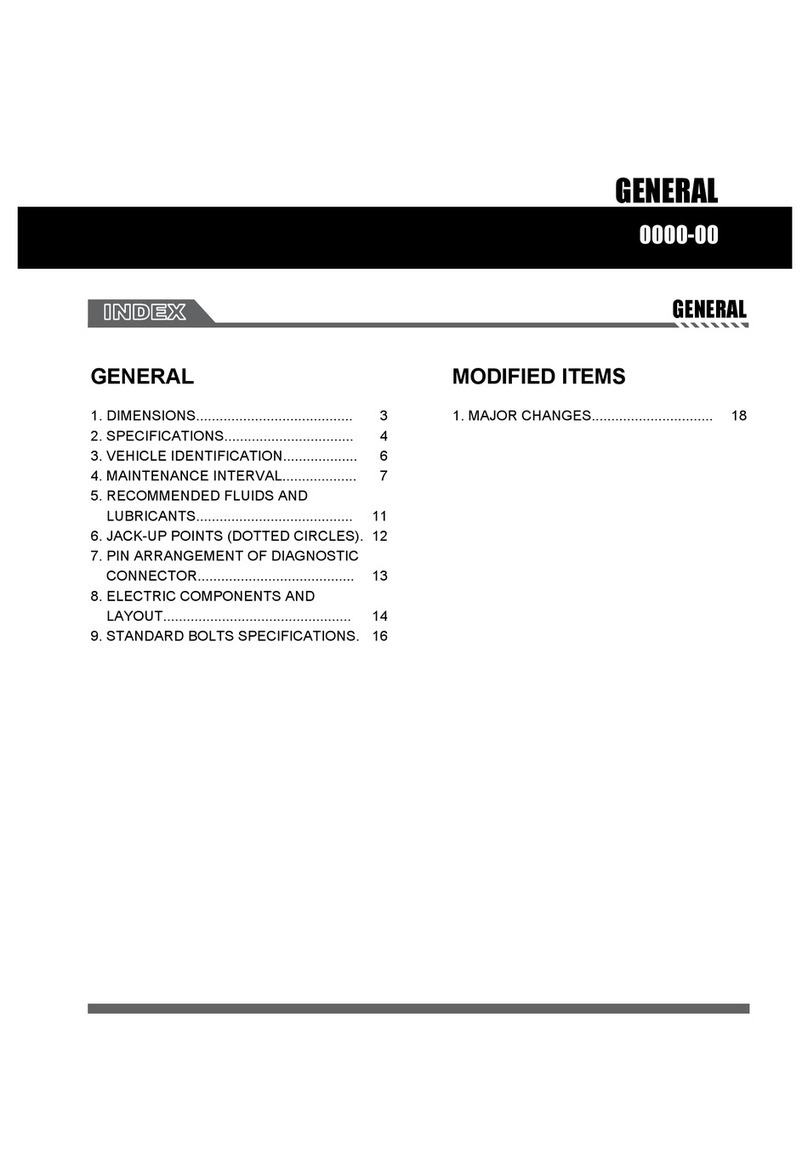

NEW STANDARDS

GI5

GI

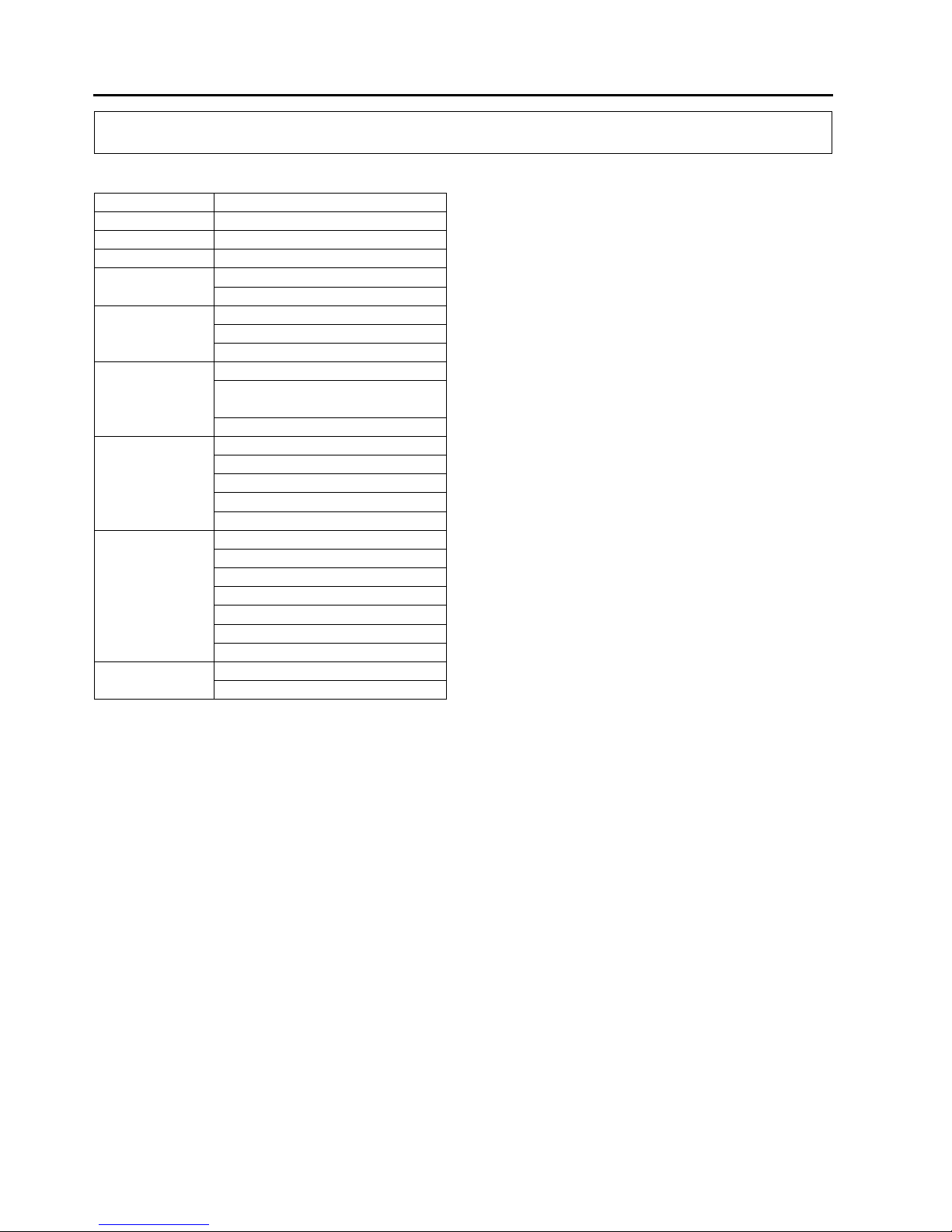

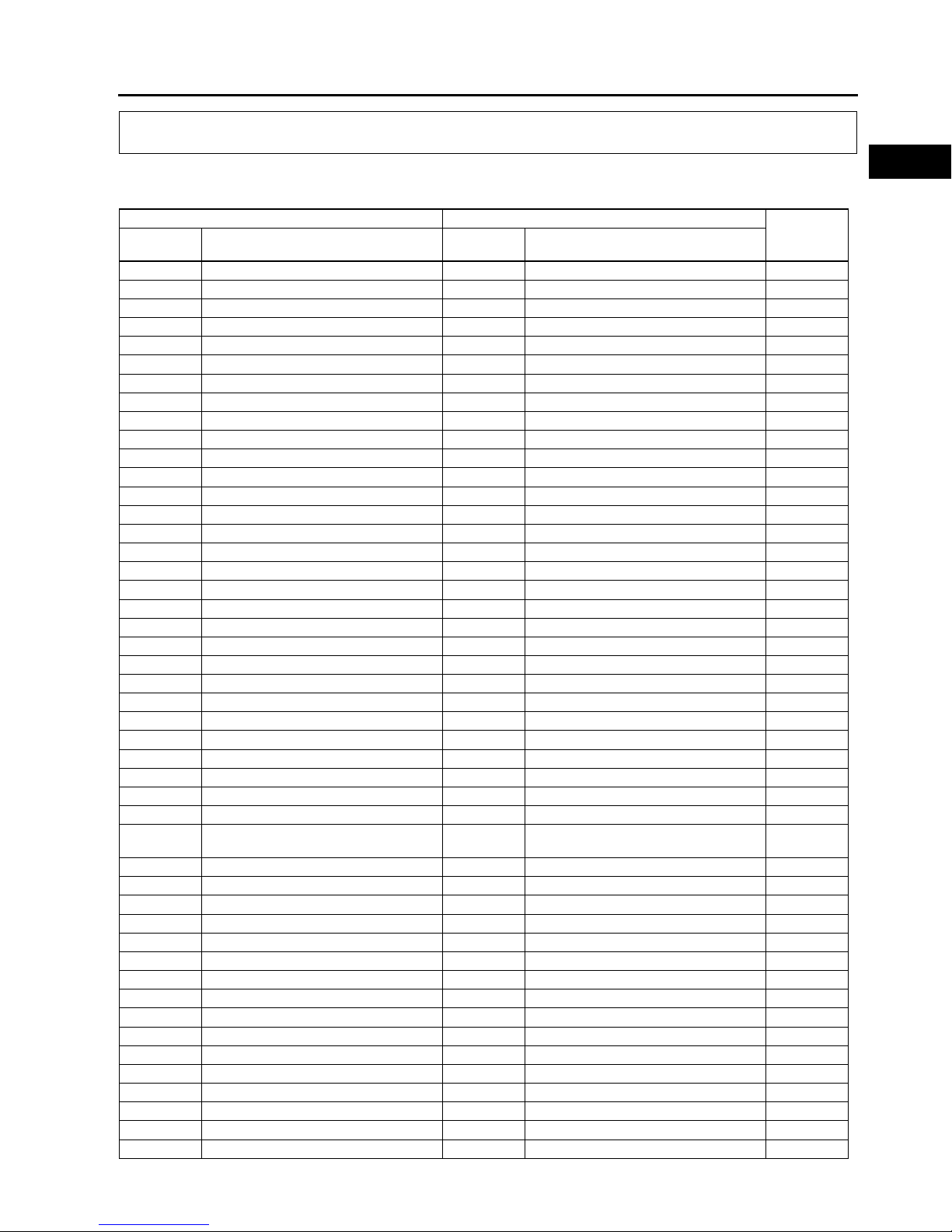

NEW STANDARDS TABLE A6E202800020T01

•Following is a comparison of the previo s standard and the new standard.

NEW STANDARDS

New Standard Previous Standard

Remark

Abbrevi-

ation Name Abbrevi-

ation Name

AP Accelerator Pedal Accelerator Pedal

ACL Air Cleaner Air Cleaner

A/C Air Conditioning Air Conditioning

BARO Barometric Press re Atmospheric Press re

B+ Battery Positive Voltage Vb Battery Voltage

Brake Switch Stoplight Switch

Calibration Resistor Corrected Resistance #6

CMP sensor Camshaft Position Sensor Crank Angle Sensor

CAC Charge Air Cooler Intercooler

CLS Closed Loop System Feedback System

CTP Closed Throttle Position F lly Closed

CPP Cl tch Pedal Position Cl tch Position

CIS Contin o s F el Injection System EGI Electronic Gasoline Injection System

CS sensor Control Sleeve Sensor CSP sensor Control Sleeve Position Sensor #6

CKP sensor Crankshaft Position Sensor Crank Angle Sensor 2

DLC Data Link Connector Diagnosis Connector

DTM Diagnostic Test Mode Test Mode #1

DTC Diagnostic Tro ble Code(s) Service Code(s)

DI Distrib tor Ignition Spark Ignition

DLI Distrib torless Ignition Direct Ignition

EI Electronic Ignition Electronic Spark Ignition #2

ECT Engine Coolant Temperat re Water Thermo

EM Engine Modification Engine Modification

Engine Speed Inp t Signal Engine RPM Signal

EVAP Evaporative Emission Evaporative Emission

EGR Exha st Gas Recirc lation Exha st Gas Recirc lation

FC Fan Control Fan Control

FF Flexible F el Flexible F el

4GR Fo rth Gear Overdrive

F el P mp Relay Circ it Opening Relay #3

FSO

solenoid F el Sh t Off Solenoid FCV F el C t Valve #6

GEN Generator Alternator

GND Gro nd Gro nd/Earth

HO2S Heated Oxygen Sensor Oxygen Sensor With heater

IAC Idle Air Control Idle Speed Control

IDM Relay Spill Valve Relay #6

Incorrect Gear Ratio

Injection P mp FIP F el Injection P mp #6

Inp t/T rbine Speed Sensor P lse Generator

IAT Intake Air Temperat re Intake Air Thermo

KS Knock Sensor Knock Sensor

MIL Malf nction Indicator Lamp Malf nction Indicator Light

MAP Manifold Absol te Press re Intake Air Press re

MAF sensor Mass Air Flow Sensor Airflow Sensor

MFL M ltiport F el Injection M ltiport F el Injection

OBD On-Board Diagnostic Diagnosis/SelfDiagnosis

OL Open Loop Open Loop