Kersten UBS Hydro II User manual

Translation of the original

instructions

UBS Hydro II

Order number: B00085 From machine number: Rev.: R00 Issued: 2018-05-02

Distributed in UK by

Kersten (UK) Ltd Tel. 0118 986 9253

Progrees House

39 Boulton Road Reading, RG2 0NH

www.kerstenuk.com - [email protected]

Manufactured by

Kersten Arealmaschinen GmbH

Empeler Straße 95

D - 46459 Rees

www.kersten-maschinen.de

EN

2018-05-02 2 / 60

All rights reserved. This documentation is protected by copyright. Kersten Arealmaschinen GmbH reserves

all rights that have not been granted explicitly. Without a prior, written consent and except in legally permitted

cases, this document may neither be reproduced and distributed nor made publicly accessible in any other

way.

This document is subject to changes without prior notice. The original document has been issued in German.

All translations are copies of the original document.

Copyright 2018 with Kersten Arealmaschinen GmbH

Kersten Arealmaschinen GmbH

Empeler Straße 95

46459 Rees, Germany

Germany

Phone: +49 2851 9234-10

Fax: +49 2851 9234-44

Info@kersten-maschinen.de

http://www.kersten-maschinen.de/

EN

2018-05-02 3 / 60

Information concerning the Operating Instructions

These Operating Instructions ensure the safe and efficient handling of the

machine. These Operating Instructions are part of the machine and must be kept

easily accessible for the staff at all times near the machine.

The staff must carefully read and understand this manual before starting the work.

Basic prerequisite for a safe working is to adhere to all the safety and handling

instructions mentioned in this manual.

Risk of accident and damages to property if not used properly!

Because self-propelled working machines and attachments can cause serious

accidents or hazards if not properly operated, it will be required for the initial

commissioning of the Kersten machines that you are instructed by a specialised

and authorised person. Preferably, you make yourself familiar with its basic

functions and its operation by testing it for the first time on an open and plane

ground.

•For further information and in case any problems occur whatsoever they

may be, please contact your seller, importer or directly ask the manufacturer.

•Also inform all other users about these safety instructions!

Apart from these, the local industrial safety regulations and the general safety

provisions are applicable for the area of use of the machine.

Other applicable documents

Apart from these Operating Instructions, the following documents and the safety

instructions given in these documents are also to be followed:

•Operating Instructions for supplied components

•Operating Instructions for the host vehicle

Customer service provided by the manufacturer

Please contact the customer service of the manufacture of the machine for

technical information:

Manufacturer's address

Kersten Arealmaschinen GmbH

Empeler Straße 95

46459 Rees, Germany

Germany

Service telephone

+ 49 2851 9234-10

Fax

+ 49 2851 9234-44

E-mail

Info@kersten-maschinen.de

Website

http://www.kersten-maschinen.de

Please have the following information ready for inquiries:

•Machine / device type

•Order number of the machine

•In case of problems: exact description or exact fault messages

EN

2018-05-02 4 / 60

1Preface 6

2Safety 7

2.1 Symbols in these instructions............................................................................................................. 7

2.2 Pictograms ......................................................................................................................................... 8

2.3 Intended use..................................................................................................................................... 10

2.4 Work areas and danger zones......................................................................................................... 11

2.5 Safety during the working process................................................................................................... 12

2.6 Safety equipment ............................................................................................................................. 14

2.6.1 Emergency shut-down via the dead man lever........................................................................... 14

2.7 Safety signage.................................................................................................................................. 15

2.8 Residual risk..................................................................................................................................... 15

2.9 Environment protection .................................................................................................................... 18

2.10 Safety instructions for maintenance / trouble shooting .................................................................... 19

2.11 Safety instructions for dismantling and disposal.............................................................................. 21

3Functional description 22

3.1 Overview........................................................................................................................................... 22

4Transport, Packaging and storage 24

4.1 Safety instructions............................................................................................................................ 24

4.2 Transport inspection......................................................................................................................... 24

4.3 Packaging......................................................................................................................................... 24

4.4 Transport of the machine ................................................................................................................. 25

5Assembly/set up, installation, first commissioning 27

5.1 Safety instructions............................................................................................................................ 27

5.2 Assembly of attachments................................................................................................................. 27

5.3 Assembly of grid wheels (optional) .................................................................................................. 28

6Operation 30

6.1 Safety instructions............................................................................................................................ 30

6.2 Starting the engine........................................................................................................................... 30

6.3 Moving off / switching on the auxiliary drive..................................................................................... 31

6.4 Steering............................................................................................................................................ 33

6.5 Switching off of combustion engine.................................................................................................. 34

6.6 Tilting of steering bar........................................................................................................................ 36

6.7 Tilting of the operating panel............................................................................................................ 37

6.8 Swivel the operating unit to the side ................................................................................................ 38

7Maintenance 39

7.1Safety instructions............................................................................................................................ 39

7.2 Spare parts....................................................................................................................................... 39

7.3 Maintenance work ............................................................................................................................ 39

7.3.1 Check safety devices for function ............................................................................................... 39

7.3.2 Daily check.................................................................................................................................. 40

7.3.3 Maintenance after 20 operating hours / longer down-time ......................................................... 41

7.3.4 Maintenance after 100 operating hours / longer down-time ....................................................... 42

EN

2018-05-02 5 / 60

7.4 Check the belt drive of the auxiliary drive ........................................................................................ 43

7.5 Maintenance of wearing bush .......................................................................................................... 45

7.6 Measures after maintenance is done............................................................................................... 46

7.7 Storage............................................................................................................................................. 46

8Faults / fault removal 47

8.1 Safety instructions............................................................................................................................ 47

8.2 Cause of a malfunction and its elimination....................................................................................... 47

8.3 Error list - petrol engine.................................................................................................................... 47

8.4 Error list E-Start equipment.............................................................................................................. 49

8.5 Error list - traction drive.................................................................................................................... 49

8.6 Error list - drive line .......................................................................................................................... 50

9Dismantling, disposal 51

9.1 Safety instructions............................................................................................................................ 51

9.2 Dismantling....................................................................................................................................... 51

9.3 Disposal............................................................................................................................................ 51

10 Technical data 53

10.1 General............................................................................................................................................. 53

10.2 Types of engine................................................................................................................................ 54

10.3 Electrical circuit diagrams................................................................................................................. 57

10.3.1 Without battery............................................................................................................................ 57

10.3.2 With battery................................................................................................................................. 58

10.4 Declaration of conformity.................................................................................................................. 59

UBS Hydro II

Preface EN

2018-05-02 6 / 60

1 Preface

Dear customer,

Thank you for choosing a quality product from the company Kersten.

This product was produced using the most modern manufacturing techniques and

extensive quality assurance measures because only then when you are satisfied

with your product our goal will be achieved.

Before the first use of this machine or the attachment, please read these Operating

Instructions fully and conscientiously.

In case you do not understand any items of this safety data sheet or of the product-

specific assembly and operating instructions, please contact your seller or directly

ask the manufacture of the machine.

Keep these Operating Instructions handy for future reference. If necessary, you will

be able to look up important information and instructions there.

We hope you enjoy your Kersten machine

Dipl.- Ing. (FH) Robert Bosch

Managing Director

UBS Hydro II

Safety EN

2018-05-02 7 / 60

2 Safety

2.1 Symbols in these instructions

Safety instructions

The following symbols referring to occupational safety are used for all safety notes

that indicate the danger to life and limb for persons and are marked by a

pictogram, a signal word or a signal colour.

Please find the descriptions of the dangerous situation in the corresponding items

of the documentation.

Please observe these notes!

Observe the locally applicable safety and accident prevention regulations!

DANGER

Type and source of danger

This symbol warns against an immediate risk to the life and health of persons.

Nonobservance of these safety notes can lead to severe impacts on the health,

with the possibility of life-threatening injuries and extensive material damages.

•Activity that is not allowed to prevent the danger

WARNING

Type and source of danger

This symbol warns of an imminent danger for life and health of persons as well as

of damages to environment and property.

Nonobservance of these safety notes can lead to severe consequences for health

leading to life-threatening injuries or may lead to extensive environment and

property damages.

•Activity that is not allowed to prevent the danger

CAUTION

Type and source of danger

This symbol warns of an imminent danger for the health of persons as well as of

damages to environment and property.

Nonobservance of these safety notes can lead to medium or minor

consequences for health or may lead to extensive environment and property

damages.

•Activity that is not allowed to prevent the danger

UBS Hydro II

Safety EN

2018-05-02 8 / 60

NOTE

Type and source of damage to machine or plant

This symbol warns of a dangerous situation and serves for marking a safety note

referring the dealing with the machine or plant.

Failure to obey these instructions may lead to property damage.

•Activity that is not allowed to prevent the damage to the machine or plant

Hints and recommendations

This symbol highlights useful hints and recommendations as well as information

about efficient and proper operation.

Further signs

For highlighting instructions to act, results, lists, references and other elements, the

following signs are used in these Operating Instructions:

Marking

Explanation

1., 2., 3. ...

Step-by-step instructions for acting

Results of action steps

•

List without specified order

[Button]

Control elements (e.g. push-buttons, switches), indicators

(e.g. signal lamps)

"Display"

Screen elements (e.g. softkeys, assignment of function

keys)

Piktogramme

2.2 Pictograms

Observe the instruction

Use the marked machine only after you have read the instructions.

Wear protective clothing

This sign indicates that protective clothing is to be worn in the respective area.

Protective clothing is close-fitting work clothing with low tear strength and narrow

sleeves and without protruding parts.

UBS Hydro II

Safety EN

2018-05-02 9 / 60

Wear protective shoes

This sign indicates that protective shoes are to be worn in the respective area.

Safety shoes protect your feet from crushing, falling parts and slipping on slippery

floor.

Wear protective gloves

This sign indicates that protective gloves are to be worn in the respective area.

Wear protective gloves to protect your hands from friction, abrasion, punctures,

cuts or deep injuries, as well as from contact with hot surfaces.

Wear safety glasses

This sign indicates that safety glasses are to be worn in the respective area.

Safety glasses shall protect the eyes from particles flying around and splashing

fluid.

Operating Instructions and Safety Instructions

Before commissioning, read and observe the Operating Instructions and the safety

instructions.

Never open or remove the safeguards with the engine running.

UBS Hydro II

Safety EN

2018-05-02 10 / 60

Observe the instructions in the technical Operating Instructions.

Lubrication point!

Only touch any parts of the machine after they have been stopped completely.

Danger due to thrown out parts with the engine running.

Keep a safe distance!

2.3 Intended use

WARNING

Risk of injury / risk damage to environment due to improper use of the

machine!

There is a risk of injury, as well as a risk of damage to environment and material

damages (on the machine or system) due to improper use of the machine!

•The one-axle carrier vehicle as well as the attachments released by the

manufacturer are built for the use für den respective usual or common

application and works in the field of agriculture and forestry, e.g. green

area conservation and premises upkeep as well as for winter service.

•Any other use will be regarded as unintended use. The manufacturer shall

not be liable for damages resulting from this; the risk is borne solely by the

operator.

•The intended use also includes the observance of all operating,

maintenance and servicing instructions prescribed by the manufacturer.

•The one-axle carrier vehicle is only allowed to be used, maintained and

repaired by persons who are familiar with it and have been instructed about

the risks.

UBS Hydro II

Safety EN

2018-05-02 11 / 60

•The applicable accident prevention regulations and the otherwise generally

approved regulations for safety and occupational health must be complied

with.

• Unauthorized changes on the machine cause the manufacturer’s exclusion

of liability for the resulting damages.

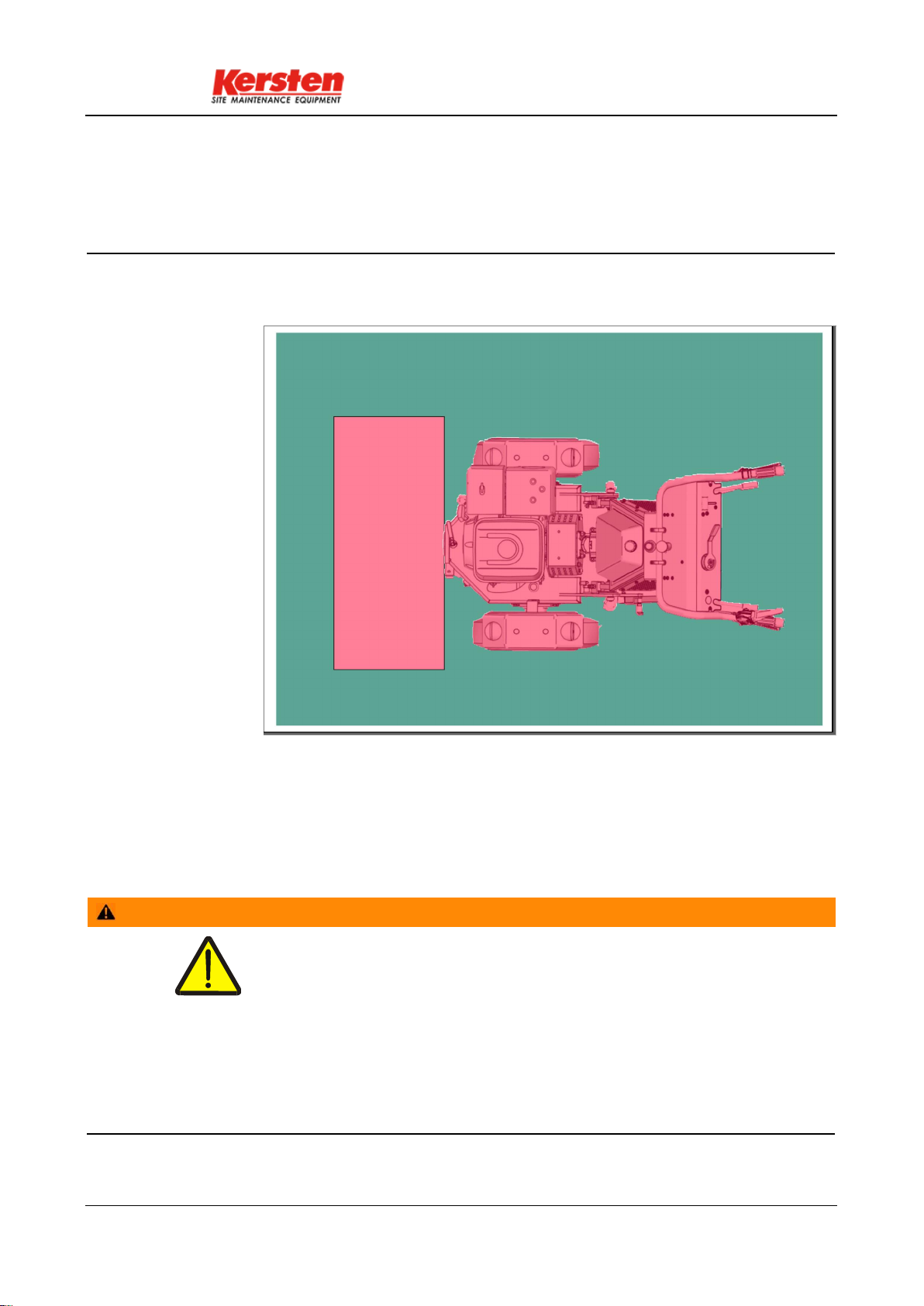

2.4 Work areas and danger zones

Fig. 1: Danger zone (top view)

Basically, the scope of delivery includes the machine as displayed and listed. It

refers to the UBS Hydro series.

•RED Danger zone

•GREEN Work area

WARNING

Risk of injury / risk damage to environment when working / staying within

the danger zone!

There is a risk of injury, as well as a risk of damage to environment and material

damages (on the machine or system) due to improper use of the machine!

•In the danger zone of the machine, the user has to ensure the safety of

third party!

It is not allowed to stay within the danger zone of the machine! Expel all people

from the danger zone.

•If any people approach the danger zone, the machine must be switched

off.

UBS Hydro II

Safety EN

2018-05-02 12 / 60

•The operator has to ensure that no persons or objects are within the

possible discharge area of an attachment.

•Before switching on the attachment and starting up of the machine, check

the danger zone. Mainly pay attention to children and animals. Provide for

sufficient sight!

•In poorly visible areas, switch the attachment off and make sure that

nobody is within the danger zone.

•Before starting work, remove all foreign bodies from the area to be treated.

While working, pay attention to other foreign bodies and remove them early

enough.

•When working in bordered areas, the safety distance to the border must be

kept to prevent the machine from being damaged.

•When working in close vicinity to public roads and paths make sure that the

discharge area is with the work area because there is a risk of injury for

third parties. Therefore, approach the working paths with rotating brushes

in longitudinal direction. If a weed brush is used, approach the working

path in transverse direction.

•When working near or in close vicinity to public roads and places, put up

information and danger signs to draw third parties’ attention.

2.5 Safety during the working process

WARNING

Risk of injury / risk damage to environment due to nonobservance of safety

measures!

There is a risk of injury, as well as a risk of damage to environment and material

damages (on the machine or the host vehicle) due to nonobservance of safety

measures!

•During driving, never leave the place on the steering bar.

•Never change the steering bar during driving.

•Additionally to the instructions in these Operating Instructions also observe

the applicable safety and accident prevention regulations!

•The one-axle host vehicle is not allowed to be operated by persons aged

under 16; this is also forbidden under the supervision of an adult! Children

and young people are to be taught not to play with machine.

•Only instructed personnel or persons are allowed to use this machine!

•When driving on public traffic routes, observe the applicable regulations!

•The one-axle host vehicle is not approved for driving on public traffic roads.

•The operator shall wear tight fitting clothing. Loose clothing is to be

avoided and sturdy shoes or safety shoes must be worn!

•Work only with good sight and light conditions!

•The attached warning and information signs include important instructions

on safe operation; their observance is required for your safety!

•If it is transported on motor vehicles or trailers outside the area to be

treated, switch the engine off!

•Beware of rotating tools - safety distance!

UBS Hydro II

Safety EN

2018-05-02 13 / 60

•Beware of coasting down tools. Before working on these components, wait

until they stopped completely!

•If the attachment is blocked by a foreign body, switch the engine off and

clean the attachment using a suitable tool!

•There are crushing and shearing positions on driven parts!

•It is forbidden to transport people and objects!

•Driving behaviour, steering and possibly braking capability as well as

tipping behaviour are influenced by attached or hooked-up devices and

load. For this reason, only the attachments are allowed to be used that

have been approved by the manufacturer. Adapt the working speed to the

current conditions.

•Do not change the maximum idle speed of the engine. A too high speed

will increase the risk of injury.

•Unauthorised modifications that put operational safety of the machine at

risk are forbidden!

•If the self-propelled working machine or the attachment is damaged,

immediately switch the engine off and get the damage repaired!

•If there is a risk of sliding off in sloping areas, it is required that an

accompanying person secures the host vehicle using a bar or a rope. The

accompanying person has to be above the vehicle at a sufficient distance

from the working tools! The assistant should wear pole climbers.

•Drive across the slope, if possible.

•Under humid and rainy conditions, do not use the machine at the slope.

•On steep slopes, use grid wheels or spike wheels to avoid sliding off.

•In case steering is troubled, immediately stop the self-propelled working

machine and switch the engine off. Immediately eliminate the malfunction.

•Before each commissioning, check the machine for operational safety!

•If the working machine starts sliding down at the slope, immediately let off

the handles.

Coupling and decoupling of attachments

WARNING

Risk of injury / risk damage to environment due to nonobservance of safety

measures!

There is a risk of injury, as well as a risk of damage to environment and material

damages (on the machine or the system) due to nonobservance of safety

measures!

•Observe the relevant instructions and safety instructions of the host

vehicle.

•When changing the attachments and their components use suitable tools

and wear gloves.

•For mounting and demounting place the necessary supports in the

respective position and provide for sufficient stability.

•Secure the self-propelled working machine and the attachment against

rolling away (locking brake, chocks).

UBS Hydro II

Safety EN

2018-05-02 14 / 60

•There is a risk of injury when the attachments are coupled (crushing).

Special attention is required.

•Couple the attachments correctly and fasten them in the specified

positions.

2.6 Safety equipment

DANGER

Danger to life and limb due non-functioning safety devices!

Non-functioning or overridden safety devices can result in danger to life and limb.

•Verify if the safety equipment is fully functional and installed correctly

before start of operation.

•Never override or bridge the safety equipment.

•Ensure that all the safety equipment is always accessible.

2.6.1 Emergency shut-down via the dead man lever

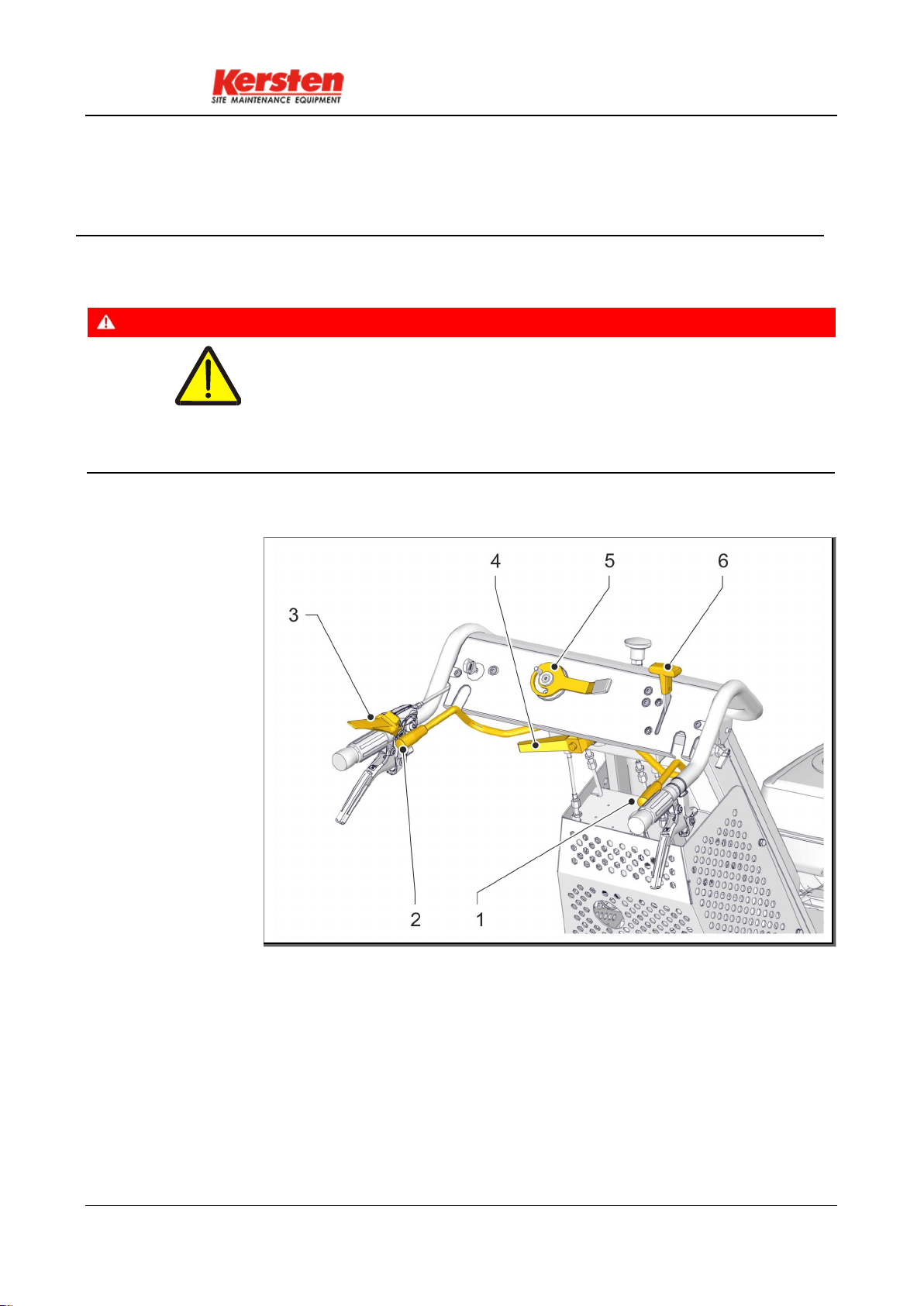

Fig. 2: Dead man lever

1 Drive lever, right

2 Drive lever, left

3 Dead man lever

4 Adjustment lever

5 Auxiliary drive

6 Throttle lever

UBS Hydro II

Safety EN

2018-05-02 15 / 60

In an emergency, immediately release the two handles of the operating unit. With

this, the dead man lever (3) triggers.

•The one-axle host vehicle stops

•The drive to the attachment is interrupted

•The engine will NOT be switched off and continues running

Before moving off, perform the following steps!

•Drive lever (1, 2) must be in horizontal position.

•The lever for the auxiliary drive (5) must be switched in the „Off“ position.

•Push the dead man lever (3) down.

If only one of the before mentioned conditions is not fulfilled, moving off / switching

on of the auxiliary drive will NOT be possible despite of the actuation of the dead

man lever (3).

2.7 Safety signage

The following symbols and indicating labels are in the work area. They refer to the

immediate vicinity where they are attached.

WARNING

Risk of injury due to illegible or missing signage!

Missing or illegible Labels and signs can lead to severe health impairment and

potential life-threatening injuries.

•Keep all safety, warning and operating indications al-ways in a good legible

state.

•Exchange immediately damaged signs and stickers.

2.8 Residual risk

The machine is designed according to the state of the art and the actual safety

requirements. However, there are still residual risks that require cautious acting.

The residual risks and the corresponding behavior and measures are listed below.

Improper transportation

NOTE

Material damages due to improper transportation

Pieces been transported can fall or tumble if transported improperly. This can

cause considerable material damages.

•Work carefully when unloading the transport pieces upon delivery as well

as when transporting within the factory and pay attention to the symbols

and instructions on the packaging.

•Use only the attachment points provided.

•Remove the packaging only just before assembly.

UBS Hydro II

Safety EN

2018-05-02 16 / 60

Dirt and scattered objects

CAUTION

Risk of injuries due to falling over dirt and objects lying around!

Dirt and scattered objects are the reasons for slipping and tripping hazards.

Falling may result in personal injuries.

•Always keep the work area clean.

•Remove objects that are not required anymore from the work area,

especially near the floor.

•Remove the tools or components from the work area.

Cleaning agent

WARNING

Risk of injury due to improper use of cleaning agents or substances

Improper use of cleaning agents or substances can have severe consequences

for health leading to life-threatening injuries.

• Read the material safety data sheets and the manufacturer’s instructions

applicable for the cleaning agents or substances

•Wear your appropriate personal protective equipment (e.g. gloves, safety

shoes, protective suit, protective mask safety glasses, etc.)

•Provide for sufficient ventilation of the environment

•Use caution when handling hot cleaning agents or substances. Touching

can cause burns and scalding

•If necessary, clean parts, assemblies, or components from sticking grease

and other pollution

•Avoid skin contact with cleaning agents or substances

•Do not inhale vapour caused by cleaning agents or substances

•Keep it away from naked flames and do not smoke

Noise level

Applicable noise-abatement regulations and warning signs in the complete

documentation must be observed as well. The noise level on site depends on the

local background noise. The user must check the noise level regularly.

WARNING

Risk of injury due to noise!

The noise level occurring in the working area may cause serious hearing

impairment.

•Do not remove covers, insulating materials, and other insulating parts of

the machine and replace them if damaged.

•If the daily noise exposition level exceeds 85 dB(A), in this case the user of

the machine must instruct the operators to wear hearing protection.

•Stay within the danger zone only when it is necessary.

UBS Hydro II

Safety EN

2018-05-02 17 / 60

Moving parts

DANGER

Danger to life and risk of injury due to moving parts!

There is danger to life and a risk of injury, as well as a risk of material damage to

the machine or system due to improper dealing with moving parts

•Do not reach into moving parts or manipulate moving parts during

operation.

•Do not open the coverings during operation.

•Pay attention to the after-run time: Before opening the coverings, make

sure that there are no parts still moving.

•Within the danger zone, wear tight fitting protective clothing with low tear

strength.

Sharp edges and corners

CAUTION

Risk of cutting due to sharp edges and corners!

Sharp edges and corners can cause excoriation and cuts of skin.

•Be careful when working near sharp edges and corners.

•If in doubt, wear protective gloves.

Hydraulic system

DANGER

Danger to life and risk of injury due to hydraulic energies!

There will be danger to life or a risk of injury due to hydraulically driven

components.

•Only qualified hydraulic specialists are allowed to work on the hydraulic

system.

•Do not reach into moving parts or manipulate moving parts during

operation.

•Do not open the coverings during operation.

•Within the danger zone, wear tight fitting protective clothing with low tear

strength.

Operating agents / consumables / lubricants / oils

WARNING

Risk of injury due to improper use of operating agents or substances!

Improper use of operating agents or substances can have severe consequences

for health leading to life-threatening injuries.

• Read the material safety data sheets and the manufacturer’s instructions

applicable for the operating agents / substances

UBS Hydro II

Safety EN

2018-05-02 18 / 60

•Wear your appropriate personal protective equipment (e.g. gloves, safety

shoes, protective suit, protective mask safety glasses, etc.)

•After unintended eye contact flush your eyes thoroughly with much water

and consult the doctor.

•After contact thoroughly wash your skin with much water.

•Provide for sufficient ventilation of the environment

•Use caution when handling hot operating agents or substances. Touching

can cause burns and scalding

•If necessary, clean parts, assemblies, or components from sticking grease

and other pollution

•Avoid skin contact with operating agents or substances

•Do not inhale vapour caused by operating agents or substances

•Keep it away from naked flames and do not smoke

2.9 Environment protection

WARNING

Environmental hazard by wrong handling of environmentally hazardous

substances!

When handling environmentally hazardous substances wrong, especially when

they are disposed of incorrectly, considerable environmental damages may

occur.

•Read the Material Safety Data Sheets and the manufacturers' instructions

for operating resources or substances as well as for cleaning agents or

substances

•Store water and ground hazardous operating resources or substances,

such as oil-contaminated parts, assemblies or components in secured

areas or collecting trays

•Bind leaked operating resources or substances as well as for cleaning

agents or substances with a binder and dispose it according to local

regulations

•If necessary, clean parts, assemblies or components from adhering oil,

grease and other contaminants

•Do not let drains operating resources or substances as well as cleaning

agents or substances into soil or canalization

The following environmentally hazardous substances are used:

Lubricants

Lubricants like grease and oil contain poisonous substances. They must not get to

the environment. The disposal has to be done by a professional disposal company.

Oils

Oils (e.g. lubrication-, hydraulic- or cleaning oils) must not get to the environment.

Oils causes long-term environmental damages in waters. The disposal has to be

done by a professional disposal company.

Observe the safety data sheets of the manufacturer.

UBS Hydro II

Safety EN

2018-05-02 19 / 60

Electronic components

Electronic components may contain poisonous substances. They must not get to

the environment. The disposal has to be done by a professional disposal company.

Accumulators and batteries

Rechargeable batteries contain toxic heavy metals. They are subject to special

treatment and must be returned to municipal collection points or disposed of by a

specialist.

2.10 Safety instructions for maintenance / trouble shooting

Conduct in case of dangerous faults

The following applies:

1. Initiate the emergency stop immediately in case of faults that represent an

immediate risk for persons or objects.

2. Determine the cause of fault.

3. In case rectification of the fault requires work to be done in the danger zone,

switch off the machine and secure it against a restart.

4. Depending upon the type of fault, get it rectified by authorized specialist

personnel or rectify it yourself.

DANGER

Risk to life or risk of injury due to improperly carried out maintenance work

/ trouble shooting!

Maintenance work / trouble shooting conducted improperly causes danger to life

or risk of injury, as well as risk of material damages to the machine or system!

•Observe all safety instructions in this chapter as well as the applicable

local safety and accident prevention regulations

•Malfunctions, which require an intervention, as well as maintenance and

cleaning works, should be rectified only when it is ensured that the

machine is at a standstill and is safeguarded against a restart.

•Release the blockages only when it is ensured that removing them will not

result in any dangerous movements of machine parts.

•Ensure adequate freedom of movement before starting the work.

•Pay attention to order and cleanliness at the assembly place! Parts lying

around loose or one above the other are sources of accidents.

- If components have been removed, pay attention to correct assembly,

reassemble all fixing elements.

•Pay attention to the following before a restart:

•Make sure that all works have been done and completed according to the

instructions and information given in these Operating Instructions.

•Ensure that no persons are present in the danger zone.

•Make sure that all coverings and safety devices are installed and are

working properly.

•Wait until the oil has cooled down below 50 °C, before starting works

•Before starting works, make a temperature-resistant collecting container

with the necessary capacity available.

UBS Hydro II

Safety EN

2018-05-02 20 / 60

WARNING

Risk of injury / risk damage to environment due to poor / missing

maintenance!

There is a risk of injury, as well as a risk of damage to environment and material

damages (on the machine or the system) due to poor maintenance!

•Only perform maintenance and cleaning works when the engine stands

still.

•When working on the engine, generally pull the spark plugs off.

•The operating personnel are allowed to perform simple cleaning and

adjusting works. Maintenance and service works are only allowed to be

done by instructed specialist personnel.

•Observe the instructions given in the original Operating Instructions of the

subcontracted parts.

•If safeguards and tools are subject to wearing, they have to be checked

regularly and replaced, if necessary.

•For the replacement of cutting tools use the appropriate tool and suitable

protective equipment.

•After maintenance and cleaning works, it is definitely necessary to remount

the safeguards and to place them in their protecting position!

•Only use original spare parts from the manufacturer because these meet

the technical specifications and with this, the risk of accidents will be

minimised!

•Cleaning works with the high-pressure cleaner should be done in a way

that the water jet does not directly meet the bearing, rotating parts,

lubricating nipples, shaft sealing rings, wheel hubs, etc. After each cleaning

procedure with the high pressure cleaner, the lubricating points must be re-

greased. If this is not observed, the warranty claim will be rendered null

and void!

•After 5 operating hours and then regularly, check the screws and nuts for

tight fit and retighten them, if necessary.

•After maintenance mount the safeguards and place them in their protecting

position.

•If the machine is maintained, cleaned, or repaired in a raised position,

always secure it by suitable supporting elements.

When working on the electrical system, the earth strap must be removed from the

battery.

•If welding works are done on the machine, disconnect the battery.

•Repair works like welding, drilling, grinding, etc. may not be done on load-

bearing, safety-related parts.

•Before starting any repair works, make sure that the hydraulic system has

been depressurised, because pressurised fluids can penetrate skin and

cause serious injuries! Therefore, immediately consult a doctor - risk of

infection!

•Check hydraulic connections after 5 operating hours for the first time,

retighten if necessary!

Only re-tightening is not successful!

First release a leaky hydraulic screwed connection, then move hose or screwed

connection. After that, the screwed connection can be tightened again.

Table of contents

Other Kersten Lawn Mower manuals