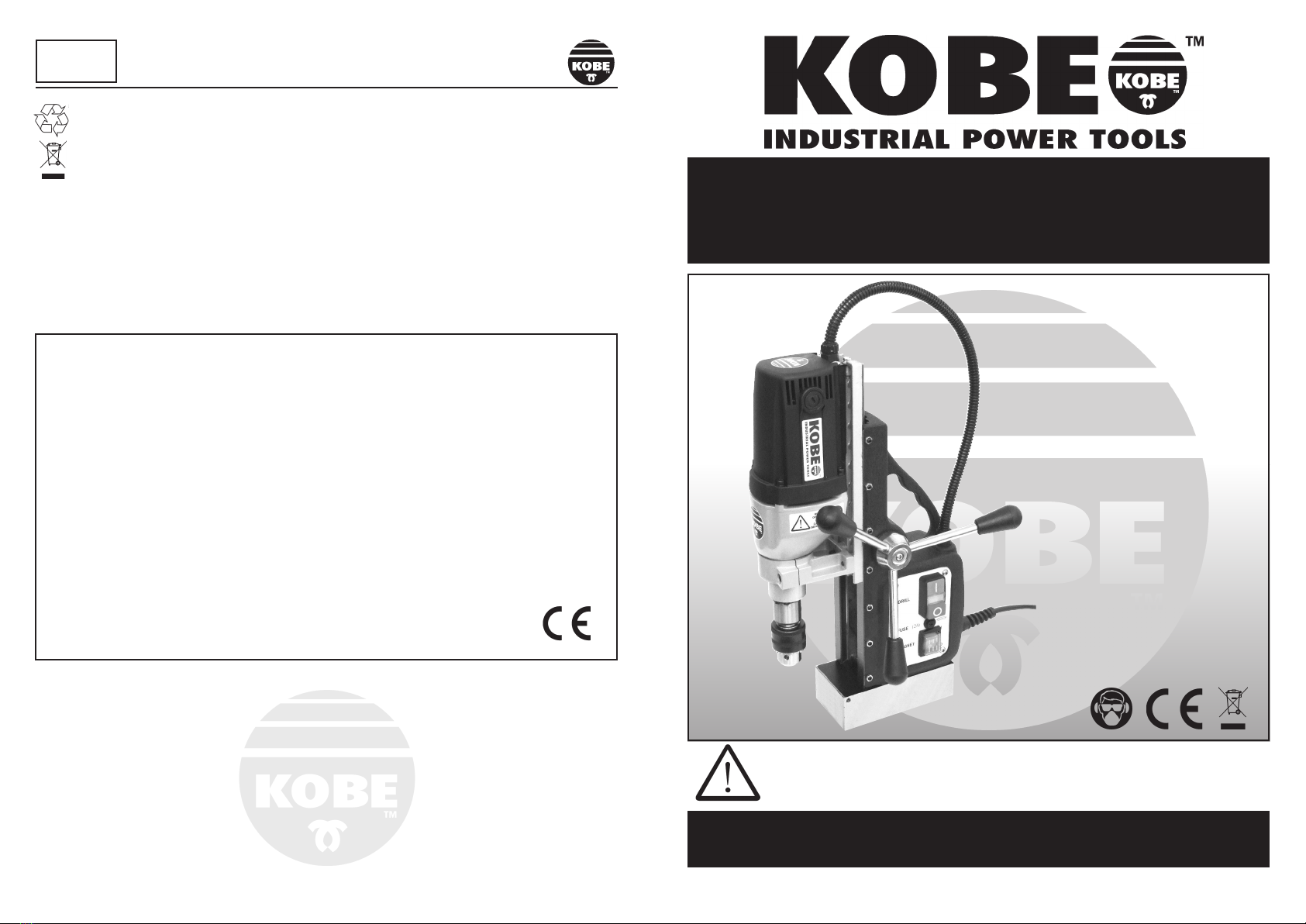

KOBE INDUSTRIAL POWER TOOLS

have been specifically designed to help you work

SAFELY and EFFICIENTLY. Your care and good judgement are the best protection against injury, but

always ensure that the appropriate safety equipment is worn. All possible hazards cannot be covered here,

but the most important ones have been highlighted.

KOBE

INDUS T R I A L

POWER TOOLS

SAFETY INSTRUCTIONS

You have purchased a quality product that is designed for high performance

and long service life. If correct use, safety and maintenance procedures are

observed this machine will last for many years.

lAlways adhere to the processes and safety

warnings, which are stated in the instruction

manual.

GENERAL OPERATING HAZARDS

lAlways ensure the mains power supply

corresponds to the power rating on the

specification label on the machine.

lAlways plug the battery charger into an

appropriate outlet that is properly installed and

grounded in accordance with all local codes and

ordinances. Check with a qualified electrician if

you are in doubt as to whether the outlet is

properly grounded.

lAlways ensure the maintenance of electrical

components is carried out by a suitably qualified

person.

lNever allow routine to lead to mistakes.

lNever operate if any parts are missing or

damaged.

lNever allow untrained persons to operate the

tool.

WORKPLACE HAZARDS

lAlways ensure your working area is clean and

well lit.

lWhen working at height make sure that the tool is

safely secured and be aware of objects falling

below. Make sure that no persons are working

directly below the working area.

lDo not operate in explosive atmosphere, for

instance extreme dust, gases and liquids.

lKeep children and bystanders away while

operating the tool. Distractions can cause you to

lose control.

lAlways ensure all users are physically able and

competent to handle the size and weight of

items/components being drilled and have

received appropriate training to perform the task.

l Never run the tool in areas exposed to water or

in damp conditions.

PERSONAL PROTECTION

.

lAlways ensure that all long hair and loose clothing,

ties, scarves, jewellery, etc., are secured or

removed.

lAlways consult a doctor if numbness, tingling,

pain or whitening of the skin occurs. Repetitive

work motions, awkward positions and exposure

to vibration can cause “Repetitive Strain

Injuries”.

lWhen operating the tool stay alert and use

common sense, especially when it comes to

working at height. Be aware of what’s below you.

lDo not overreach. Keep a proper balance and

footing at all times.

lRemove any adjusting key or wrench before

turning the power tool on.

lDo not use the tool if under the influence of

alcohol, drugs or medication.

SPECIFIC SAFETY INSTRUCTIONS

lThe pillar drill must only be used on metal plate

with a minimum thickness of 6mm.

lAlways ensure the electric cable is not damaged

before connecting the Mag Drill to the electricity

supply.

lAlways use recommended attachments or parts

and make sure that they are kept sharp and fitted

correctly, that all the securing bolts are tight and

the guard is fitted and operating correctly and

that the chuck key and any other adjustment

tools have been removed.

lWhen drilling use the correct cutting

lubricant/coolant for the material being drilled.

Use only sufficient to prevent the drill from

overheating and make sure that it is kept well

away from electrical components.

Never use water as a coolant.

lWhen drilling long lengths ensure that there is

adequate support at both ends of the material.

lNever use the machine without the safety guard

in position and operating correctly.

lAlways secure the workpiece with suitable

clamps.

lAlways switch off using the on/off switch when

not in use.

lNever use the Drill without the guard attached.

lNever deface the rating plate on the drill.

lNever make any alterations to the Drill and only

use it for the task for which it has been designed.

211

NOTES