www.kimray.com

GLYCOL PUMP

4

Repair Guide

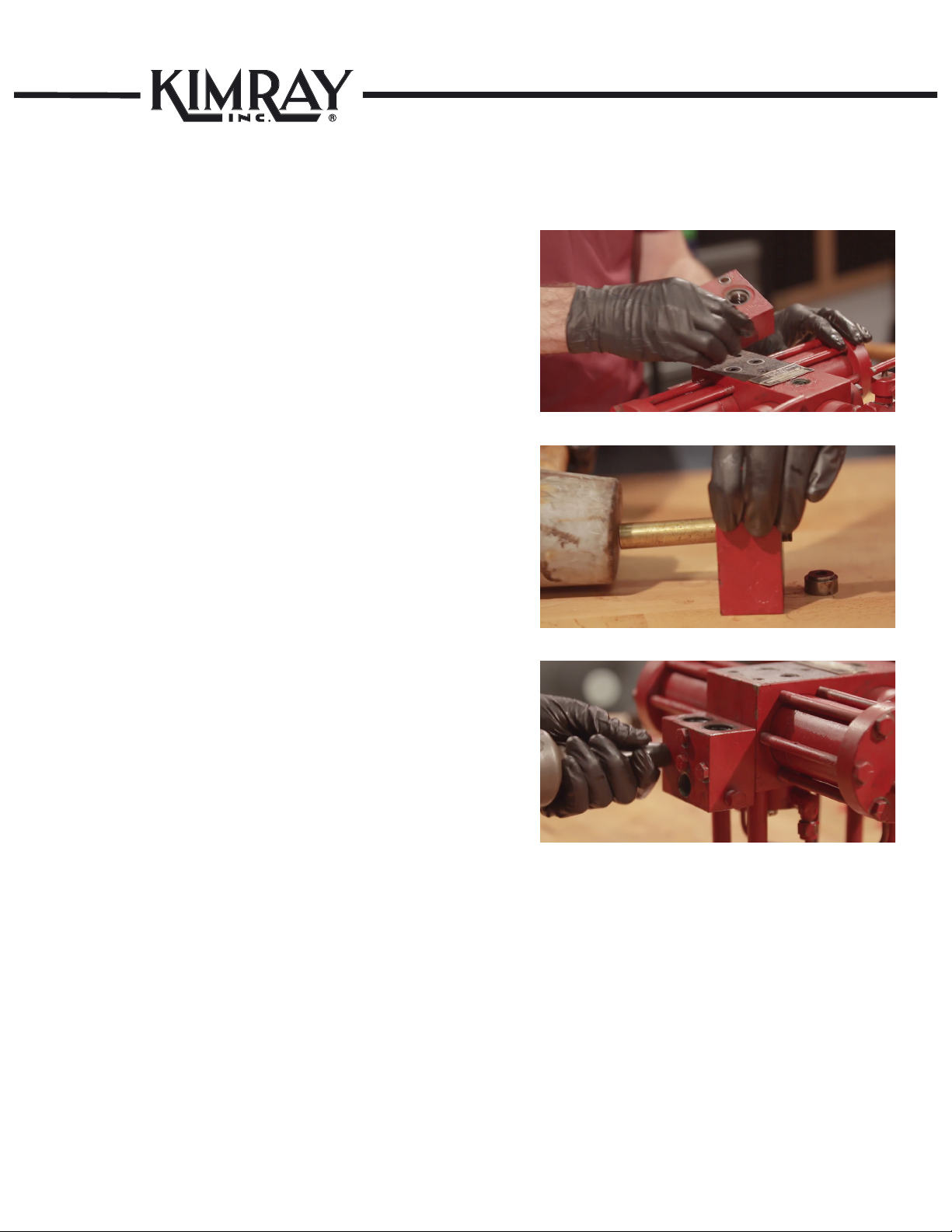

When a person needs to repair a Kimray glycol pump

and has never done so before, it can appear to be the

proverbial “can of worms” when it is disassembled and the

many parts and O-Rings are exposed. Even with a parts

drawing, it can be intimidating.

Nothing is as good as experience and hopefully, this

repair manual will help simplify the process. Years of

valuable experience was used to put together this manual

that details the disassembly, the examination of parts, and

the assembly of the Kimray Glycol Pump.

If these steps are followed, the pump should be “as good

as new” and ready for service. Also after going through

this manual, it will be easy to see why only replacing the

O-Rings will probably not give any acceptable length of

service.

There are typically four areas that can cause pump failure.

INTRODUCTION

I. GLYCOL CONTAMINATION

This can be caused by various things such as compressor

oils carrying over into the glycol that may cause O-Ring

swelling. Condensate (drip gas) can be another. If glycol

contamination is a constant and uncorrectable problem,

there are other elastomers available.

II. HEAT

The Kimray Glycol Pump comes standard from the factory

with Buna elastomers good for up to 200 degrees F.

Heat exchangers are essential in a dehydrator system

so that the dry glycol entering the pump is less than 200

degrees to prevent breaking down the elastomer. This

also enhances the dehydration process.

However, if there are continuing temperature related

failures, there are other materials available for elastomers

that will allow the pump to be used in higher temperatures.

III. FILTRATION

A “Y” strainer or other LOW PRESSURE filter is

recommended in the “dry” or “lean” suction line coming

from the surge (storage) tank to the pump. This will

catch any large particles that might cause the pump to

malfunction or damage it.

A HIGH PRESSURE filter is recommended in the “wet” or

“rich” glycol line coming from the bottom of the absorber

to the pump. There are several manufactures and types

of these filters.

This filter will catch smaller particles suspended in the

glycol such as salt and sand.

All filters need to be checked frequently and changed if

needed.

IV. IMPROPER REPAIR

Even with filtration, parts within the pump will wear over

time. Metal parts need to be examined very closely every

time a repair is done. Worn metal parts can cause lost

tolerances and therefore cause lost seals. Replacing

O-Rings ONLY , usually will not give long service. Piston

rod, pilot piston, cylinder, and piston surfaces are critical.

Anywhere there is an O-Ring surface should be checked

closely.

To get the long service you have come to expect from

Kimray products, always use genuine Kimray parts

when doing repairs. Remember, parts made to less than

Kimray specifications don’t save you money!