Kelly KBL36101 User manual

Other Kelly Controllers manuals

Kelly

Kelly KLS7212N User manual

Kelly

Kelly KBS24051 User manual

Kelly

Kelly KDZ72650E User manual

Kelly

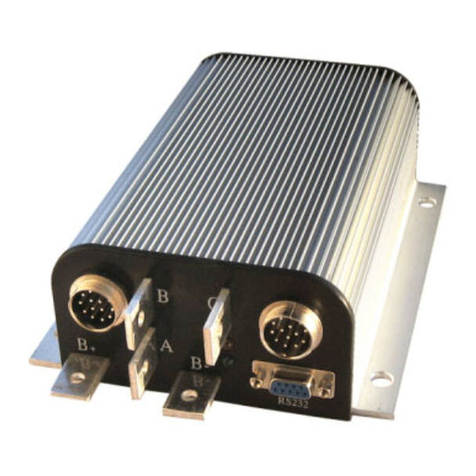

Kelly KLS8425RM User manual

Kelly

Kelly KDZ Series User manual

Kelly

Kelly Cheetah Series User manual

Kelly

Kelly KLS8080I/IPS User manual

Kelly

Kelly KLS4860NE User manual

Kelly

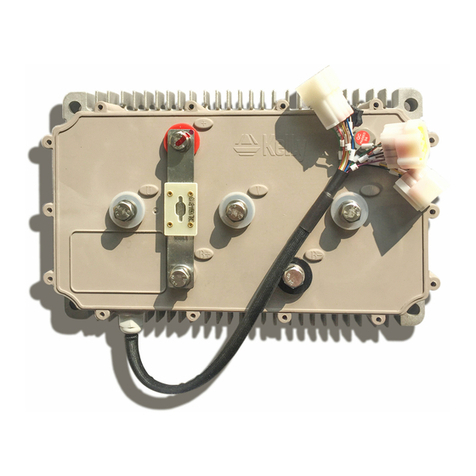

Kelly Puma mini KLS-N Series User manual

Kelly

Kelly HIGH VOLTAGE KHDA Series User manual

Kelly

Kelly Jaguar KLS8418N User manual

Kelly

Kelly KLS8080N User manual

Kelly

Kelly SPM4812S User manual

Kelly

Kelly MiniKLS7210NV User manual

Kelly

Kelly KLS6022H User manual

Kelly

Kelly KLS Series User manual

Kelly

Kelly KLS72501-8080N User manual

Kelly

Kelly KLS7270NE User manual

Kelly

Kelly KLS-N User manual

Kelly

Kelly KLS2412ND User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions