Pole Pruner/ Palm Harvester

KK-PP2-8627/ KK-PH2-215

: www.kisankraft.com : info@kisankraft.com : +91.80.22178200

Page 10 of 56

22. Do not use the unit when you are tired, ill or under the influence of medication,

drugs or alcohol.

23. FOLLOW INSTRUCTION FOR CHANGING ACCESSORIES.

Do not store in a closed area where fuel vapors can reach an open flame

from hot water heaters, heaters, furnaces, etc. Store in a locked, well

ventilated area only.

Ensure safe and proper performance of your product. Use genuine spare

parts provided by our company.

The use of any other accessories or attachments may cause a potential

hazard or injury to the user, damage to the machine and void this warranty.

24. Clean the machine completely, especially, the fuel tank, its surroundings, and the

air cleaner.

25. When refueling, be sure to stop the engine and confirm that it is cooled down.

Never refuel when the engine is running or hot. When gasoline spills, be sure to

wipe it up completely and properly dispose of those materials before starting the

engine.

26. Whenever approaching an operator of the machine, carefully call his attention

and confirm that the operator stops the engine. Be careful not to distract the

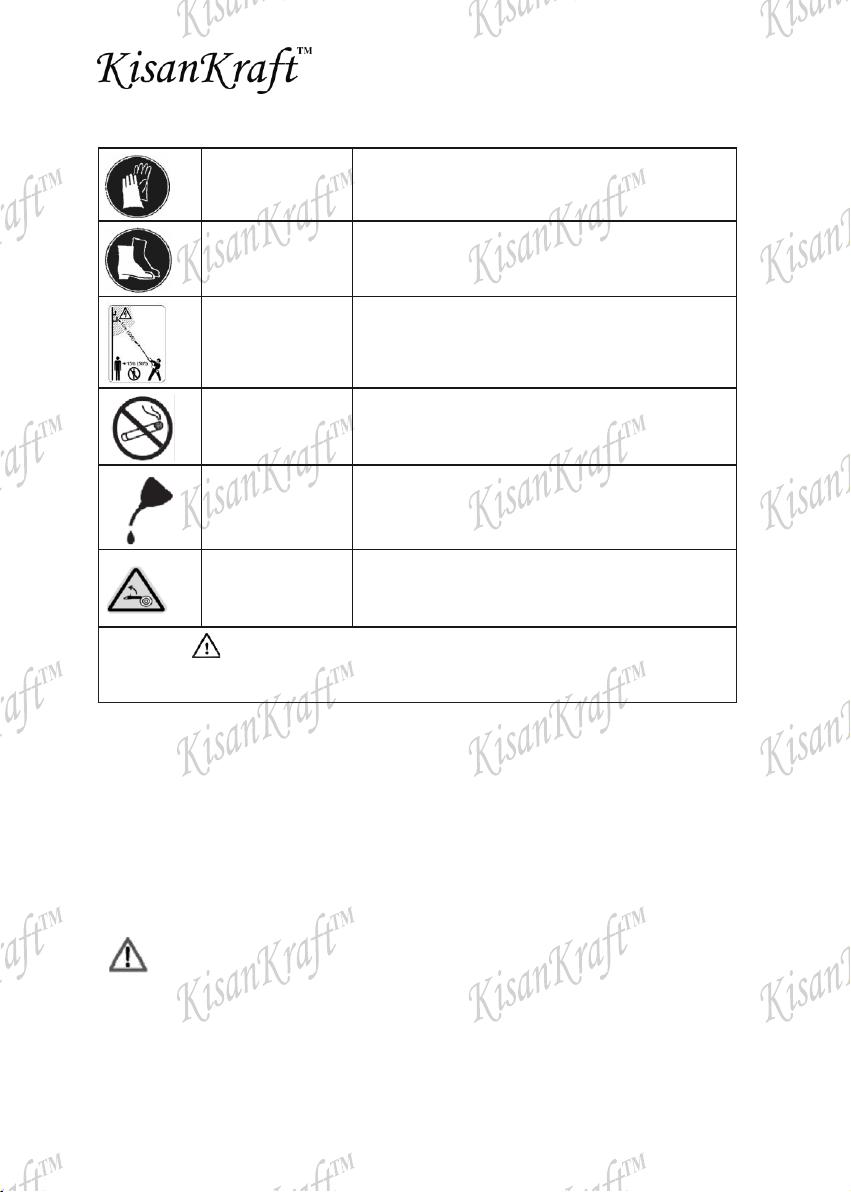

operator which can cause an unsafe situation.

27. Pay attention to loosening and overheating of parts. If there is any abnormality of

the machine, stop operation immediately and check the machine carefully. If

necessary, have the machine serviced by an authorized dealer. Never continue

to operate a machine which may be malfunctioning.

28. In start-up or during operation of the engine, never touch hot parts such as the

muffler, the high voltage wire or the spark plug.

29. This power tool should be carried only in a horizontal position. Grip the shaft in a

manner that the machine is balanced horizontally. Keep the hot muffler away from

your body and the cutting attachment behind you. Accidental acceleration of the

engine can cause the chain to rotate and cause serious injuries.

30. Always switch off the engine and fit the

scabbard over the cutting attachment

before transporting the power tool over

long distances. When transporting it in a

vehicle, properly secure it to prevent

turnover, fuel spillage and damage to

the unit.

31. After the engine has stopped, the muffler is still hot. Never place the machine in

any places where there are flammable materials (dry grass, etc.), combustible

gases or combustible liquids.

32. Pay special attention to operation in the rain or just after the rain as the ground

may be slippery.

33. If you slip or fall to the ground or into a hole, release the throttle lever immediately.

34. Be careful not to drop the machine or hit it against obstacles.

35. Before proceeding to adjust or repair the machine, be sure to stop the engine and

detach the spark plug cap from the spark plug.

36. When the machine is placed in storage for a long time, drain fuel from the fuel

tank and carburetor, clean the parts, move the machine to a safe place and

confirm that the engine is cooled down.