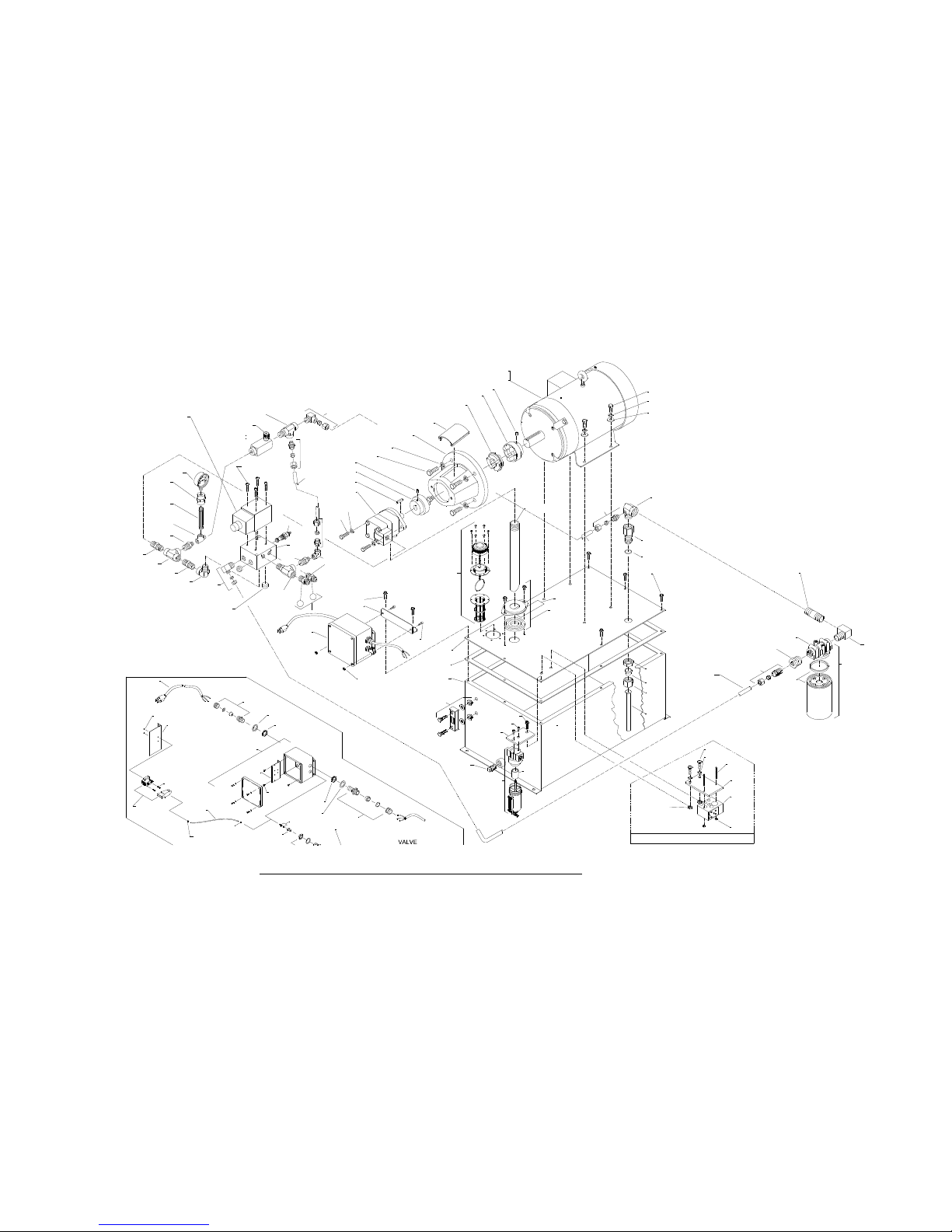

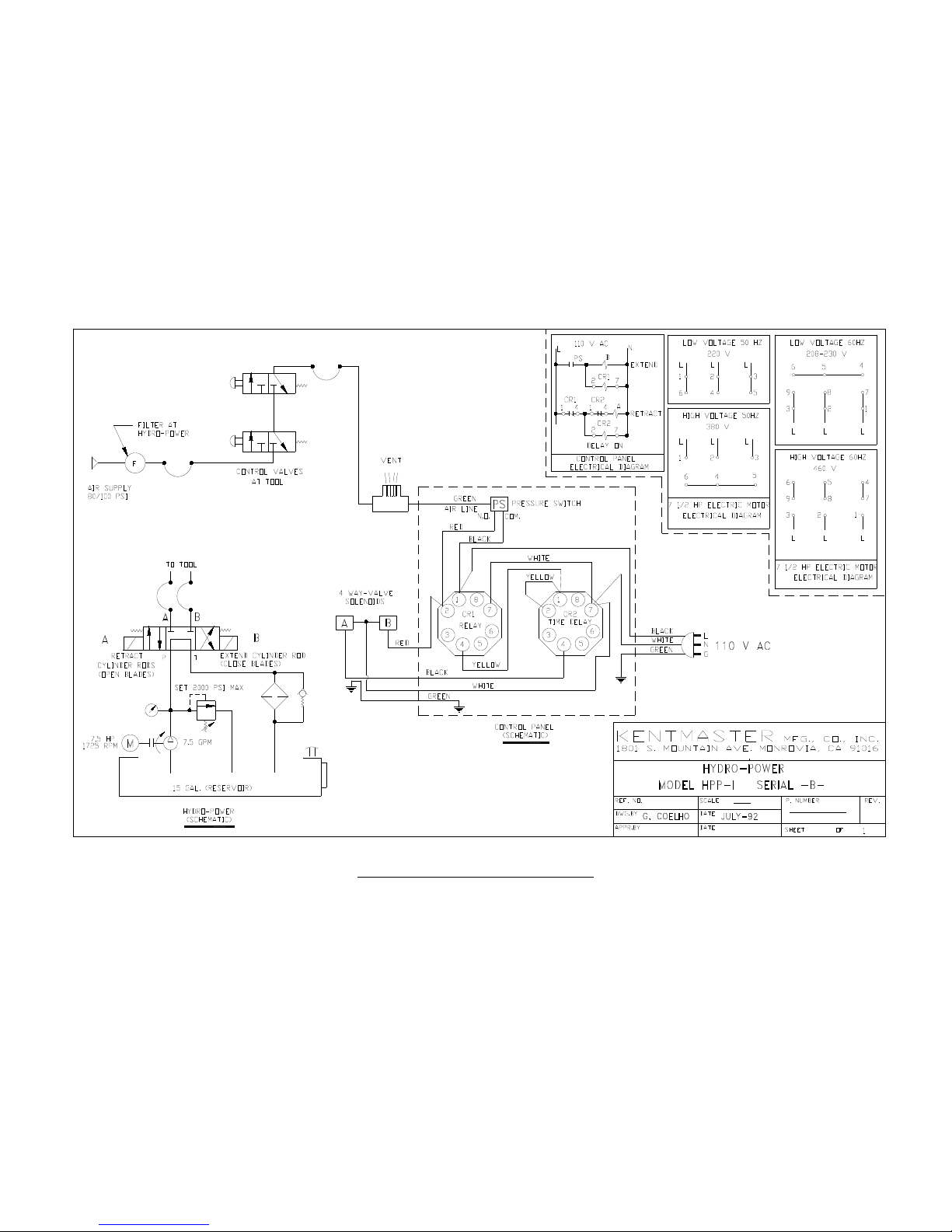

KENTMASTER MODEL HPP-I-F

001 1 CONNECTOR, CABLE 1

001 9 CONNECTOR, CABLE 1

00708 CORD, POWER - USA 115V (SINGLE PHASE) 1

0081 LOCKNUT

00816 RING, SEAL

00905 SWITCH, SUB. PRES/ELECT. 1

00918 MOTOR, ELECTRIC (10 HP - 60 Hz) 1

00934 MOTOR, ELECTRIC (10 HP - 50 Hz) 1

651510 BRACKET, MOTOR-PUMP 1

651513 COUPLING, MOTOR SIDE 1

651514 COUPLING, PUMP SIDE 1

651515 INSERT, COUPLING 1

651516 RESERVOIR 1

651518 BRACKET, CONTROL BOX 1

651519 PLATE, AIR FILTER 1

6515 5 TUBING 1

6515 6 PLUG, MODIFIED 1

6515 7 GASKET 1

6515 8 COVER, BRACKET 1

651530 PLATE, NAME 1

6515 NIPPLE, MODIFIED 1

651544 TUBING, RETURN 1

651611* BRACKET, MODULE 1

700004 PLUG, PIPE

700014 PLUG, PIPE 1

7004 1 ELBOW, 90° STREET 1

700111 COUPLING, PIPE 1

700175 NIPPLE, HEX LONG 1

700 0 NIPPLE, LONG 1

700 67 NIPPLE, HEX

700314 ELBOW, STREET 1

7003 0 TEE 1

700360 NIPPLE, HEX 1

700373 BUSHING 1

700380 PLUG 1

700073 TEE, MALE RUN 1

700846 MALE RUN TEE

700931 NUT, BULKHEAD 1

70093 NUT 1

700933 SLEEVE 1

700934 O-RING 1

701075 ELBOW, MALE (RETURN) 1

70114 CONNECTOR, MALE 1

701870 FITTING, BULKHEAD 1

701871 CLAMP, PRESS-ON HOSE

70187 ADAPTOR, PIPE TO FEMALE ADAPTOR 1

701873 FITTING, HOSE 1

7 0005 FILTER, AIR 1

7 0006 ELEMENT, AIR FILTER 1

7 00 0 FILTER, RETURN 1

7 00 1 ELEMENT, FILTER 1

7 00 HEAD, FILTER 1

730354 HOSE, HYDRAULIC 1

7801 5 FLANGE, TANK 1

7801 8 BREATHER, FILLER 1

7801 9 GAUGE, LIQUID LEVEL 1

780301 GAUGE, PRESSURE (0-3000) 1

780431* MODULE, AIR LOGIC 1

780470 PUMP 1

7804751 VALVE, COMPLETE DIRECTIONAL ( 0V) 1

780480 PLATE, SUB 1

80 305 SCREW, SWITCH

80 816* SCREW, MODULE

811004 SCREW, AIR FILTER

8 11 0 SCREW, DIRECTIONAL VALVE 4

831303 SCREW, COUPLING SET 1

831305 SCREW, COUPLING SET 1

841105 SCREW, WIRE BOX

841508* SCREW, MOTOR 6

841510 SCREW, PUMP

84181 SCREW, MOTOR BRACKET 4

84 7 5 SCREW, HEX 9

84 730 SCREW, PANEL 3

850003 NUT, PANEL HEX

850008* NUT, MODULE PANEL HEX 6

850011 NUT, PANEL HEX

850015* NUT, PLATE HEX

850516* WASHER, MOTOR 4

850616 WASHER, MOTOR PUMP 8

850618 WASHER 4

860308 KEY, PUMP 1

PART NO. DESCRIPTION QTY QTY

DESCRIPTION

PART NO.

*FOR USE WITH ANTI-TIE DOWN

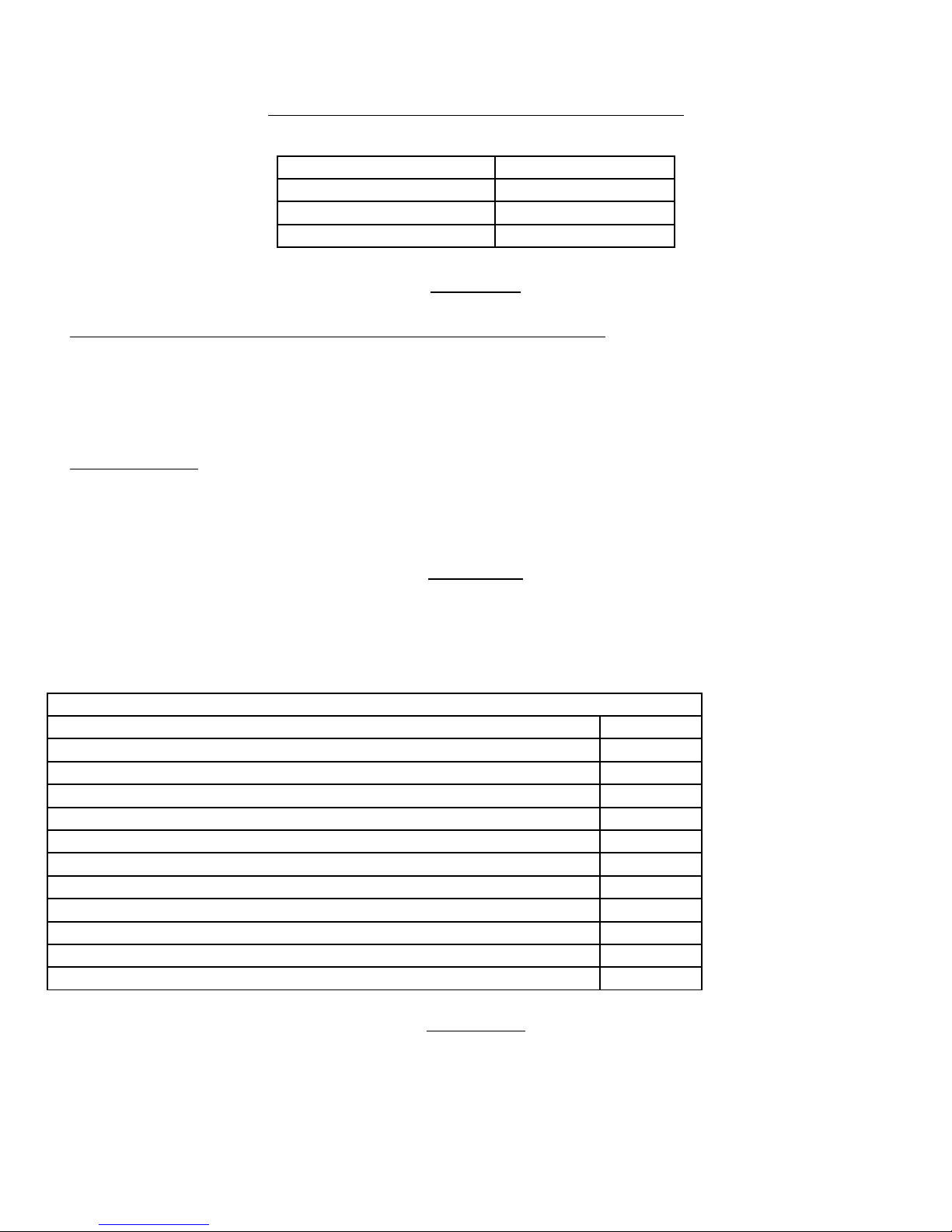

780478 RELIEF CARTRIDGE 1

700043 ELBOW, 90° STREET 1

700 65 NIPPLE, HEX 1

651517 COVER, RESERVOIR 1

651547 ASSEMBLY, WIRE BOX 1

651610 STREET ELBOW, MODIFIED 1

651546 TUBING, RETURN 1

651545 WIRE BOX, MODIFIED 1

70041 MALE RUN TEE 1

700930 CONNECTOR, FEMALE BULKHEAD 1

701137 CONNECTOR, MALE 1

701 15 CONNECTOR, MALE

780481 FLOW CONTROL VALVE 1

00709 CORD, POWER - USA 0V (SINGLE PHASE) 1

00714 CORD, POWER - EURO 0V (SINGLE PHASE) 1

700193 NIPPLE, HEX LONG 1

780475 VALVE, COMPLETE DIRECTIONAL (110V) 1

730367 HOSE, HYDRAULIC STRAIGHT ENDS 1

730001 HOSE 1

6515550 "SOFT STOP" RETURN LINE 1