Release the start handle gently instead of suddenly to protect

the starter from being damaged.

!CAUTION

Starting up in high altitude regions

In high altitude places, standard carburetor produces a dense mix of fuel and

air, resulting in decreases in the engine performance and increased fuel

consumption. To keep the engine with high performance, install a carburetor

main spray nozzle and readjust the idle speed screw.

Contact your dealer for replacing the carburetor and to make adjustments in

advance. Even with a proper nozzle modification on the engine, the engine

power output will decrease about 3.5% with each 305m over sea level.

Opera t i n g i n s t r u c t i o n s

Start and warm up the engine, and then close the choke gradually.

Set the throttle valve in accordance with specified rational speed.

Stopping

Move throttle handle to the extreme right end.

Set the engine switch to OFF.

1

2

1

2

Once a carburetor was changed to used in high altitud places.

Operation at lower altitudes may cause serious engine damage

!CAUTION

12

Set the engine switch to OFF

Move the throttle valve to the right

+

Before maintenance and service, turn off the engine. If the engine should

run, make sure that the engine is in a well-ventilated area. Exhaust

emissions from the engine contains toxic carbon monoxide (CO2), which

may cause loss of consciousness and even life.

Only use genuine KATSU POWER parts and specified

maintenance tools or the water pump may be damaged.

!CAUTION

17

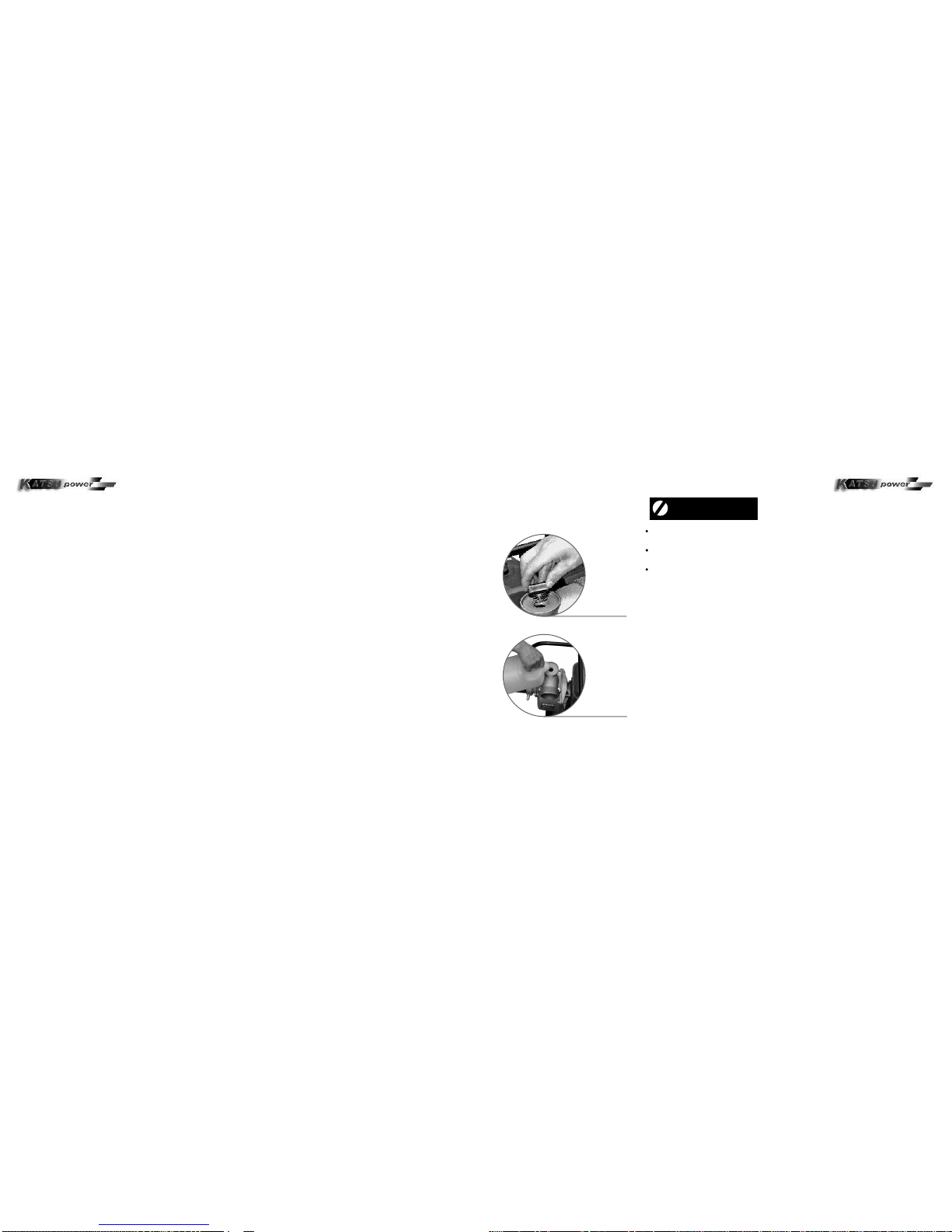

NOTE

(1) Use in extremely dusty area, the job

should be done more often.

(2) Should be done by your dealer, unless

you are equipped with proper repair tools,

and are proper trained and are qualified

mechanically.

FRECUENCY EACH WHICHEVER COMES FIRST

TIME ITEMS

OIL LEVEL O

OIL CHANGE O

AIR CLEANER CHECK O

CHANGE O(2)

EVERY 100 HOURS RUNNING-LEAN

EVERY TWO YEAR REPLACE O(2)

O(2)

SPARK PLUG

VALVE CLEARANCE ADJUSTMENT

CLEAN COMBUSTION CHAMBER

SPARK ELIMINATOR

FUEL SUPPLY PIPE

IMPELLER CHECK

WATER PUMP TANK COVER

WATER INLET VALVE CHECK O(2)

FIRST MONTH

OR 20 HOURS EVERY 3 MONTH

OR 50 HOURS EVERY 6 MONTH

OR 100 HOURS EVERY YEAR

OR 300 HOURS

ENGINE OIL CHECK O

O(1)

O(1)

OWNER MANUAL DCA KAT S U P O W E R WAT E R P U M P S OWNER MANUAL DCA KAT S U P O W E R WAT E R P U M P S