8

5603 882 - 01

Pyrotec Installation & Operating

Boiler Description

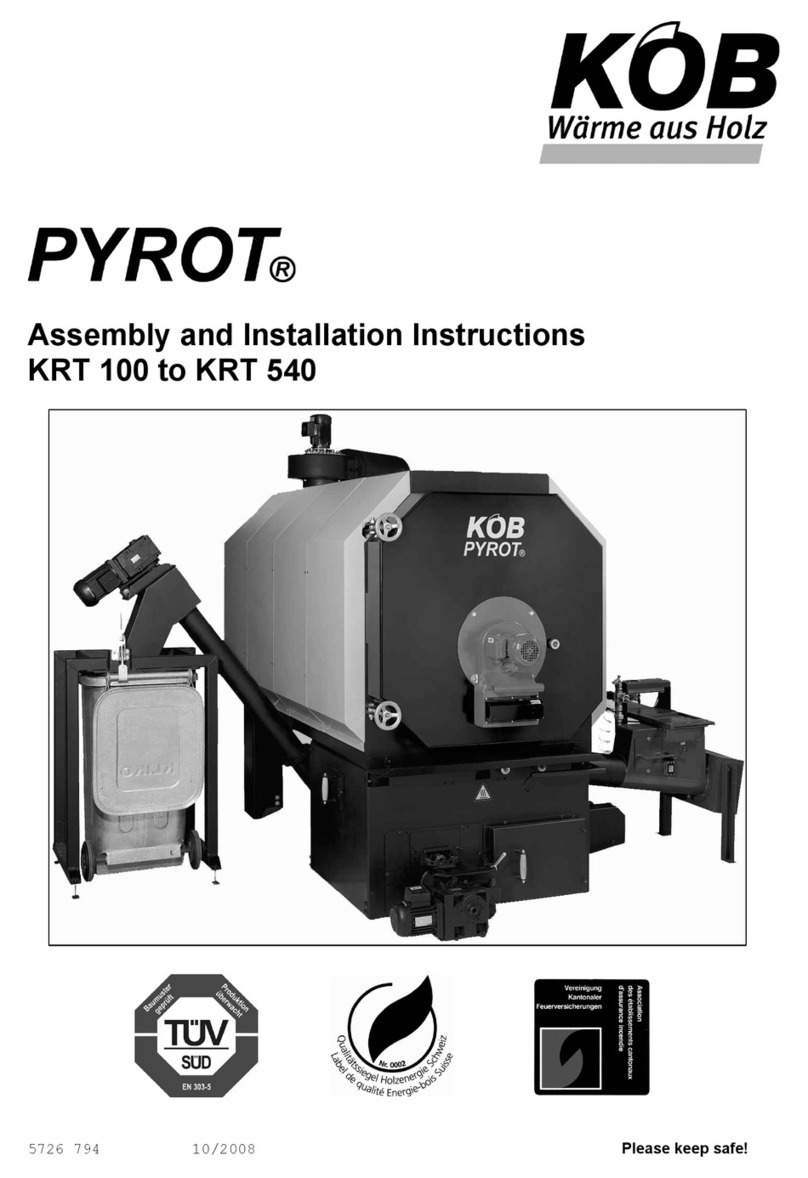

Description

The PYROTEC Grate Firing System (patent no: EP 0 905

442 B1) was developed for automatic combustion of all dry

to moist wood fuels (remnant wood, pellets and forest wood

chips to max. W50, (see section “Wood Fuel Requirements”)

and combines the benefits of underfeed firing with the

benefits of grate firing.

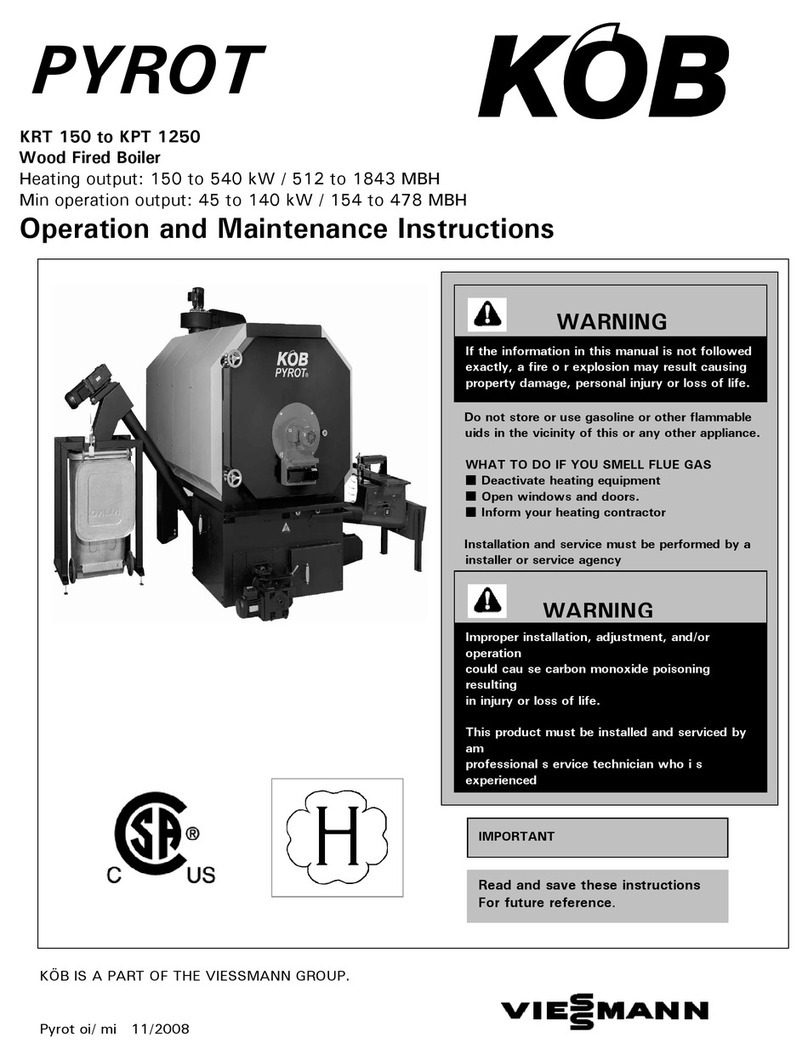

The PYROTEC Grate Firing System is characterized by

highest efficiencies and perfect combustion in all load

stages. The PYROTEC Boiler Plant has been built to

ASME Sec. IV and has CRN for Canada. It is tested and

approved to the applicable CSA / UL safety standards.

Function:

- The solid, powerful and heat-resistant in-feed auger

moves the fuel over the burner trough into the

descending and moving grate zone. An electrical and

mechanical temperature sensor to operate the

thermal extinguishing valve are located on the in-feed

auger. Above the auger is the metering container with

a light barrier for setting the level of the fuel insulating

layer.

- The fuel is either ignited manually or automatically with

an automatic igniter (optional). The boiler features

a reliable burner trough, a descending grate and

a moving burn-out grate made from highly-refractory

cast steel [approx. bin. (12 mm)]. These items allow

to achieve excellent performance control and highest

safety against back-burn in conjunction with an automatic

de-ashing assembly with ash container (optional)

for the combustion chamber.

The solid, horizontally positioned and large-volume

combustion chamber door has been optimized in terms

of combustion, consists of a high-quality refractory

brick lining and has multiple layers of insulation for the

lowest possible surface temperatures. A variable speed

primary air blower provides preheated air to the

combustion grates in the combustion chamber door.

- In the upper part of the combustion chamber door, the

secondary air is blown into the gas space of the firing

system by variable speed blower via an encircling ring

with individually adjustable nozzles to achieve high

turbulence. This mixes the fuel gases with fresh

secondary air to achieve perfect combustion and very

low emissions. The combustion chamber door is

solidly constructed, air-cooled and very well insulated.

The combustion chamber door is equipped with solid

double-jointed hinges for easy maintenance. The heat

is transferred to the water in the horizontal heat

exchanger. The boiler is well insulated and highly

accessible through the heat exchanger door on the

front. A pneumatic cleaning system (optional) can be

installed at the insulated heat exchanger door.

- The flue gas exhaust blower has been specially

designed for wood burning boilers and quiet operation.

The spring-suspended motor has a solid, heat-resistant

design with a heat dissipation hub. The blower housing

on the intake can be mounted radial by 360° and has a

variable rotation speed and a round blow-out nozzle. It

is mounted directly on the boiler or on the flue gas

cyclone (optional).

General Information

Supplied with:

- Boiler with combustion chamber and pressure vessel/

heat exchanger including supply and return

temperature sensors and over pressure monitor

- Combustion chamber with burner trough, descending

grate, moving burn-out grate and light barriers for

ember monitoring

- In-feed auger including insulating layer, safety end

switch for maintenance lid, back-burn temperature

sensor, thermostatic valve for extinguishing assembly,

extinguisher water container with mounting bracket

- Flue gas exhaust blower including flue gas temperature

sensor and oxygen sensor

- Boiler cleaning tools for the combustion chamber

and heat exchanger

- Installation fittings including pressure relief valve, drain

valve, low water cut off, safety temperature limiter,

temperature and pressure gauges

- Control cabinet with integrated Pyrocontrol control

system

Customer supplied:

- Counter flanges for the boiler supply and return

- Piping to the 3-way mixing valve, boiler pump and

thermal storage tank

- Piping for the safety heat exchanger

- Wiring to the control panel

- Insulation for the flue gas re-circulation line, the flue

gas recirculation system is optional

Accessories for PYROTEC Grate Firing System:

- Flue gas cyclone 63 USG (240 L)

- Flue gas cyclone 211 USG (800 L)

- Automatic de-ashing assembly with ash container,

63 USG (240 L)

- Automatic de-ashing assembly with ash container,

211 USG (800 L)

- Pneumatic cleaning system

- Automatic igniter

- Set of displacement rods (for Pyrotec 720, 950 and

1250 only)

- Operating pressure 30 or 60 psi

- Two-stage in-feed auger

- Flue gas recirculation system

- Thermal safety flush valve

- Slide valve / Rotary valve

- Boiler pump and boiler mixing valve

- Pyrocontrol control system options:

- 5 sensor thermal storage tank management system

- External control module for field supplied extraction

system

- Output module / Input module

- Input module 0-10V

- ModBus

- BacNet gateway

- Visualization