Liquid NanoParticle Sizer User Guide iii Version 1.0.1

Table of Contents

About This Manual.................................................................................................................1

Intended Audience ..............................................................................................................1

Scope of User Manual..........................................................................................................1

Definitions ............................................................................................................................1

Safety and Handling Procedures...........................................................................................2

Safety Signals........................................................................................................................2

Warnings...............................................................................................................................3

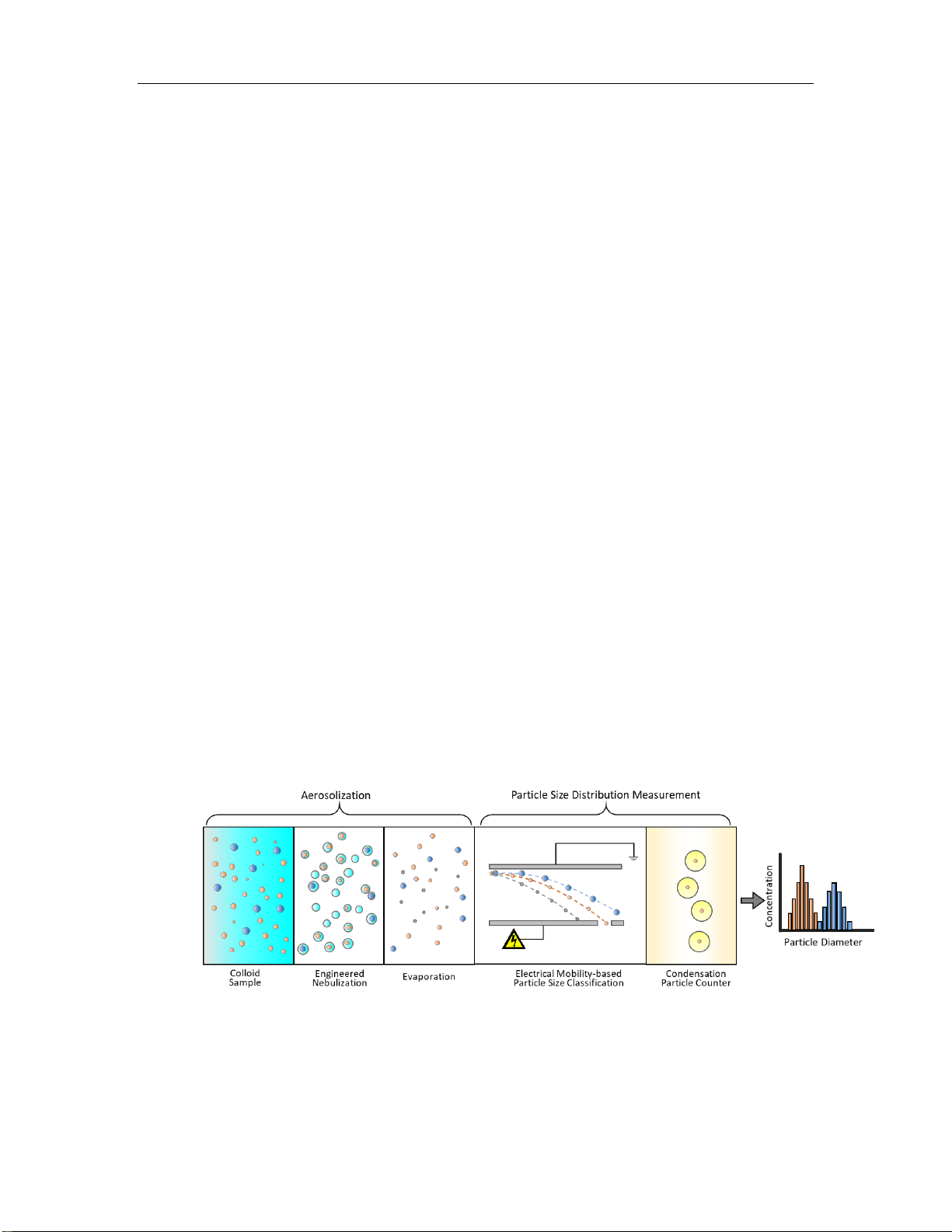

How the Liquid NanoParticle Sizer Works..........................................................................4

Applications .........................................................................................................................5

Acknowledgement...............................................................................................................5

How to Install the Liquid NanoParticle Sizer Model 9310 ................................................7

Installation Overview ..........................................................................................................7

Unpacking the NanoParticle Nebulizer .............................................................................7

Unpacking the Annular Flow Ion Mobility Classifier.......................................................8

Unpacking the Fast CPC......................................................................................................9

Unpacking the LNS Accessory Kit .....................................................................................9

Equipment You Need ........................................................................................................11

Flaring a Tube.....................................................................................................................12

Installing the NanoParticle Nebulizer..............................................................................12

Connecting the Water Drain ...................................................................................................... 13

Connecting the Compressed Air or Nitrogen Supply.............................................................. 14

Connecting the Power ................................................................................................................ 15

Connecting the Ultrapure Water Supply .................................................................................. 15

Connecting the Sample Inlet...................................................................................................... 16

Controlling the External Injection Pump with the NanoParticle Nebulizer ........................... 18

Warming Up the Nebulizer ....................................................................................................... 19

Installing the Annular Flow Ion Mobility Classifier .......................................................20

Connecting Gas Port B to Gas Port C ........................................................................................ 22

Connecting CDA to Gas Port A ................................................................................................. 22

Connecting the Exhaust.............................................................................................................. 23

Connecting the Power ................................................................................................................ 23

Connecting the Aerosol Input.................................................................................................... 24

Connecting the Aerosol Outlet .................................................................................................. 25

Installing the Fast CPC ......................................................................................................27

Connecting the AFIMC .............................................................................................................. 29

Connecting the n-Butanol Supply ............................................................................................. 30

Connecting the Exhaust.............................................................................................................. 31

Connecting Make-Up Air........................................................................................................... 32

Connecting the Power ................................................................................................................ 34

Connecting the BNC Cable ........................................................................................................ 34

Warming Up the Fast CPC......................................................................................................... 36

Installing the Kanolysis Model S330 Software.................................................................37

Installing the Kanolysis Software .............................................................................................. 37

Upgrading the Kanolysis Software............................................. Error! Bookmark not defined.