10

SNA-Series Tankless Heater Installation

10/17/2014 Keltech • 215-1815 Rev. B; ECN 130011

Perform Operational Test No. 1

AEnsure the enclosure door is closed.

BSet the 3-pole switch or circuit breaker to the

ON Position.

C

Pull out the Emergency Stop Button, heater will

automatically perform a 6 second discharge

from the TepidGuard overshoot purge system.

Wait for purge cycle to complete.

E

Test water temperature and stability at

outlet by viewing the display. Controller

displays (in red) the temperature of water

exiting the heater.

F

Deactivate the shower or eyewash. The

flow sensor will electrically open contacts

and remove power from the elements and

controller so that the display is blank and

bank lights are off. Power light stays on.

D

When flow rate reaches approximately

1.5gpm, the flow sensor recognizes this

condition and begins the heating process.

When the flow sensor activates:

• Green bank energized lights illuminate on the

front bezel verifying power supply connection to

the heating elements via the solid-state relays.

• Element load lights may be solid or flash

in unison as heating elements modulate

depending on the hot water demand.

• Digital temperature controller shows water

temperature. Additional programming is

not necessary.

Located on the panel are 1 (36-63kW) or

2 (72kW-144kW) green ready lights. When

illuminated, the safety circuit is engaged

and ready for use.

Heaters installed in pump-and-well supplied

water systems may require an operating

pressure adjustment to a differential pressure

of approximately 10 psi. For example, if the

high limit pressure is 40 psi, adjust the low

limit pressure to 30 psi with the pressure

switch located on the supply pump.

Heater will not energize heating elements if the

inlet water temperature is equal to or greater than

the temperature set on the digital controller .

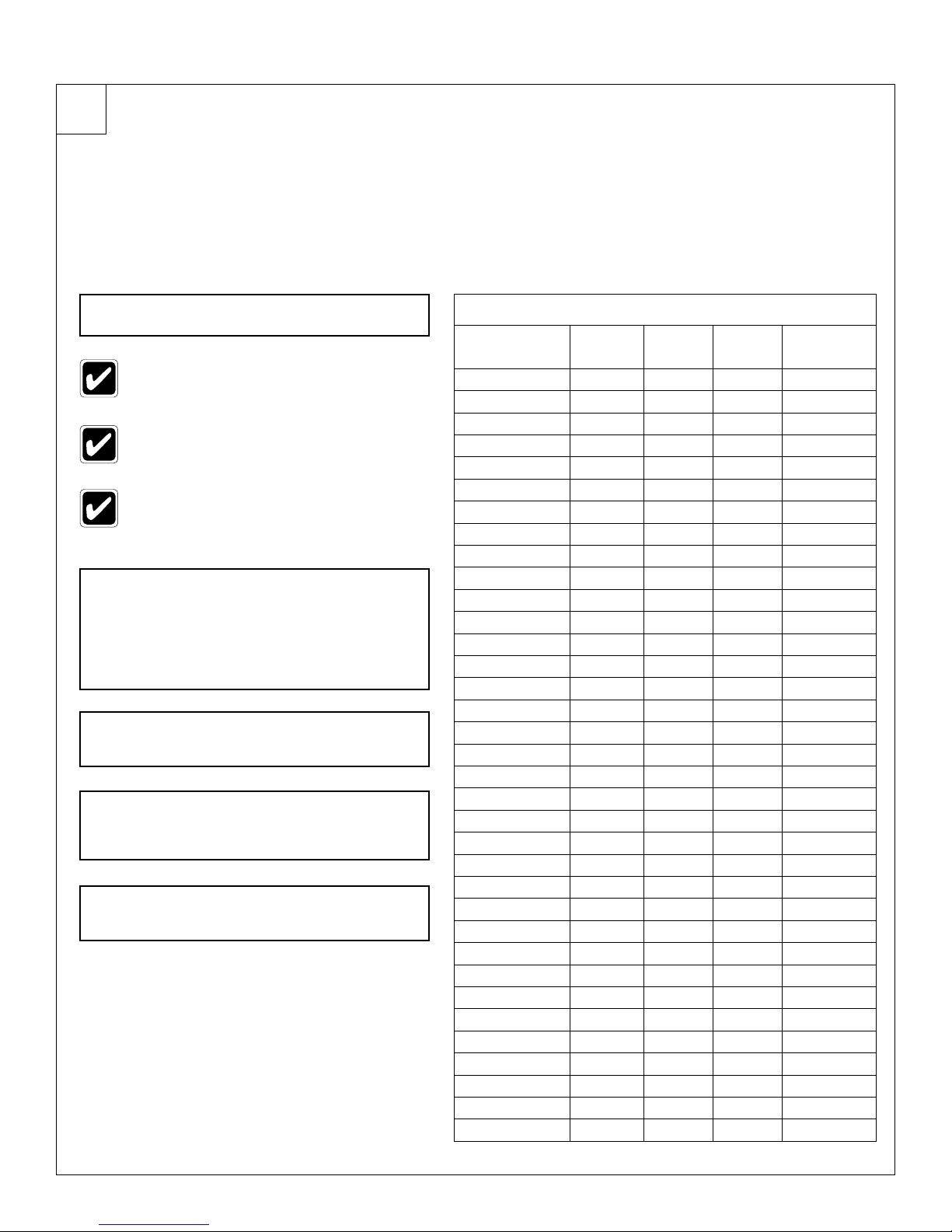

If the water flow exceeds maximum heating capacity of the heater, the temperature of water at the

outlet may be lower than the temperature selected on the controller. See Table 3 to determine maximum

temperature rise capabilities.

Maximum Temperature Rise (GPM & °F)

Low Flow Activation* (1.5gpm) High Flow Activation*(15 gpm)

Models

480/600V

kW Low/

High

2.5 gpm

ΔT °F

3 gpm

ΔT °F

5 gpm

ΔT °F

8 gpm

ΔT °F

15gpm

ΔT °F

20gpm

ΔT °F

25 gpm

ΔT °F

30gpm

ΔT °F

35gpm

ΔT °F

40 gpm

ΔT °F

45gpm

ΔT °F

50gpm

ΔT °F

SNA-363 12/36 33 27 16 10 16 12 10

SNA-543 18/54 49 41 25 15 25 18 15 12 10

SNA-633 24/63 57 57 29 20 29 22 17 15 12

SNA-723 27/72 73 61 37 23 32 24 19 16 14 10

SNA-1083 40/108 109 90 54 34 49 36 29 24 21 18 16 14

SNA-1263 47/126 128 106 64 40 57 43 34 28 24 21 19 17

SNA-1443 54/144 147 122 73 46 65 49 39 33 28 24 21 19

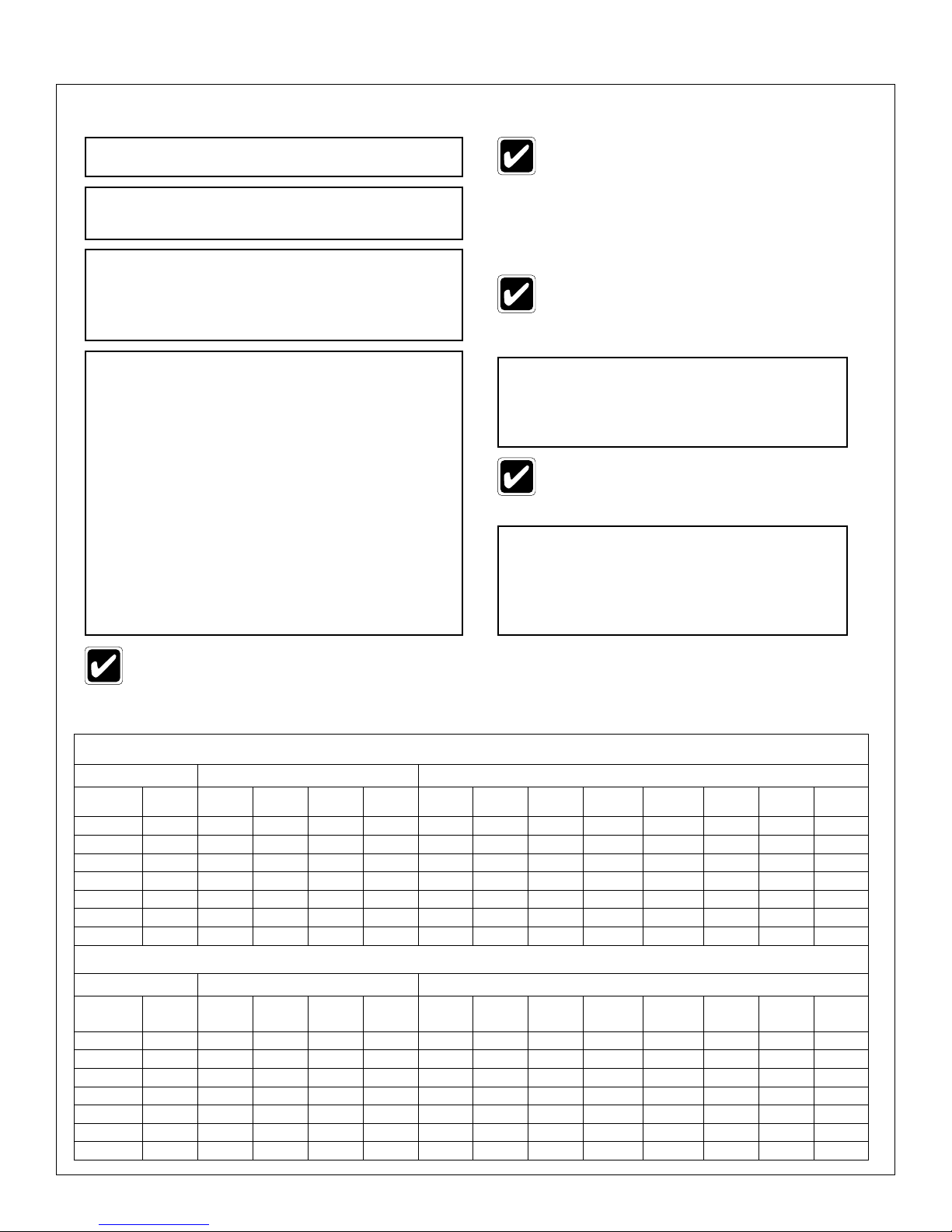

Maximum Temperature Rise (LPM & °C)

Low Flow Activation* (1.5gpm) High Flow Activation*(15 gpm)

Models

480/600V

kW Low/

High

9.5 lpm

ΔT °C

11.3 lpm

ΔT °C

18.9 lpm

ΔT °C

30.3 lpm

ΔT °C

56.7 lpm

ΔT °C

75.6 lpm

ΔT °C

94.5 lpm

ΔT °C

113.4 lpm

ΔT °C

132.5 lpm

ΔT °C

151 lpm

ΔT °C

170.3lpm

ΔT °C

189.3lpm

ΔT °C

SNA-363 12/36 18 15 9 6 9 7 6

SNA-543 18/54 27 23 10 8 14 10 8 7 6

SNA-633 24/63 32 32 16 11 16 12 9 8 7

SNA-723 27/72 40 34 21 13 18 13 11 9 8 6

SNA-1083 40/108 60 50 30 19 27 20 16 13 12 10 9 8

SNA-1263 47/126 71 59 36 22 32 24 19 16 13 21 11 9

SNA-1443 54/144 82 68 41 26 36 27 22 18 16 13 21 11

TABLE 3

…continued on next page