UNCONTROLLED WHEN PRINTED K35-TCR104-07

REV. E, JUNE 2023

5

Table of Contents

Service Request...................................................................................................................................................4

Spare Parts Request.............................................................................................................................................4

Use of this Manual..............................................................................................................................................4

1.0 GENERAL DESCRIPTION............................................................................................................................7

1.1 Compressor..................................................................................................................................................7

1.2 Chiller..........................................................................................................................................................7

1.3 Glycol Components & System.....................................................................................................................7

1.4 Refrigeration System & Components..........................................................................................................8

1.5 Heaters (if equipped)....................................................................................................................................9

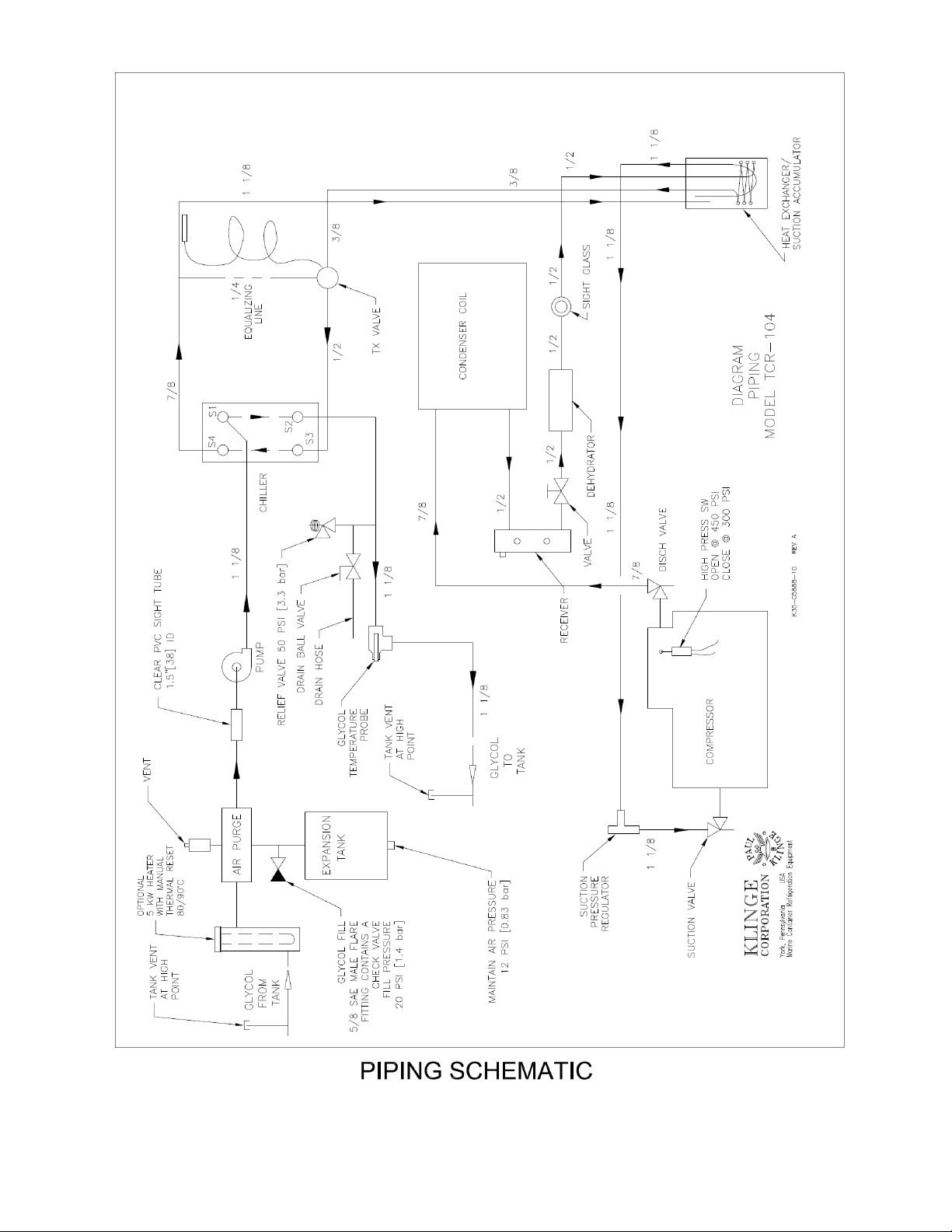

1.6 Piping Schematic.......................................................................................................................................10

2.0 OPERATION.................................................................................................................................................11

2.1 Pre-starting Check......................................................................................................................................11

2.2 Starting Check............................................................................................................................................11

2.3 Running Unit..............................................................................................................................................11

3.0 ELECTRICAL FUNCTIONS.......................................................................................................................15

3.1 General Information (Refer to Electrical Schematic)................................................................................15

3.2 Electrical Box.............................................................................................................................................15

3.3 Electrical Schematic...................................................................................................................................17

4.0 MICROPROCESSOR THERMOSTAT........................................................................................................19

4.1 General Information...................................................................................................................................19

4.2 Display Panel.............................................................................................................................................19

4.3 Temperature Sensors..................................................................................................................................21

4.4 Microprocessor Thermostat and Data logger.............................................................................................21

4.5 Microprocessor Control Sequence/ Functionality......................................................................................22

5.0 MAINTENANCE AND SERVICE INSTRUCTION...................................................................................27

5.1 General.......................................................................................................................................................27

5.2 Safety.........................................................................................................................................................27

5.3 Checking Refrigerant Charge.....................................................................................................................28

5.4 Procedure for adding refrigerant................................................................................................................28

5.5 Non-condensable gases..............................................................................................................................29

5.6 Opening the System...................................................................................................................................29

5.7 Testing for Leaks.......................................................................................................................................29

5.8 Evacuating the System...............................................................................................................................30

5.9 Glycol System............................................................................................................................................30

5.10 PTI Form..................................................................................................................................................37