Installation, Operating and Maintenance Instructions, Warranty

Certificate, Operating Principle

✓Jenesis Steam Generators are delivered with one operating instructions folder.

✓The folder contains the installation instructions, the general operating and maintenance instructions for

the steam generator, the operating instructions for all parts used on the steam generator (burner, pump,

etc.) and the warranty documents.

4

✓Steam Generators are water pipe steam generators that produce fast steam due to the small volume of

water in them and that do not have a risk of exploding. They are very sensitive to the water used. The

water to be used must be well filtered and free of limescale ions.

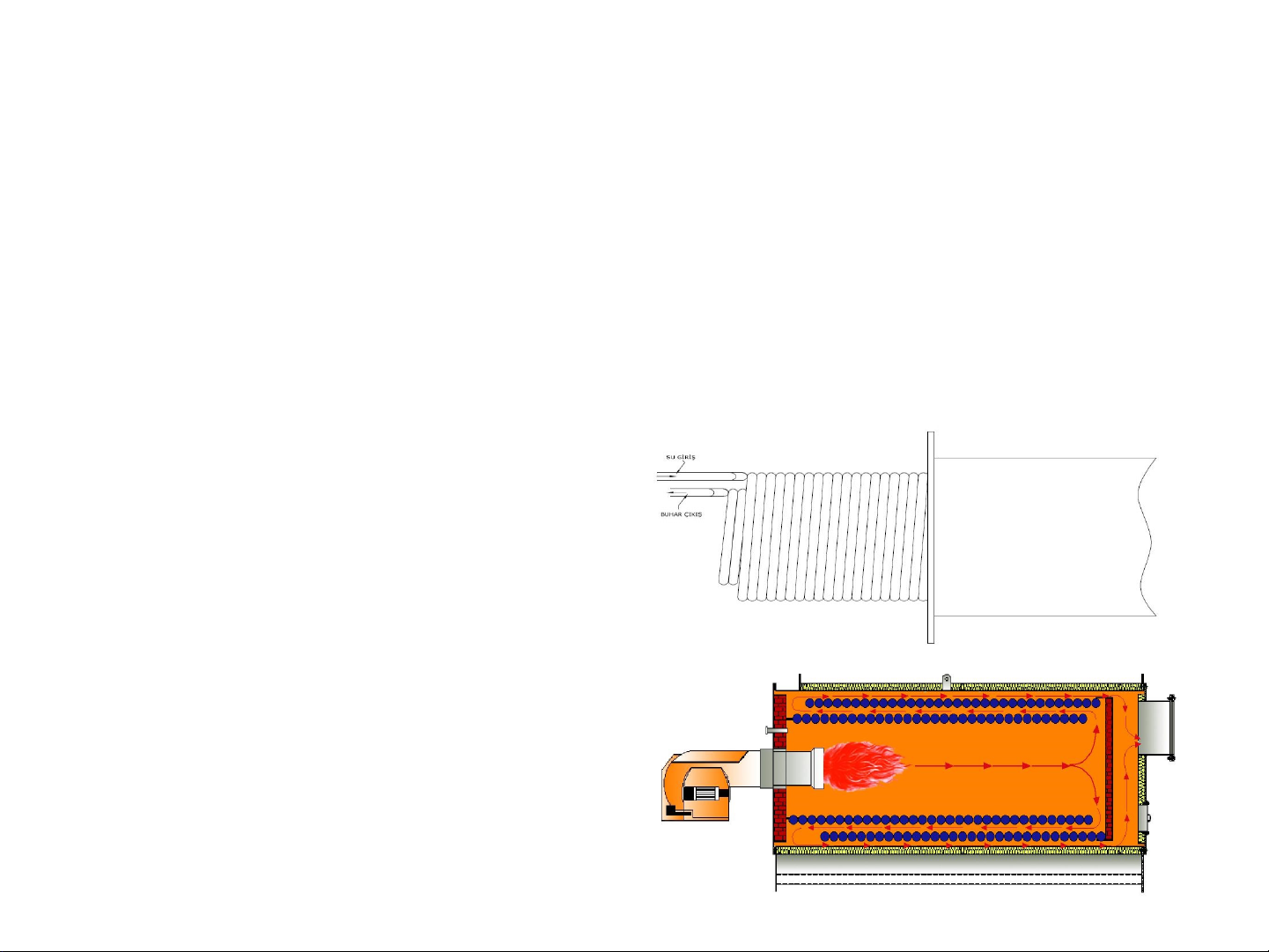

✓Steam generator consists of the main body (smoke channel), coil(serpentine)e (pressure hull), burner,

electric control panel, feed water pump, separator, condensate tank and smokestack sections.

✓As seen in the picture, the “coil(serpentine)”

consists of two intertwined spirals. The inlet and

outlet ports of the spiral are shown on the front

cover.

✓When installing the steam generator, a space equal

to the size of the device must be left on the front

side, in case of removal of the “coil(serpentine)”.

Otherwise, the steam generator “coil(serpentine)”

cannot be removed.

✓The water that is purified by the water softening

device and ready to use in the condensate tank is

pressed in through the coil(serpentine)e inlet port

with feed water pumps. When the burner is

activated, the water in the coil(serpentine)e

evaporates, advances towards the outlet and

reaches the separator. Pressure and temperature

controls are made with the control devices on the

separator and the produced steam is served to the

process by opening the main steam valve.