-3-

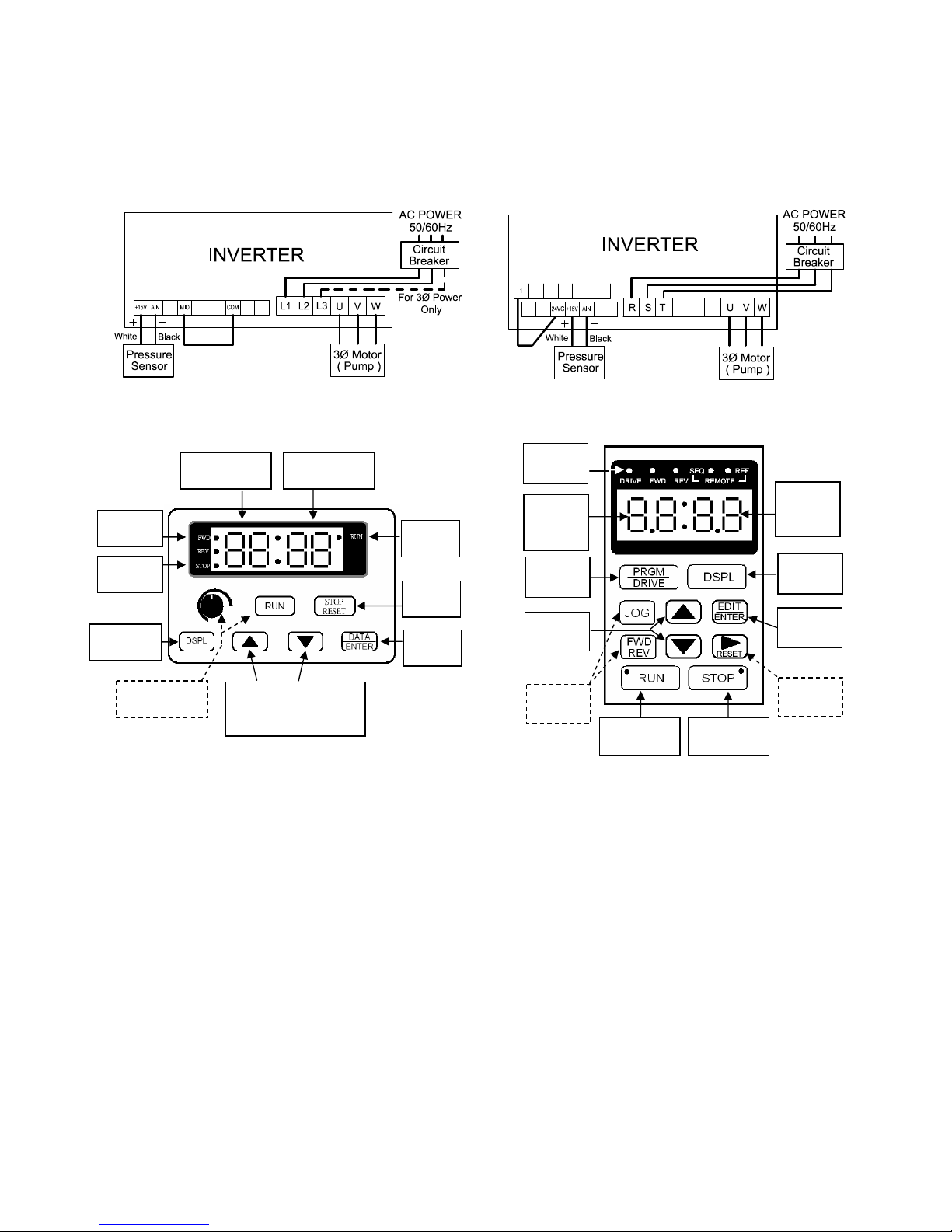

§ ELECTRICAL CONNECTION!

1. Every installation requires an accessible

appropriate rated circuit breaker for future

maintenance. Leakage circuit breaker is also

required in the environment with high humidity.

2. Verify that the supply power voltage and HZ

match the inverter input requirements.

Electrical wiring shall be done in accordance

with the local electrical code by a competent

electrician.

!

!

3. The motor/pump will enter the running mode

automatically after the power ON. For any

failures caused by abnormal electrical power

supply, reset the inverter (disconnect the power

at least 1 minute, for the inverter LED display

off), and then set the power ON.!

4. Good ventilation for the control box is important

to prevent the overheating of inverter and

resulting failures.!

!

§ OPERATION PROCEDURE

1. Pump must be primed by feeding the pump

casing and suction pipe with water before

starting the pump to avoid damage of pump

parts, especially the mechanical seal.

◎For the pump with water supply above the

pump level, remove the pump priming plug,

and put it back securely when the water

overflow from pump priming hole. Vent any

air trapped in supply pipe or casing by

opening the valves in discharge pipe.

◎For the pump with water supply below the

pump level, remove the pump priming plug,

and fill the pump and suction pipe with

water. Any air trapped in suction pipe and

casing must be removed.!

2. Insert a screwdriver into motor shaft end, and

turn the shaft several turns clockwise to check

whether the pump can be rotated freely. If not,

disassemble and clean the pump chamber.

3. Double check the voltage and wiring of the

motor power and then turn the power switch ON.

Open faucet or water appliances on the

discharge piping side. The water should be

delivered after several seconds.

4. If the water does not be delivered after several

minutes, turn off the pump immediately. Repeat

step 2 to pour water into the pump and suction

piping, and switch power ON and OFF

continuously.

5. Once the water is pumped out, close and open

the water appliances on the discharge side

repeatedly to check automatic ON/OFF

operation.

6. When re-start the pump after long term shut

down, please repeat step1~5 to ensure the

normal operation.

§ OUTPUT HEAD SETTING

!

!

!

!

!

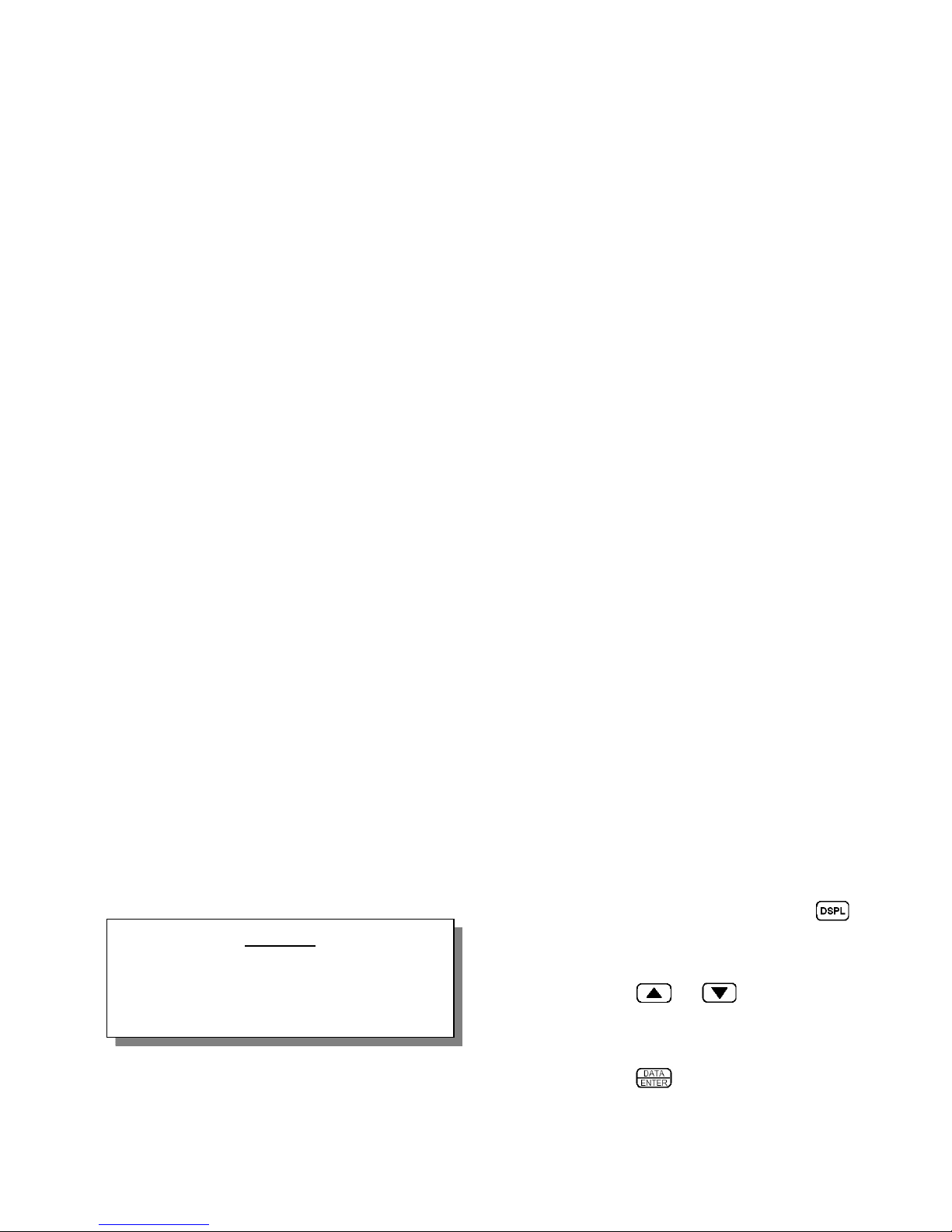

¾Step 1ĈMake sure that the inverter display is in

“Head Mode”. If not, press

key continuously until the “Head

Mode” is displayed.

¾Step 2ĈPress or continuously to

adjust the “Setting Head” shown on

the right screen Ą

¾Step 3ĈPress to save the setting.

!

CAUTION

Improper pressure setting will cause pump

failure. Pressure setting too high will fail to stop

while too low will fail to start.