4 9

KOBE

INDUSTRIAL

POWER TOOLS

SPECIFICATIONS

MODEL: ...................................... DMM3050

ORDER CODE: .................... KBE-268-4220K

MOTOR: ................ 1200W/240V/50/60Hz

ARBOR: ................................ 19mm Weldon

CHUCK SIZE: ......................................... 1/2”

SPEED: ........................................... 595rpm

MAGNETIC ADHESION: .................. 13,000N

WEIGHT: ................................... 13.5kg NET

SIZE: ........... 390(H) x 260(W) x 100(D)mm

DRILLING CAPACITIES:

Core drill ..................................... 12 - 35mm

Twist drill ................................... 1.5 - 13mm

Countersink ................................ 10 - 40mm

CUTTING DEPTH: .............................. 50mm

STROKE: ......................................... 165mm

SOUND PRESSURE (LPA): .......... 109.5 dBA

SOUND POWER (LWA): .............. 107.8 dBA

VIBRATION LEVEL: ......................... 1.5m/s2

KOBE

INDUSTRIAL

POWER TOOLS

ELECTRICAL INFORMATION

In the United Kingdom, the ELECTRICITY AT WORK ACT 1989 requires all portable electrical appliances, if

used on business premises, to be tested by a qualified electrician, using a Portable Appliance Tester (PAT), at

least once a year. The HEALTH & SAFETY AT WORK ACT 1974 makes owners of electrical appliances

responsible for the safe condition of the appliance and the safety of its operator. If in any doubt about

electrical safety, contact a qualified electrician.

ELECTRICAL SAFETY

An RCCB (Residual Current Circuit Breaker) should be fitted in the mains electricity distribution board. If the

power supply is not protected by an RCCB, it is highly recommended that an RCD (Residual Current Device) is

used with all portable electrical products.

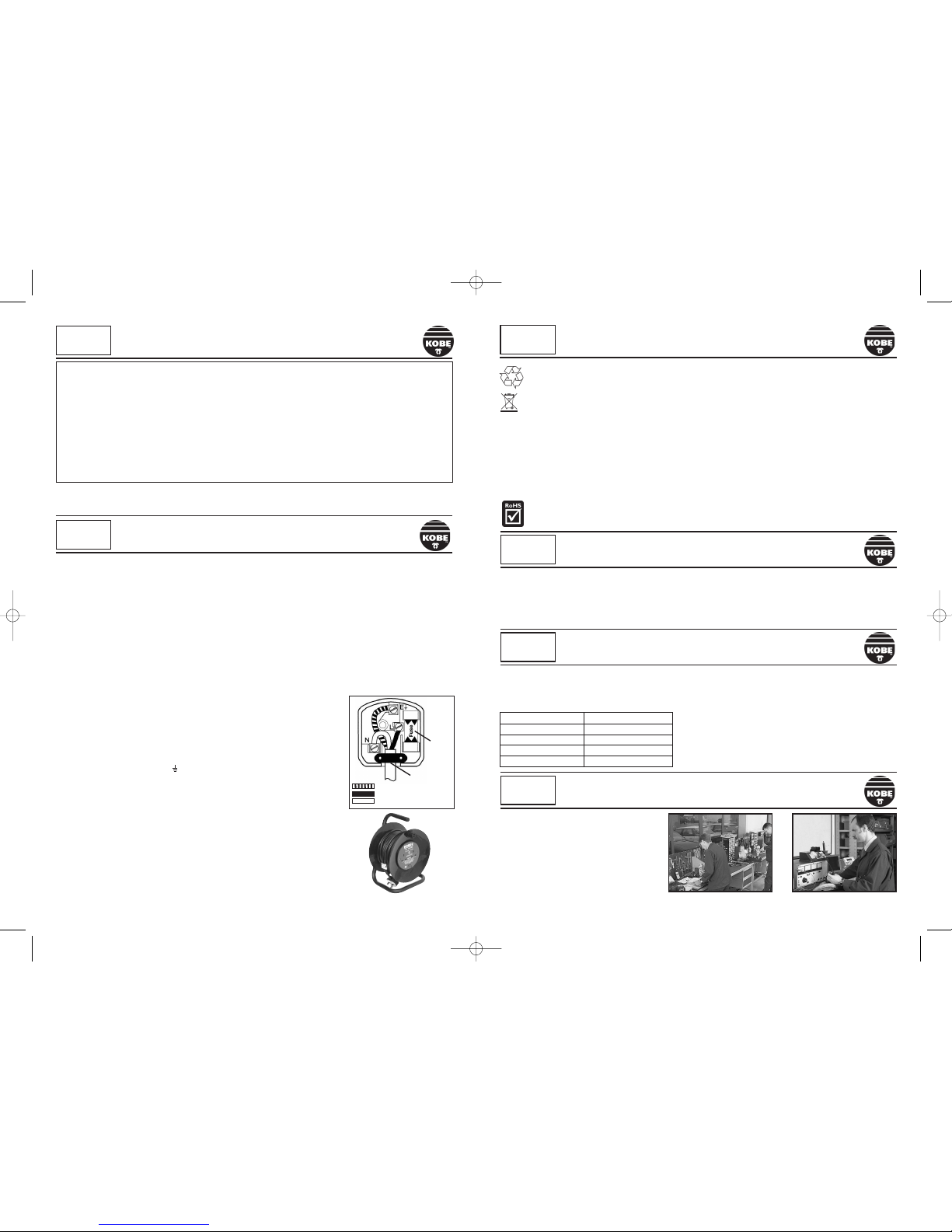

PLUG FITTING

A moulded UK 3 pin plug with ASTA/BS approval is already fitted for your safety.

If it becomes damaged, and needs replacing, cut off the plug and prepare the

wires. Use the following instructions:

a) Connect the GREEN/YELLOW earth wire to the earth terminal marked either

‘ E’ or with the earth symbol‘ ’.

b) Connect the BROWN live wire to the live terminal marked ‘ L’.

c) Connect the BLUE neutral wire to the neutral terminal marked ‘ N’.

d) After wiring, check there are no bare wires, that all wires have been correctly

connected, that the cable external insulation extends beyond the cable

restraint and that the restraint is tight.

EXTENSION REELS

When a cable extension reel is used it should be fully unwound before being

connected. Use at least 1.5mm2 section cable or to be absolutely sure use 2.5mm2

section cable.

Yellow & Green = Earth wire

Cable restraint

UK

ONLY

Brown = Live wire

Blue = Neutral wire

5 amp

fuse

KOBE

INDUSTRIAL

POWER TOOLS

MAINTENANCE

The drill requires very little maintenance apart from keeping all unpainted surfaces coated in light oil.

Keep the machine clear of swarf which should be disposed of in a proper manner and not put into

domestic refuse bins.

Always inspect and check the set up and adjustments before using the machine.

KOBE

INDUSTRIAL

POWER TOOLS

SERVICE & REPAIR

A comprehensive repair and service

facility is available through your

local Kobe agent.

KOBE

INDUSTRIAL

POWER TOOLS

THE ENVIRONMENT

Always dispose of unwanted tools, accessories and packaging materials in an environmentally

friendly manner.

For EU and EEA countries only.

In observance of European Directive 2002/96/EC on Waste Electrical and Electronic Equipment

(WEEE) and its implementation in accordance with national law, electrical goods that have reached

the end of their life must be collected separately and returned to an environmentally compatible

recycling facility.

Do not dispose of electrical goods with domestic waste materials as inappropriate disposal may

cause potential hazards to the environment and human health.

For further information, please contact your local authority or the retailer from whom you purchased

the product.

This product does not contain any restricted substances in concentrations and applications which

are banned by the European RoHS Directive.

KOBE

INDUSTRIAL

POWER TOOLS

SPARES

For spare parts or servicing please contact your nearest agent. Remember to quote tool model number and

spare part number when ordering spares. The use of other than genuine Kobe replacement* parts may

result in safety hazards, decreased tool performance and increased maintenance. When disposing of

components, etc. ensure that relevant environmental procedures are carried out.

Description Order Code

Chuck Guard KBE-298-3783S

Carbon Brushes KBE-298-9944E

Weldon Adaptor KBE-298-3785S

Chuck Key KBE-298-3784S

*(KOBE recommends the use of

KOBE/KENNEDY replacement chucks)

KBE-268-4220K_Instructions.qxd 29/09/2011 12:36 Page 4