Johnson Electric Nanomotion AB1A User manual

D/N: AB1A458000-00 REV: F December 2011

Nanomotion Ltd. POB 623, Yokneam 20692, Israel

Tel: 972-73-2498000 Fax: 972-73-2498099

Web Site: www.nanomotion.com

E-mail: nano@nanomotion.com

AB1A Driver

User Manual

Nanomotion Ltd. Page 2 of 29

Copyright

This document contains proprietary information of Nanomotion Ltd., and Nanomotion

Inc., and may not be reproduced in any form without prior written consent from

Nanomotion Ltd. and Nanomotion Inc.

No part of this document may be reproduced, translated, stored in a retrieval system or

transmitted in any form and by any means, electronic, mechanical, photographic,

photocopying, recording, or otherwise, without the written permission of Nanomotion Ltd.

Information provided in this document is subject to change without notice and does not

represent a commitment on the part of Nanomotion Ltd.

Copyright June 2001, Yokneam, Israel. All rights reserved.

All products and company names are trademarks or registered trademarks of their

respective holders.

Limited Warranty

Nanomotion Ltd. (hereinafter NM) warrants the product (other than software)

manufactured by it to be free from defects in material and workmanship for a period of

time of one year (except those parts normally considered as consumable/expendable

components such as motor conditioning brushes). The warranty commences thirty (30)

days from the date of shipment.

NM warrants those parts replaced under warranty for a period equal to the remaining

warranty coverage of the original part.

NM’s sole and exclusive obligation under this warranty provision shall be to repair, or at

its sole option exchange defective products or the relevant part or component, but only if:

(i) the Purchaser reports the defect to NM in writing and provides a description of the

defective product and complete information about the manner of its discovery within ten

(10) days of its discovery; (ii) NM has the opportunity to investigate the reported defect

and determines that the defect arises from faulty material, parts or workmanship; and (iii)

the Purchaser returns the affected product to a location designated by NM. These

provisions constitute the exclusive remedy of the Purchaser for product defects or any

other claim of liability in connection with the purchase or use of NM products.

This warranty policy applies only to NM products purchased directly from NM or from an

authorized NM distributor or representative.

This warranty shall not apply to (i) products repaired or altered by anyone other than

those authorized by NM; (ii) products subjected to negligence, accidents or damage by

circumstances beyond NM control; (iii) product subjected to improper operation or

maintenance (i.e. operation not in accordance with NM Installation Manuals and/or

instructions) or for use other than the original purpose for which the product was

designed to be used.

NM shall not in any event have obligations or liabilities to the Purchaser or any other

party for loss of profits, loss of use or incidental, increased cost of operation or delays in

operation, special or consequential damages, whether based on contract, tort (including

negligence), strict liability, or any other theory or form of action, even if NM has been

advised of the possibility thereof, arising out of or in connection with the manufacture,

sale, delivery, use, repair or performance of the NM products. Without limiting the

generality of the preceding sentence, NM shall not be liable to the Purchaser for

personal injury or property damages.

CE Compliance

Nanomotion Ltd. Page 3 of 29

CE Compliance

This product has been tested for Electric Safety and Electromagnetic

Compatibility and found to be in compliance with the following directives

and standards:

EMC Council Directive 89/336/EEC

Safety Council Directive 73/23/EEC

EN 55011:1998 + A1:1999

EN 61000-6-2:1999

EN 61010-1:1993 + A2:1995

Table of Contents

Nanomotion Ltd. Page 4 of 29

Table of Contents

1AB1A DESCRIPTION ..................................................................................................8

1.1 General ........................................................................................................................8

1.2 Main Features ..............................................................................................................8

1.3 Operating Principles.....................................................................................................9

2CONNECTIONS AND I/O SETTINGS........................................................................11

2.1 AB1A Front Panel.......................................................................................................11

Front Panel Connectors..............................................................................................112.1.1

Front Panel Indicators ................................................................................................12

2.1.2

2.2 Motion Controller/Joystick Connection........................................................................12

Differential Analog Connection ...................................................................................122.2.1

Joystick Connection....................................................................................................152.2.2

2.3 Cable Connections.....................................................................................................16

Shielding ....................................................................................................................162.3.1

2.4 Motor Connections .....................................................................................................16

Motor Cable Length....................................................................................................162.4.1

2.5 Opto-isolated Inputs ...................................................................................................17

Voltage Source Configuration.....................................................................................182.5.1

2.6 Fault Output................................................................................................................19

2.7 Before Operating the Motor........................................................................................19

3THERMAL ENVELOPE OF PERFORMANCE (EOP)................................................20

3.1 Description.................................................................................................................20

3.2 Stage Heat Dissipation Consideration ........................................................................20

3.3 Thermal EOP for HR Motor Driven by AB1A, AB2, AB4 Drivers.................................21

4AB1A OPERATION ...................................................................................................23

4.1 Operation Modes........................................................................................................23

Velocity Mode Operation ............................................................................................234.1.1

Step Mode operation..................................................................................................234.1.2

4.1.2.1Enabling the Step Mode .............................................................................................23

Gate Mode Operation.................................................................................................234.1.3

4.1.3.1Enabling the Gate Mode.............................................................................................24

4.2 Using the AB1A to Drive LS Motors............................................................................24

5SPECIFICATIONS .....................................................................................................25

5.1 Parameters and Conditions........................................................................................25

5.2 AB1A Layout ..............................................................................................................27

5.3 AB1A Pin Arrangement ..............................................................................................28

List of Abbreviations

Nanomotion Ltd. Page 5 of 29

List of Figures

Figure 1: AB1A Block Diagram .........................................................................................9

Figure 2: Schematic Diagram of the Output Stage with an Internal LC Card...................10

Figure 3: AB1A Driver Box Front Panel...........................................................................11

Figure 4: Differential Analog Input Connection................................................................13

Figure 5: Non-Differential (single-ended) Analog Input Connection.................................14

Figure 6: Joystick Connection.........................................................................................15

Figure 7: Opto-Isolated Input Interface ...........................................................................17

Figure 8: Jumper 1 Configuration....................................................................................18

Figure 1: Motor Velocity vs. Command...........................................................................21

Figure 2: Motor Force vs. Velocity at the Various Work Regimes (a-g)...........................22

Figure 9: AB1A Layout....................................................................................................27

List of Tables

Table 1: EOP Table for HR Motors Driven by AB1A, AB2, AB4......................................22

Table 1: AB1A Power Consumption................................................................................25

Table 2: Electrical Specifications ....................................................................................25

Table 3: Physical dimensions .........................................................................................25

Table 4: Environmental Conditions.................................................................................26

Table 5: Analog Input Specifications...............................................................................26

Table 6: Control Terminal Pin Out...................................................................................28

Table 7: Motor Output Port Pin Out.................................................................................28

Table 8: I/O Connector Pin Out.......................................................................................29

List of Figures

Nanomotion Ltd. Page 6 of 29

List of Abbreviations

A

Ampere

AC

Alternating Current

DC

Direct Current

LC

Coil Capacitor Resonance Circuit

LED

Light Emitting Diode

mA

Milliampere

mW

Milliwatt

TTL

Transistor-Transistor Logic

Vrms

Volts Root Mean Square

New Edition Remarks

Nanomotion Ltd. Page 7 of 29

New Edition Notes:

This edition is released to reflect the following changes:

1. New mode of operation has been added to the

driver: Gate Mode (for more details see Section

4.1.3). This new feature is available in drivers

bearing serial numbers 4800 and forward.

2. CE compliance section has been revised.

Other changes to the manual are primarily editorials, aiming to make the

manual a more user-friendly one.

AB1A Description

Nanomotion Ltd. Page 8 of 29

1AB1A Description

1.1 General

The AB1A is a single-axis Amplifier Box designed to drive up to 32 motor

elements in parallel.

The AB1A Card consists of DC/DC converters that provide the voltages

necessary to operate the amplifier circuit: +5V, ±12V, +3.3V. In addition, the

card contains two LED indicators and the external interface connectors for the

INPUT, MOTOR, and I/O signals.

The system configuration may require an LC Card that is connected either

internally to the AB1A Card, or externally in a separate LC Box. If the LC Card

connection is external, then it is required to connect an adapter card to the

AB1A. The adapter card shorts the necessary pins to enable the connection of

the external LC Card.

1.2 Main Features

High precision (11 bits) control of the power output stage

Drives up to 32 Nanomotion motor elements in parallel

Three modes of operation: Velocity Mode, Step Mode, and

Gate Mode

Interfaces with an Analog command

Discrete inputs enable feedback from external sources, such as

limit switches, emergency stop command, etc.

LED indicators

Reduced sensitivity to cable length and capacitance

Compact dimensions

AB1A Description

Nanomotion Ltd. Page 9 of 29

1.3 Operating Principles

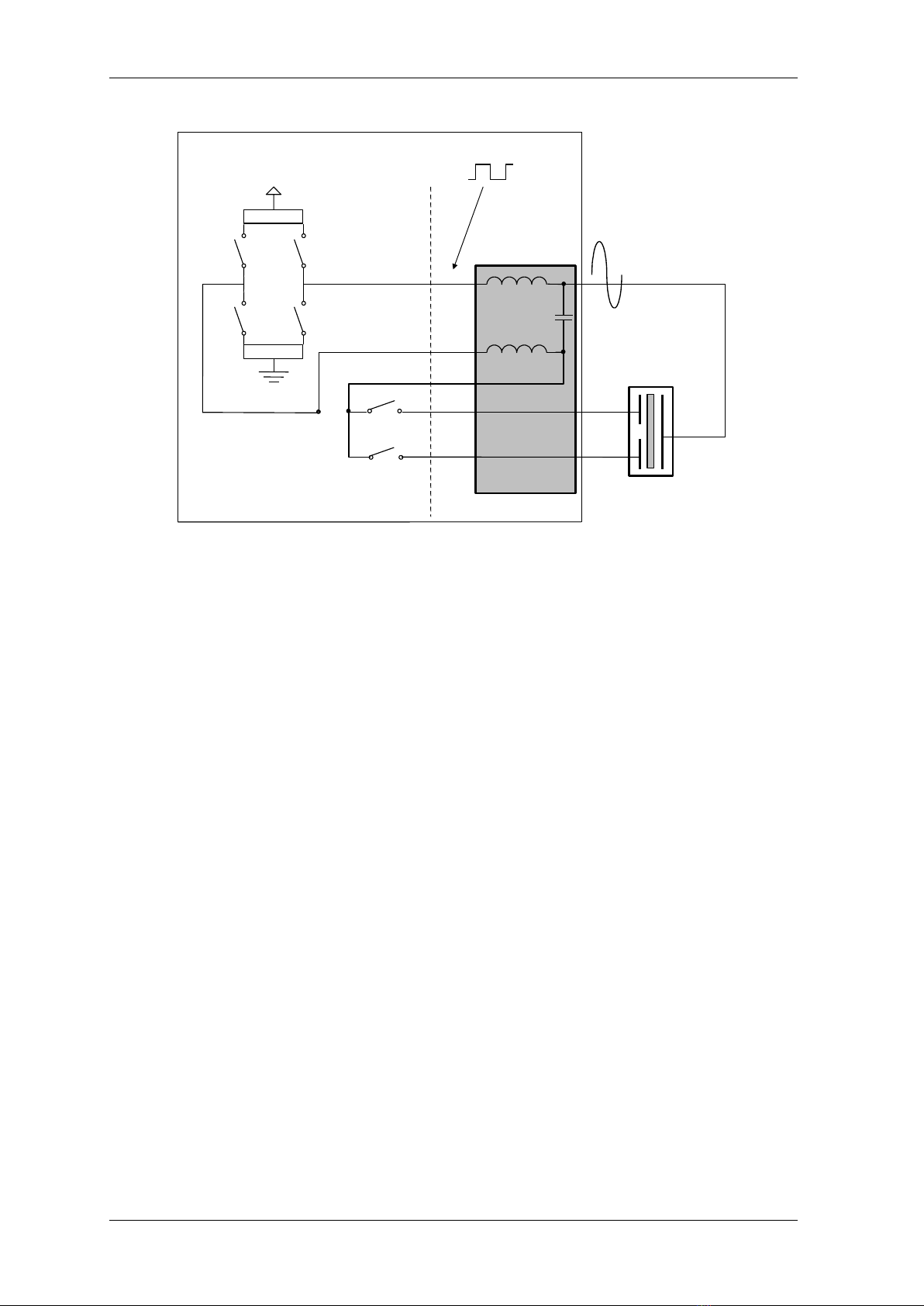

The AB1A Driver Box comprises the AB1A main card and an LC card. The

AB1A Card converts the analog input command signal into a corresponding

PWM square wave output signal that is fed to the LC Card. The LC Card

produces the sine wave output voltage that drives the motor.

The LC Card type and configuration depends on the number of motor elements

driven.

For 1 to 16 elements, the LC circuit is internal to the AB1A

For 32 elements, the LC circuit is external to the AB1A (LC

Box)

An internal DC-to-DC converter that is fed from an external +48V power supply

supplies the required DC voltages.

Figure 1 illustrates a typical application of the AB1A Driver Box.

Figure 1: AB1A Block Diagram

The motor has three terminals: “UP” (red wire), “DOWN” (white wire) and

“COMMON” (black wire). The voltage applied between the “UP” and the

“COMMON” terminals causes the motor to move in one direction, while voltage

applied between the “DOWN” and the “COMMON” terminals causes the motor

to move in the opposite direction.

Figure 2 is a schematic drawing of the power output.

Operating Principles

Nanomotion Ltd. Page 10 of 29

+48v

H-BRIDGE

DIRECTION

CONTROL

NANOMOTION

MOTOR

COMMON

UP

DOWN

"Common"

"Phase"

"Up"

"Down"

LC Card

AC output that drives

the motor

AB1A

PWM - Square wave on

the amplifier output

Figure 2: Schematic Diagram of the Output Stage with an Internal LC Card

Table of contents