A-2

GENERAL

INFORMATION

and

symbols

and

words help guide you through each

step...

0

<S>

© ® 0

CHECK

CONNECT

DISCONNECT

REPAIR

OR

REPLACE

80371C

The

charts

are

divided into

three

sections:

step,

se

quence

and

result.

Always

start

at

the first step and go

through

the

complete sequence from left to right.

80371o

Asequence could be checking pressure in all tires

and

inflating to specified pressures. If

the

problem is solved,

the

symbol

@

will

send

you

to

@ .

If

the

prob

lem

is

not

solved,

the

symbol

@)

will

send

you

through

another

sequence of checks which ends with a

result

and

tells you

the

next

step

to go to.

Work through

eachstep

of the DARS

charts

until the

system

is

repaired

Service

Diagnosis

Charts

You will also find Service Diagnosis

Charts

through

out

this

manual.

These

charts

list causes

of

specific

problems in descending order of probability.

It

is more

likely

that

aproblem would

result

from

the

first

listed

"possible cause"

than

the

fourth, for instance.

Visual inspection often leads directly to

the

correct

solution. All service procedures should begin

with

a

careful visual inspection of

any

suspected

part

or

assembly.

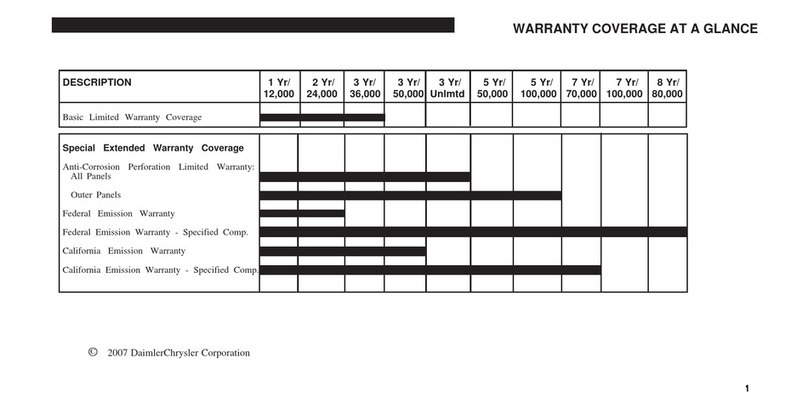

Torque

Information

Individual torque charts appear

at

the end of each

chapter. Torque values are expressed two ways, Set-To

and

In-Use

Recheck.

The

Set-To

value

is

used

when

assembling components. The In-Use Recheck value is

used to check pretightened items.

Refer to

the

Standard

Torque Specifications

and

Cap-

screw Markings

Chart

in this

chapter

for

torques not

listed in individual torque charts. Note

that

torque

spec

ifications given in the chart are based on use of clean

and dry threads. Reduce torque by 10 percent when

threads

are

lubricated with engine oil

and

by 20

percent

if new plated capscrews

are

used.

Standard

Torque

Specifications

and

Capscrew

Markings Chart

CAPSCREW

HEAD

MARKINGS

CAPSCREW

BODY

SIZE

Inches

—

Thread

SAE

GRADE

1

or

2

(Used

Infrequently)

SAE

GRADE

5

(Used

Frequently)

SAE

GRADE

6

or

7

(Used

at

Times)

SAE

GRAOE

8

(Used

Frequently)

Torque Torque

Torque

Torque

Ft-Lb

Nm

Ft-Lb

Nm

Ft-Lb

Nm

Ft-Lb

Nm

Manufacturer's

marks

may

vary.

The—

Una

markings

on

heads

shown

below,

tor

example,

indi

cate

SAE

Grade

5.

SAE

lor

2

SAE

5

1/4-20

-28

5

6

6.7791

8.1349

8

10

10.8465

13.5582

10

13.5582

12

14

16.2698

18.9815

5/16-18

-24

11

13

14.9140

17.6256

17

19

23

0489

25.7605

19

25.7605

24

27

32.5396

36

6071

3/8-16

-24

18

20

24.4047

27.1164

31

35

42.0304

47.4536

34

46.0978

44

49

59.6560

66.4351

7/16-14

-20

28

30

37.9629

40.6745

49

55

66.4351

74.5700

55

74.5700

70

78

943073

105.7538

1/2-13

-20

39

41

52.8769

55.5885

75

85

101.6863

115.2445

85

115.2445

105

120

142.3609

162.6960

9/16-12

-18

51

55

69.1467

74.5700

110

120

149.1380

162.6960

120

162.6960

155

170

210.1490

230.4860

5/8-11

-18

83

95

112.5329

128.8027

150

170

203.3700

230.4860

167

226.4186

210

240

284.7180

32S.3920

3/4-10

-16

105

115

142.3609

155.9170

270

295

366.0660

399.9610

280

379.6240

375

420

508.4250

569.4360

7/8-

9

-14

160

175

216.9280

237.2650

395

435

535.5410

589.7730

440

596.5520

605

675

820.2590

915.1650

SAE

8

or

7

8AE8

1-

8

-14

235

250

318.6130

338.9500

590

660

799.9220

894.8280

660

894.8280

910

990

1233.7780

1342.2420

70090