-8-

INSTRUCTION MANUAL

AIRFREE SERIES

4. Operation instructions

Operation Instructions

1. Please read the precautions very carefully before you start use.

2. Please confirm the wirings have been connected correctly, then

turn the main knob to “ON”. Now it’s powered on.

3. Press twice “start speed switch” to use “start speed switch” to

control the rotation speed.

4. Press twice “rotation button” to stop the motor. Then turn the

main knob to “OFF” the rotation completely stop.

5. You can also achieve the operation guide by scanning the QR

code.

5. Safety precautions

Do not bend the fan blades when installing, adjusting, and cleaning the fan, otherwise it will damage the equipment or affect the use of the equipment.

Before turn on the power please make sure that the input voltage of the fan is consistent with the power supply voltage.

Do not operate maintenance when the power is on.

Please correctly connect the input and output power cables and ground cables according to the markings on the control box.

After confirming that the wiring is correct, the product is energized for trial operation. After the trial operation is correct, it can run normally for a long

time.

If the fan fails and cannot be reset, please contact the manufacturer.

Do not operate the damaged equipment, otherwise it will bring unexpected and serious consequences.

It is strictly prohibited to run the fan when the safety space is insufficient.

It is strictly forbidden to work inside the fan operating space. Please confirm whether there are obstacles before turning on the fan.

It is recommended that before the machine is powered off, please press the "knob key" to stop the machine, and turn off the power after the device has

completely stopped rotating.

If the machine has not been used for more than 2 months, please pre-charge the product when it is used next time: Turn on the power and waiting more

than 15mins to start the rotation.

Warning: Before operation please read the manual very carefully. Remove obstacles in the operating area to ensure

that the fan runs with safe distance. Before operate any maintenance please make sure you already turned off the

power supply. The operation must be done by professionals to avoid being injured.

Attention

1. Make sure that there are no obstacles and potential hazards in

the fan operating space.

2. Make sure that the input power is correct and meet the product

requirements.

3. Make sure that the speed knob points to the minimum position.

4. Start the equipment and turn the switch from “stop” to “run”.

5. After the fan runs, adjust the rotation speed knob to achieve the

best effect.

1. Stop the equipment and shut down the controller strictly

according to the operating instructions;

2. Please do not cut the power off during the running.

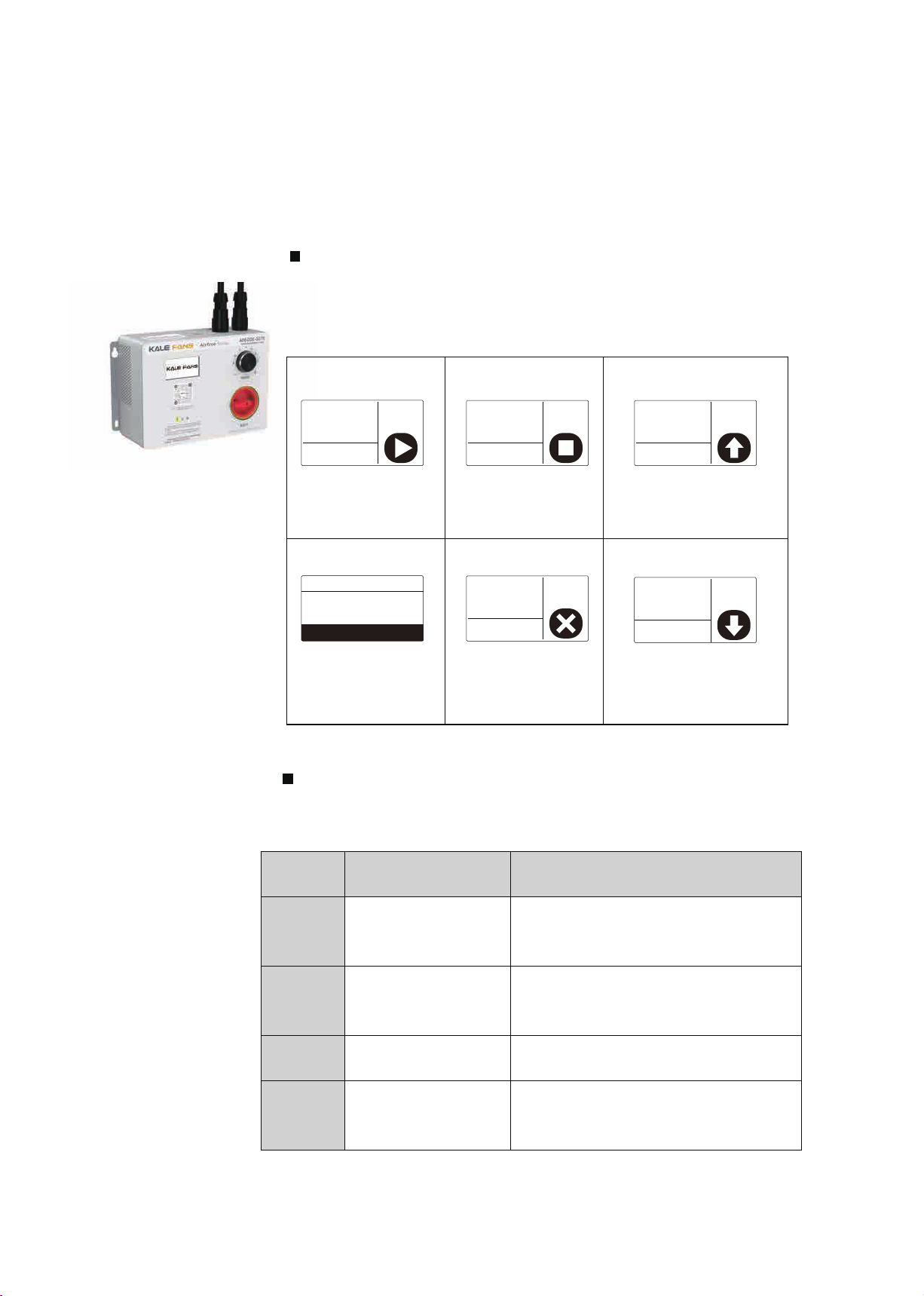

How to start: How to stop:

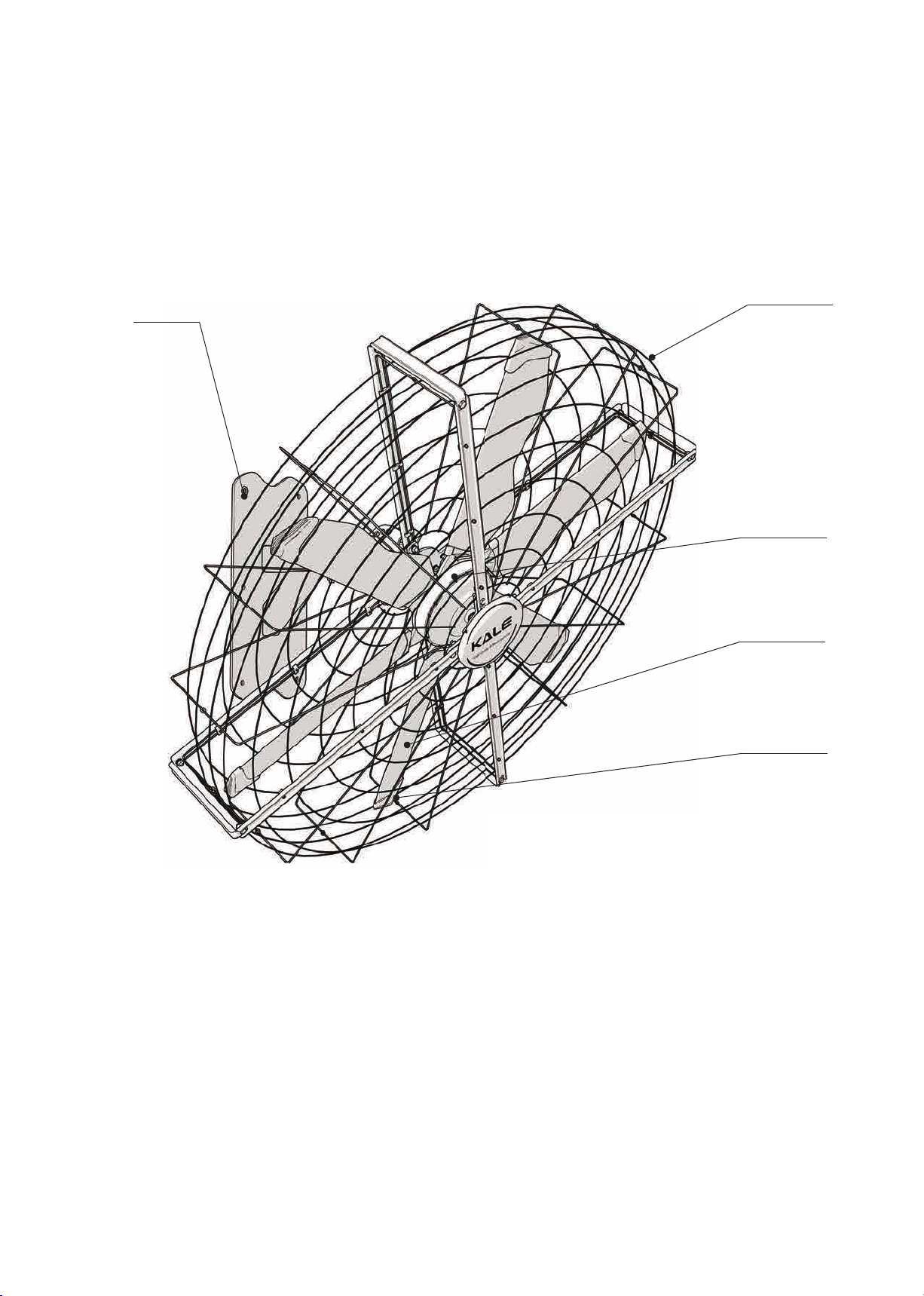

Rotation master button

Start speed switch

LCD Screen

Function Description:

1. LED display: The user does not have any operation on the

product within 1 minute, the LCD screen turns from bright to dark,

and the brightness is restored after operation.

2. Main switch: When the switch points to OFF , it powered off;

when the switch points to ON , it powered on.

3. Rotation speed button: multi-function knob. Please check the

above table to know the details.

2. Main switch: When the switch points to OFF , it powered off;

when the switch points to ON , it powered on.

Function Adjust Rotation speed Start, Stop button Malfunction Reset

Definition

Clockwise rotate the

“Rotation speed” button

to increase speed.

And anticlockwise to slow

down the speed.

Press once

“Rotation speed”

button to start

and stop.

When malfunction appears,

press once “Rotation speed”

button to reset it. If the reset

doesn’t work you should

contact KALE following the

guide shown on screen.

Notice: Short press of "Rotation speed switch": the duration is less than 2s;

Long press of "Rotation speed switch": more than 2s;