FUEL

S

YST

EM

CARBURETOR

r

-

~=

=

___

-_

-_-_

-_-

_-_-

_-

::

_-

___

~

-.

~

_<?i

_-_

-_-_

~

~

~

-_

~~~

___

=

~

_-

_

~

=

=~

~

-:

I , I

I , '

!

i

~i

I I I

I : : :

: : I :

I t I I

I I I I

I : I I

I I I 1

I I I

Starter

:n:

plunger:

:

, :

, ,

Throttle

valve

Float

,

I I

I '

I :

, ,

Starter

jet

Fuel

..

Air

CJ

Mixture

¢ri

Jet

needle

Pilot

jet

Ring

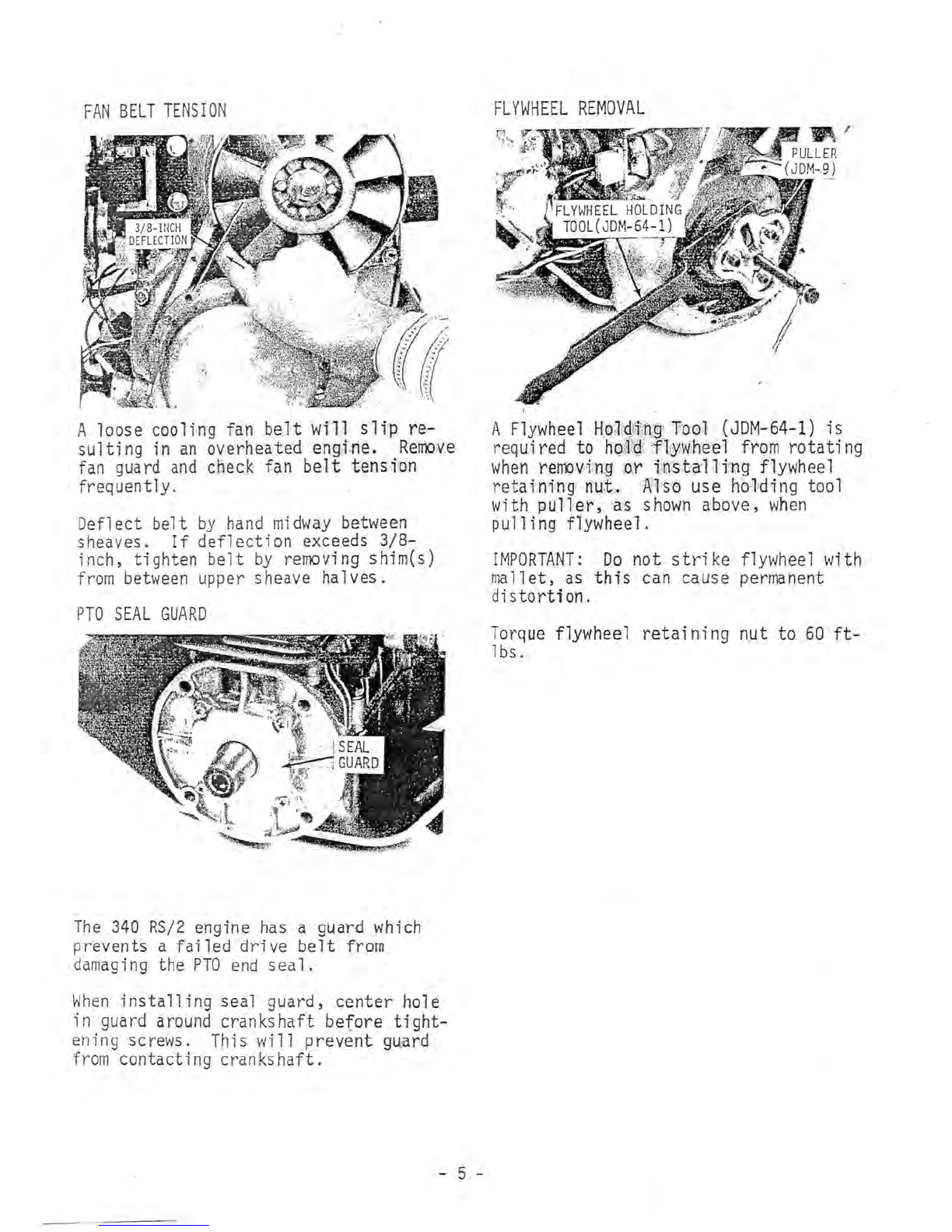

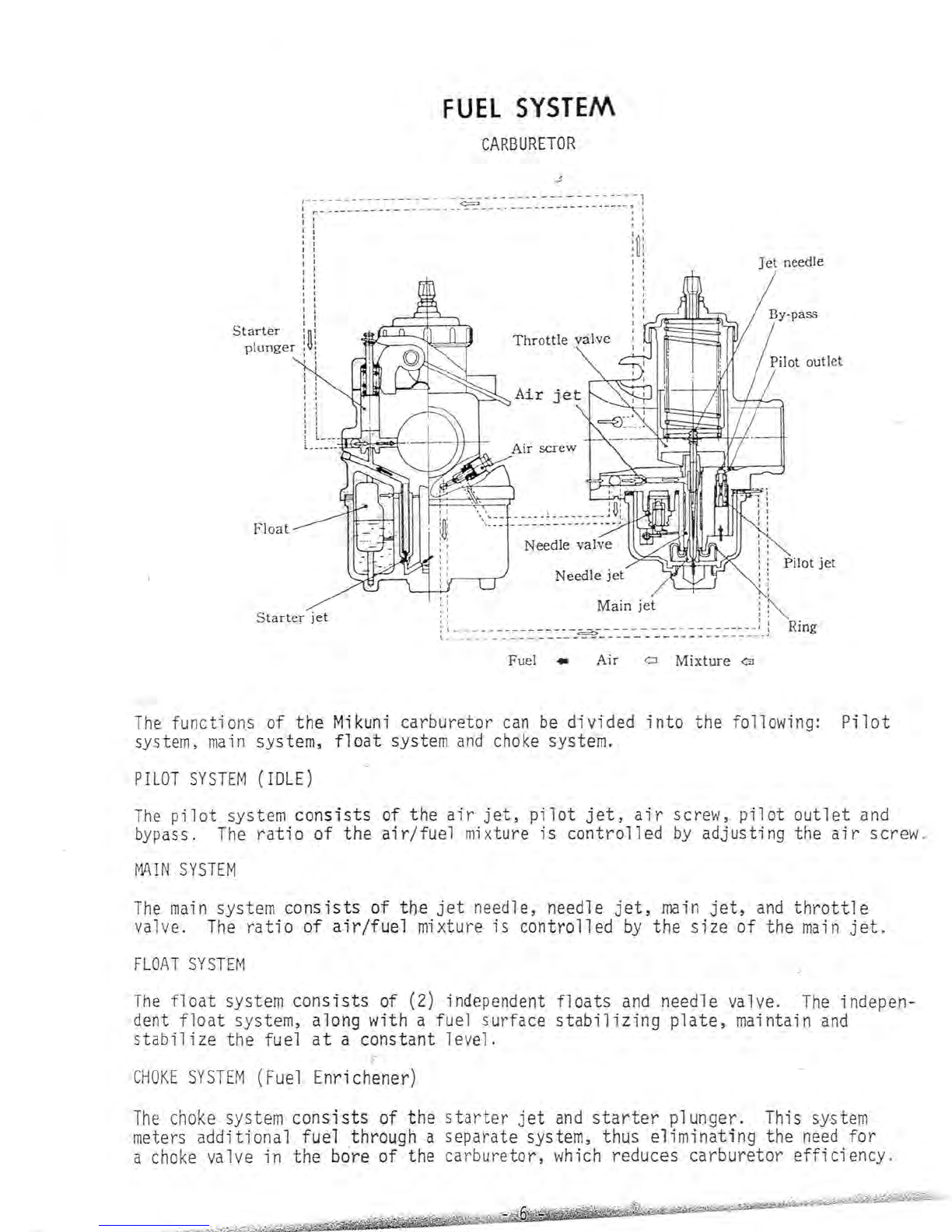

The

function,s of the

Mikuni

carburetor

can

be

divided

into

the following:

Pilot

system,

main

system,

float

system

and

choke

syste~.

PILOT

SYSTEM

(IDLE)

The

pilot

system

con

s

ists

of the

air

jet,

pilot

jet,

air

screw,

pilot

outlet

and

bypass.

The

ratio

of the

air/fuel

mixture

is

controlled

by

adj.ustingthe

air

screw.

MA.IN

SYSTEM

The

main

system

consists

of the

jet

needle, needle

jet,

main

jet,

and

throttle

valve.

The

ratio

of

air/fuel

mixture

is

controlled

by

the

size

of the

main

jet.

FLOAT

SYST

EM

The

float

system

consists

of (2) independent

floats

and

needle valve.

The

indepen-

dent

float

system, along with a fuel surface

stabilizing

plate,

maintain

and

stabilize

the fuel

at

a constant

le

v

el.

CHOKE

SYSTEM

(Fuel Enrichener)

The

choke

system

consists

of the

starter

jet

and

starter

plunger. This system

meters additional fuel through a separate system, thus

eliminating

the

need

for

a

choke

valve in the

bcire

of the carburetor,

which

reduces carburetor

efficiency.