To Edit and Splice Tape

NOTE: It isimpossible to editand spliceone trackof

tape without affecting the second track, therefore re-

cordings to be edited should be iimited to one track

only.

1. Tape recordings may be edited by cutting out

unwanted sections, or by joining selections into another

sequence. Announcements can be inserted between

selections etc. Unused sections of tape can be spliced

together for reuse.

2. For best results cut tape on a slight diagonal,

join ends together with splicing tape on the glossy side

and trim off any excessive width.

Erasing Recorded Material

When the "Record" button is depressed, the

erase head is positioped automatically erasing any pre-

vious recording before a new one is made. Material

no longer needed may be erased without recording by

depressing the "Record" button and turning the 'Yol-

ume" control to the minimum, (or extreme counter-

clockwise position). Only one track is erased at a

time. To erase the second track reverse the reels

and repeat the above operation.

To Use Recorder As a Public Address System

Insert the microphone plug into the "Microphone"

jack. Plug in an extension speaker and depress the

"Record" button. Set the "Tone" and "Volume" con-

trols to the desired level. A recording can be made

at the same time by placing a tape on the unit in the

normal manner.

NOTE: When using the public address feature keep

themicrophone as laraway from thespeakers aspos-

sible to prevent 'Teedback" squeal.

ADJUSTMTNTS

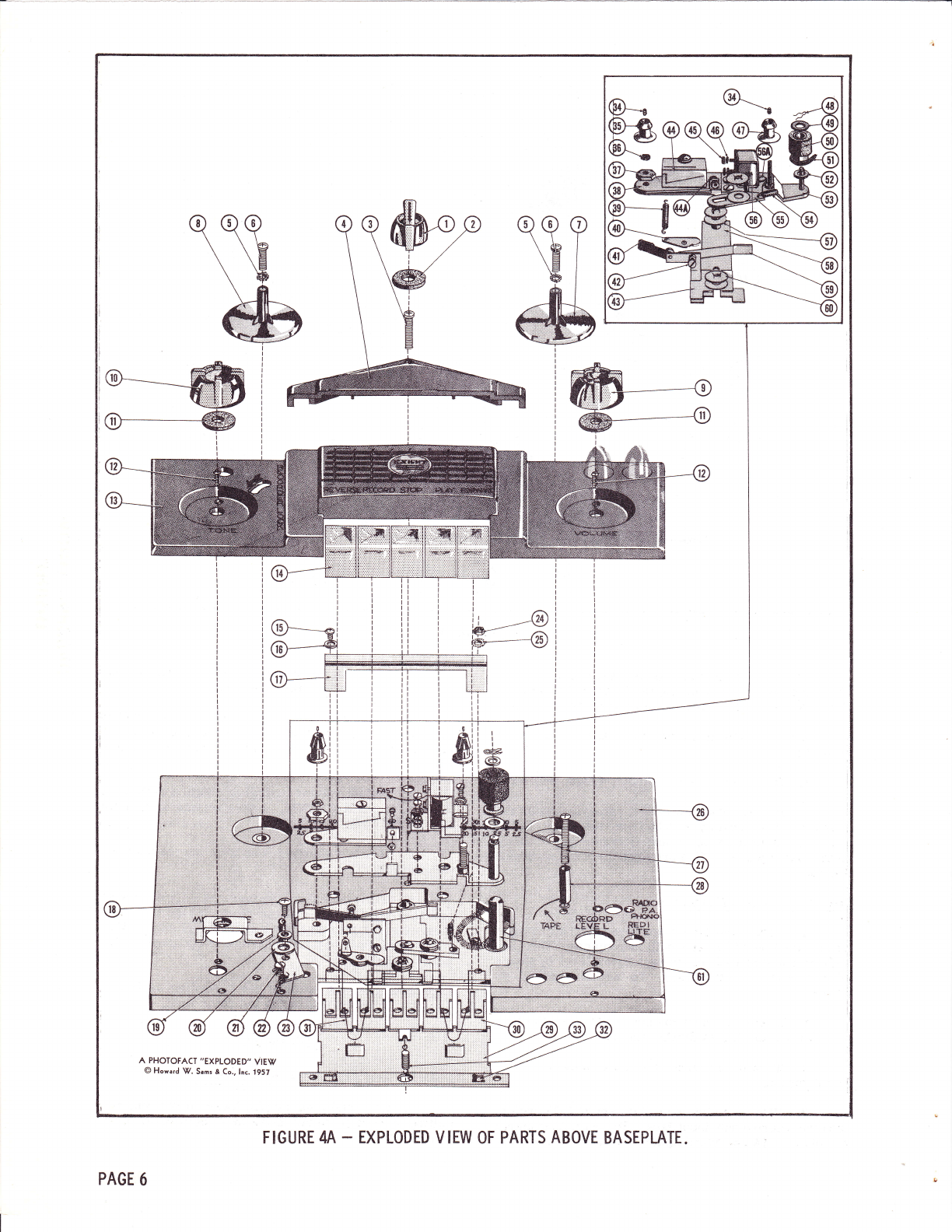

Record-Play Head Adjustment

WFor maximum frequency response, adjust the

record-play head (56) as follows;

l. Remove the rear escutcheon (4).

2. Thread an alignment tape or good recorded

tape in the usual manner.

3. Set the controls as described under I'To Play

Recordings".

4. With the unit playing turn head adjustment

screw (56A) clockwise or counter-clockwise until

maximum high frequencies are obtained.

Pressure Pad AdJustment

@1. Remove the front escutcheon (13).

2, Depress the "Play[ button, Do not turn the

recorder on.

3, Using a pencil type postal scale, check the

amount of pressure necessary to just pull the pad

PAGE 4

away from the tape. The test should be made on the

end of the pressure pad mounting spring (59). Adjust

the pressure pad for I 3/4 oz. + I/4 oz. pressure as

follows:

(a) Therecord headpressurepad isadjusted

by the locked adjustment screw (42).

(b) Tne guide postpressure pad(al)bybend-

ing the pressure pad spring. It must be adjusted for

minimum pressure against the tape.

4, After the adjustments are completed de-

press the "Stop"button and replace the frontescutch-

eon.

Erase Head Adjustment

l. With tape properly threaded, turn recorder

on and depress the "Record"button. Allow tapetorun

a few seconds then turn recorder off, but leave the

"Record" button depressed.

2. With the escutcheons (4) and (13) removed

check the erase head (44)to see if it is paraliel tothe

tape. 3. Check to see if the top edge of the tape coin-

cides with the top end of the diagonai slot in the erase

head (junction of the diagonal slot and short vertical

slot). To adjust level of tape, loosen set screw (34),

(exploded view), and rotate tape guide post (35) to move

tape up or down to correct height. Tighten set screw

(34).

4. After this adjustment has been made, gheck

to see if tape movesforwardapproximatelyl/64" when

the "Record" button is depressed. If not, loosen the

forward adjustment screw (44A), exploded view, and

turn the screw in or out as required to obtain 1,/64"

movement. Tighten the locknut. Replace escutcheous.

Brake Shoe Adjustment

i. Toadjustthebrakeshoes thecompletemech-

anism must be removed from the carrying case, and

the speaker disconnected.

2. With aU push buttons in the up position the

brake shoes (99A) should clear the drums by approxi-

mately 1,/ 8".

3. Depressthe "Stop'tbuttonwhile observingthe

brake shoes. Both brake shoes must contact the drums

at the same time and with equal pressure.

4. Adjust by bending spring arm (99).

Adjustment for Slow Take-Up Reei

l. Occassionally the spring drive belt (51)

stretches after a period of time. This results in in-

sufficient drive torque to wind the tape properly on

the take-up reei. Replace belt as follows:

(a). Remove rear escutcheon(4) and take-up

reet pan (?). Depress the "Stop" button and remove

old belt from around the pressure roller (50). Lift

clear of recorder. Install new belt by reversing the

above procedure.

Bias Adjustment

The bias voitage can be checkedwithout dismantl-

ing the unit by connecting a VTVM across the top lug