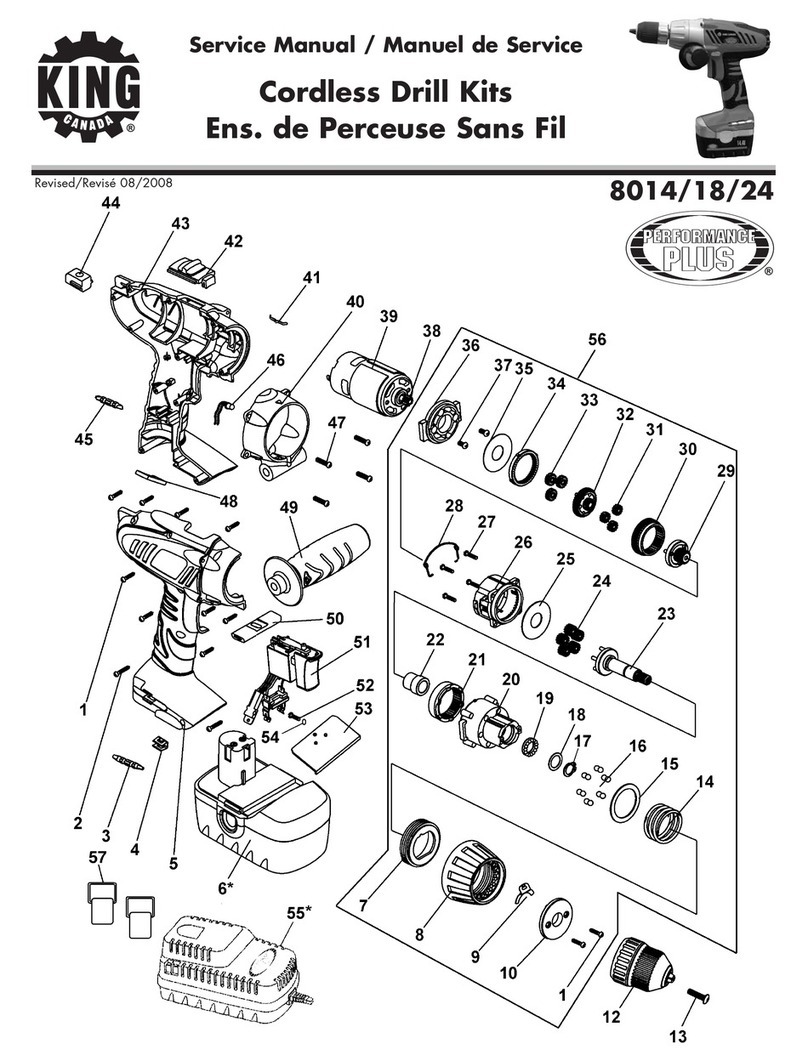

GETTING TO KNOW YOUR HAMMER DRILL

A. Trigger

B. Forward /reverse switch

C. Chuck

D. Variable speed control

E. Lock-on button

F. Hammer mode switch

G. Depth stop gauge

FIXING & CHANGING DRILL BIT

•Turn the Hammer Drill off first.

•Clean the shivers and any other foreign objects away from the bit and chuck, otherwise

the bit might not be tightened securely and thus will induce severepersonal injuries.

•Insert the bit into the chuck, make surethat the bit

is in as far as it will go.

•Place the chuck key in one of the 3 holes, then

tighten all three jaws of the chuck by rotating the

chuck key clockwise.

WARNING:More than 1/3 of the general length of

the drill bit must protrude out of the chuck jaws.

•When dismantling the drill bit, loosen the three jaws with the chuck key, then remove the

drill bit.

NOTE:Always remove chuck key before restarting drill.

SWITCH ACTION

WARNING:Beforepluging into power source, make surethe trigger switch can be

pressed down smoothly and will return to its “OFF” position when the switch button is

released. The drill is equipped with a “Lock-On” button which is convenient when

continuous drilling for extended periods of time is

required.

•Press down trigger switch to start work, and release to

stop work.

• To have continuous operation, press down the trigger

switch and push the “Lock-on” button located on the

side of the handle, then release the trigger.

•The drill will continue running after the release of the “Lock-on” button. Tostop

working, release the trigger switch.

•When “Lock-on” feature engaged during use and the drill becomes disconnected from

the power supply, disengage the “Lock-on” feature immediately.

OPERATION OPERATION

REVERSIBLE ROTATING DIRECTION

The rotating direction of the drill is controlled by a lever

located above the trigger.

•With the drill held in normal operating position, direction

of rotation lever should be positioned to the right of the

trigger for forward (F) drilling operation.

•Direction of rotation is in reverse (R) when the lever is to

the left of the trigger.

NOTE: The drill will not operate unless the rotation lever is pushed fully to the left or right.

SPEED CONTROL

The drill can be preset to match material requirements by

using speed control selector.

•Hold the drill in normal operation, and turn the variable

speed control selector clockwise to increase the speed

and torque of the drill. Turn counter-clockwise to

decrease the speed and torque.

NOTE: If the variable speed control selector is fully turned

in counter-clockwise direction (Zero Setting), Your drill may not run.

• To lock the switch on at a given speed, depress the trigger, push in and hold the

“Lock-on” button then release the trigger.Next, adjust the variable speed control

selector until the desired speed is reached.

•When you desirenot to use the variable speed control selector turn it in the fully

clockwise direction. This will allow the speed of the drill to be fully controlled by the

amount of trigger depression.

•Speed control guidelines:

1) Low speed - is ideal when minimum speed is required. e.g.: Making holes without

center punch, driving screws, mixing paint or drilling ceramics.

2) Medium speed - is suitable for drilling hardmetals, plastics and laminates.

3) High speed - Perfect for when maximum power is required. E.g.: Drilling in wood, soft

metals like aluminum, brass or copper.

WORKING MATERIALS

The working materials should be within: “wood, metal, resin boards, concrete”.

•When drilling hard, smooth surfaces, use a center punch to mark the desired hole

location. This will prevent the drill from slipping offcenter as the hole is started.

•The working material should be secured in a device or with clamps to keep it from

moving as the drill bit rotates.

•When drilling concrete and masonry, move the function changeover device to “hammer

icon”. Toachieve the maximum impact when drilling into maconry.

F

R