3" 136GPM(515LPM) 184GPM(697LPM)

4" 234GPM(886LPM) 313GPM(1185LPM)

3. VS-FHP Pumps come equipped with unions on

both the suction and discharge ports. This feature

simplifies installation and service and eliminates

the possibility of leaks at threaded adapters.

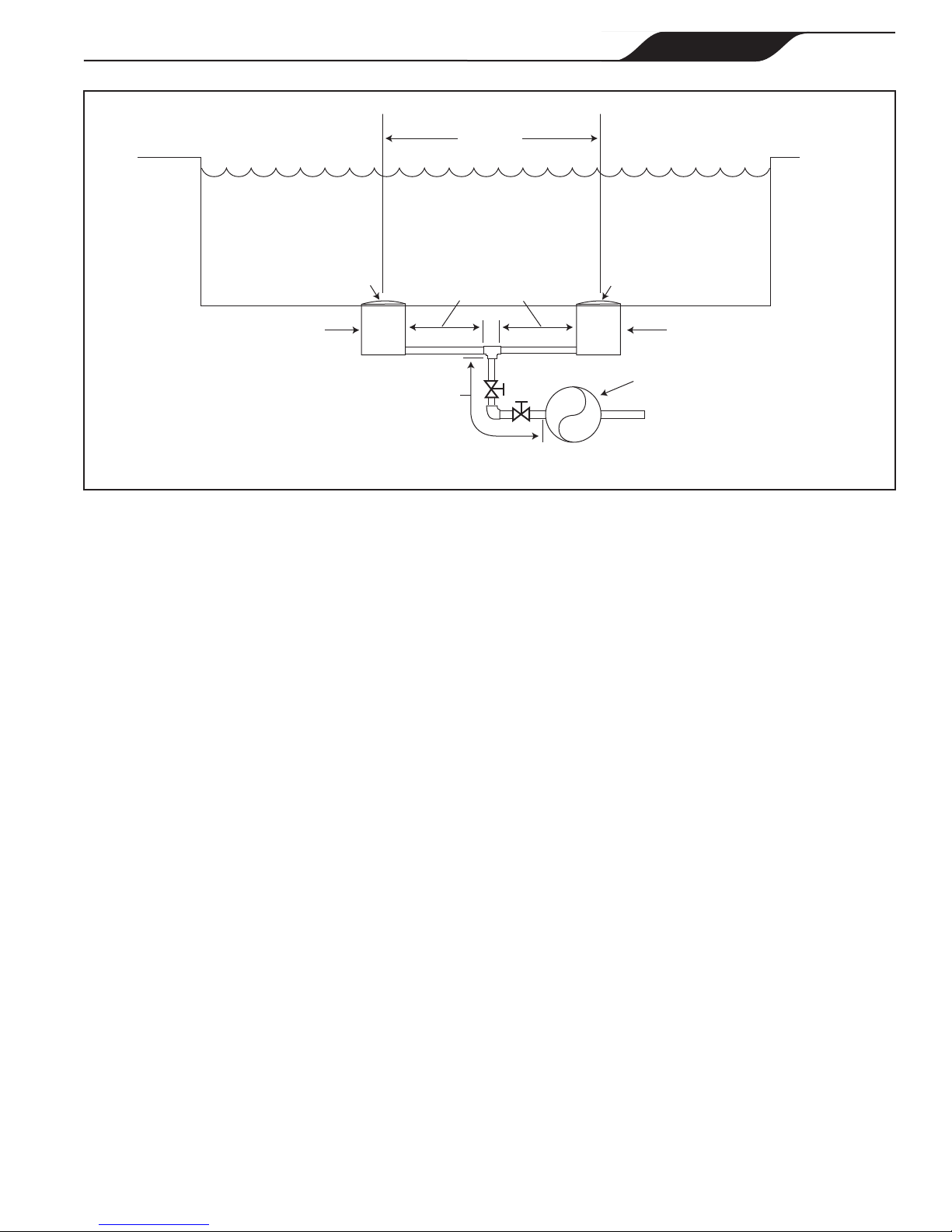

4. The VS-FHP Pump must be connected to at least

two (2) hydraulically-balanced main drains for

each pool pump suction line. Each drain must be

provided with covers that are listed or certified

to the latest published edition of ANSI/ASME

A112.19.8. The suction fittings of the main drains

must be at least three (3) feet (1 m) apart or at

different planes. The suction fittings can be a drain

and skimmer, two (2) drains, two (2) skimmers, or

a skimmer with an equalizer line installed. Check

the local codes for proper installation.

Toprevententrapment,thesystemmustbe

builtsoitcannotoperatewiththepumpdrawing

waterfromonlyone(1)maindrain.Atleasttwo

(2)maindrainsmustbeconnectedtothepump

whenitisinoperation.However,iftwo(2)main

drainsrunintoasinglesuctionline,thesingle

suctionlinemaybeequippedwithavalvethat

willshutoffbothmaindrainsfromthepump.

5. The piping must be well supported and not forced

together where it will experience constant stress.

6. Always use properly sized valves. Jandy Diverter

Valves and Jandy Ball Valves typically have the

best flow capabilities.

7. Use the fewest fittings possible. Each additional

fitting has the effect of moving the equipment

farther away from the water.

Ifmorethanten(10)suctionfittingsareneeded,

thepipesizemustbeincreased.

8. Every new installation must be pressure tested

according to local codes.

3. The pump and other circulation equipment must

be located more than five (5) feet from the water.

Choose a location that will minimize turns in the

piping.

InCanada,thepumpmustbelocateda

minimumofthree(3)meters(approximately10

feet)fromthewater(CSAC22.1).

4. The pump must be placed on a solid foundation

that will not vibrate. To further reduce the

possibility of vibration noise, bolt the pump to the

foundation, or place it on a rubber mat.

ZodiacPoolSystems,Inc.recommendsbolting

thepumpdirectlytothefoundation.

5. The pump foundation must have adequate drainage

to prevent the motor from getting wet. Protect the

pump from the rain and sun.

6. Proper ventilation is required for the pump to

operate normally. All motors generate heat that

must be removed by providing proper ventilation.

7. Provide access for future services by leaving a

clear area around the pump. Allow plenty of space

above the pump to remove the lid and basket for

cleaning.

8. If the equipment is in a potentially dark area,

provide adequate lighting.

When the pump is located up to 50 feet (15 m) from

the pool, the recommended minimum pipe size for the

suction side of the pump is two (2) inches (5 cm). For

suction lengths greater than 50 feet see Section 3.1.3.3

Step 2.

When the pump is located up to 50 feet (15 m) from

the pool, the recommended minimum pipe size for the

discharge side of the pump is two (2) inches (5 cm).

For discharge lengths greater than 50 feet (15 m) see

Section 3.1.3.3 Step 2.

1. If the pump is located below water level, isolation

valves must be installed on both sides of the pump

to prevent the back flow of pool water during any

routine or required servicing.

2. To help prevent difficulty in priming, install the

suction pipe without high points (above inlet of

pump - inverted “U”s, commonly referred to in

plumbing as an airlock) that can trap air.

Page 9

Jandy® FloPro™ Variable-Speed Pump Series VS-FHP | Installation and Operation Manual ENGLISH