B

LUBRICATION

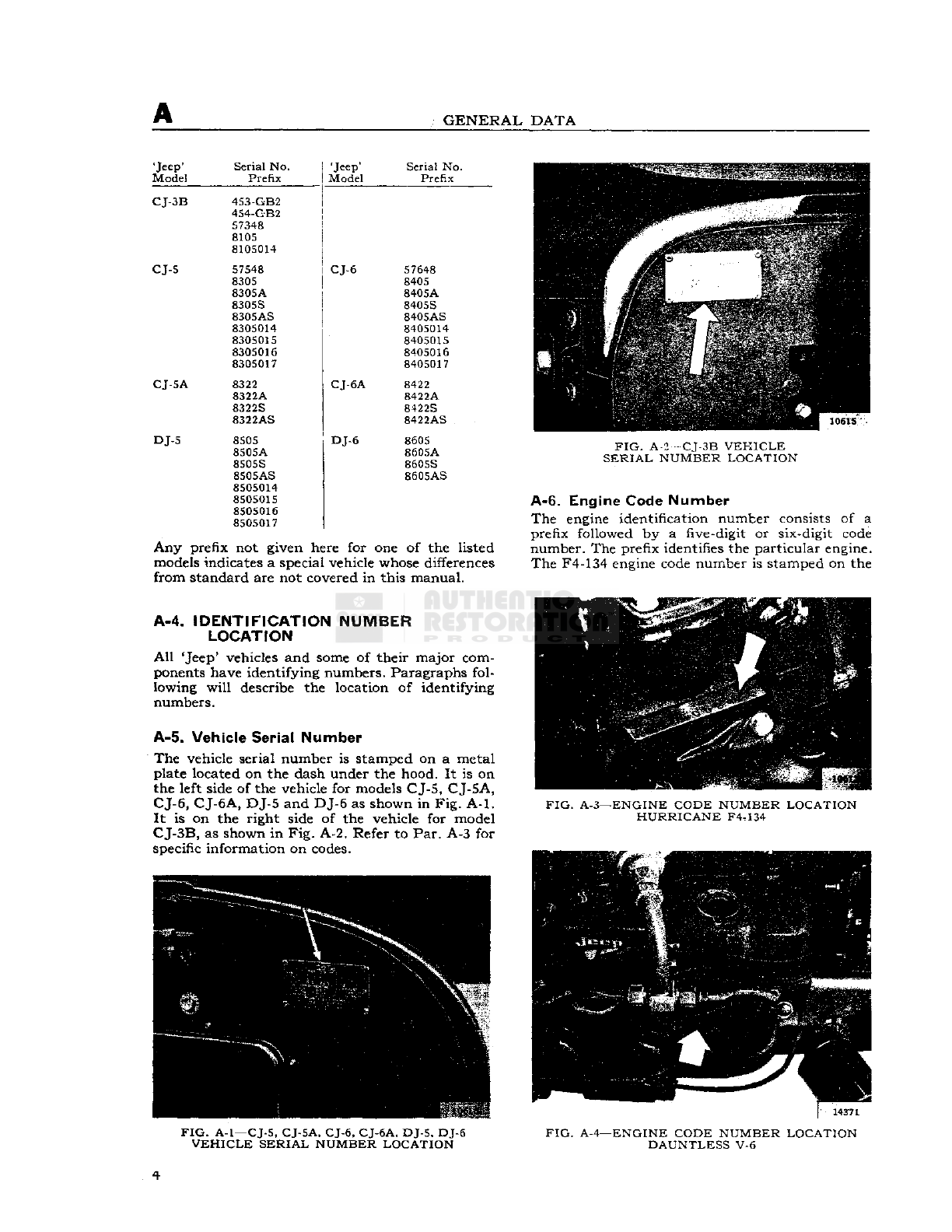

B-2.

SpecialLubricants

Special

lubricantsarerequiredforcertain

lubri-

cationpointsonthe'Jeep'Universalvehicles.The

special

lubricantsarenecessaryforproperfunction-

ingandmaintenanceofthevehicle.The

Lubrica-

tion

Chart

(Fig.B-landB-2)

designates

thespe-

cial

lubricatingpointsandidentifiesthembytype

or

partnumber.

B-3.

Applying

Fresh

Lubricant

When

servicingorlubricatingthevehicle,itis

importantthatalloldlubricantand

dirt

bere-

movedfromthefittingand/orplugsbeforeservic-

ingandthattherecommendedtypeoflubricant

beusedfortheparticularitembeingserviced.

Force

lubricantthroughthelubefittingsuntil

thelubricantbeingforcedoutofthejointisfresh

lubricant,

indicatingthatalloldlubricanthas

beenremoved.

B-4.

Engine

Lubrication

System—

Hurricane

F4Engine

•

RefertoFig.B-3.

The

engine

oilpressuresystemisdesignedtopro-

videadequatelubricationtoallworkingpartsof

theengine.Thegear-typeoilpumpisdrivenfrom

the

engine

camshaft.Thepumpisprovidedwitha

FIG.

B-3—ENGINE

LUBRICATION

SYSTEM

—

HURRICANE

F4

ENGINE

floating,screenedintakethatpreventsthe

circula-

tionofanysedimentthatmightaccumulateinthe

oil

pan.Bymeansofthispump,themainbearing

journals

andcrankpinsareefficientlylubricated

throughanoilgalleryandpassagesinthecylinder

block.

Oil

isforcedunderpressuretothemainbear-

ingsandthroughthecheeksofthecrankshaftto

theconnectingrodbearings.Oilisalsoforce-fed

tothecamshaftbearings,timinggears,andintake

valverockerarms.Theoilpressureiscontrolledby

relief

valvelocatedintheoilpump.Thevalveis

designedtoopenwhenexcessivepressure

develops

in

thesystem,relievingthepressureandreturning

the

excess

oiltotheoilpan.Thecylinderwalls,

pistonpins,andtappetsaresuppliedwithoilfrom

spurt

holes

intheconnectingrods.A portionof

theoiliscontinuallypassedthroughanoilfilter

which

effectivelyremovesanyforeignmattersus-

pendedintheoil.A flangedsectiononthe

rear

of

thecrankshaftactsasanoilslingerand,incom-

binationwiththe

rear

mainbearingupperand

loweroilseal,preventstheleakageofoilfromthe

rear

endofthecylinderblock.Leakageofoilfrom

thefrontendofthecylinderblockiscontrolled

bythecrankshaftoilslingerandthefrontoilseal

installedinthetiminggearcover.Theoilpressure

indicator

lightintheinstrumentpanelandtheoil

level

gauge

ordipstickinthesideofthe

engine

providea meansforcheckingtheoilpressureand

oil

level.

B-5.

OilPressureGaugeorIndicator

On

early

CJ-3B

vehiclesanoilpressure

gauge

is

mountedontheinstrumentpanel.

This

gauge

in-

dicatestheoilpressurewithinthe

engine

lubri-

catingsystem.

On

Models

CJ-5,

CJ-5A,

CJ-6,

CJ-6A,

DJ-5,DJ-6

and

laterproductionvehiclesofModel

CJ-3B

a

red

telltalelamp,whichoperateswhentheignition

switchisturnedon,islitwhenthereisinsufficient

oil

pressuretoproperlylubricatetheengine.When

it

goes

out,operatingpressureisachieved.In

normal

operation,thelightislitwhentheignition

isfirstturnedon.It

goes

outafterthevehicleis

in

motion.

Failure

ofthe

gauge

orindicatortoregisternormal

oil

pressuremayindicateinsufficientsupplyofoil

in

the

engine

crankcase,lowornooilpumppres-

sure,

ora faultinthe

gauge

orindicatorelectrical

circuit.

The

engine

mustbestoppedimmediately

topreventpossibledamageto

engine

bearingsand

thefaultcorrectedbeforerestartingtheengine.

B-6.

Engine

Lubrication

System—

DauntlessV-6Engine

The

engine

lubricationsystem(Fig.B-4)isthe

force

feed

typeinwhichoilissuppliedunderpres-

sure

tothecrankshaft,connectingrods,camshaft

bearingsandvalvelifters.Oilissuppliedundercon-

trolledvolumetotherockerarmbearingsandpush

rods.

Allothermovingpartsarelubricatedby

gravityfloworsplash.

The

supplyofoilis

carried

intheoilpanwhich

isfilledthrougha filteropeningintheright rocker

arm

cover.A removableoil

gauge

rodontheleft

sideofthecrankcaseisprovidedtocheckoillevel.

The

oilpumpislocatedinthetimingchaincover

10