©

B

R

E

A

T

H

E

S

A

F

E

2

0

1

9

www.breathe-safe.com.au

Page 9

Issue date:

Controlled document:Revision:

WA900-3EO

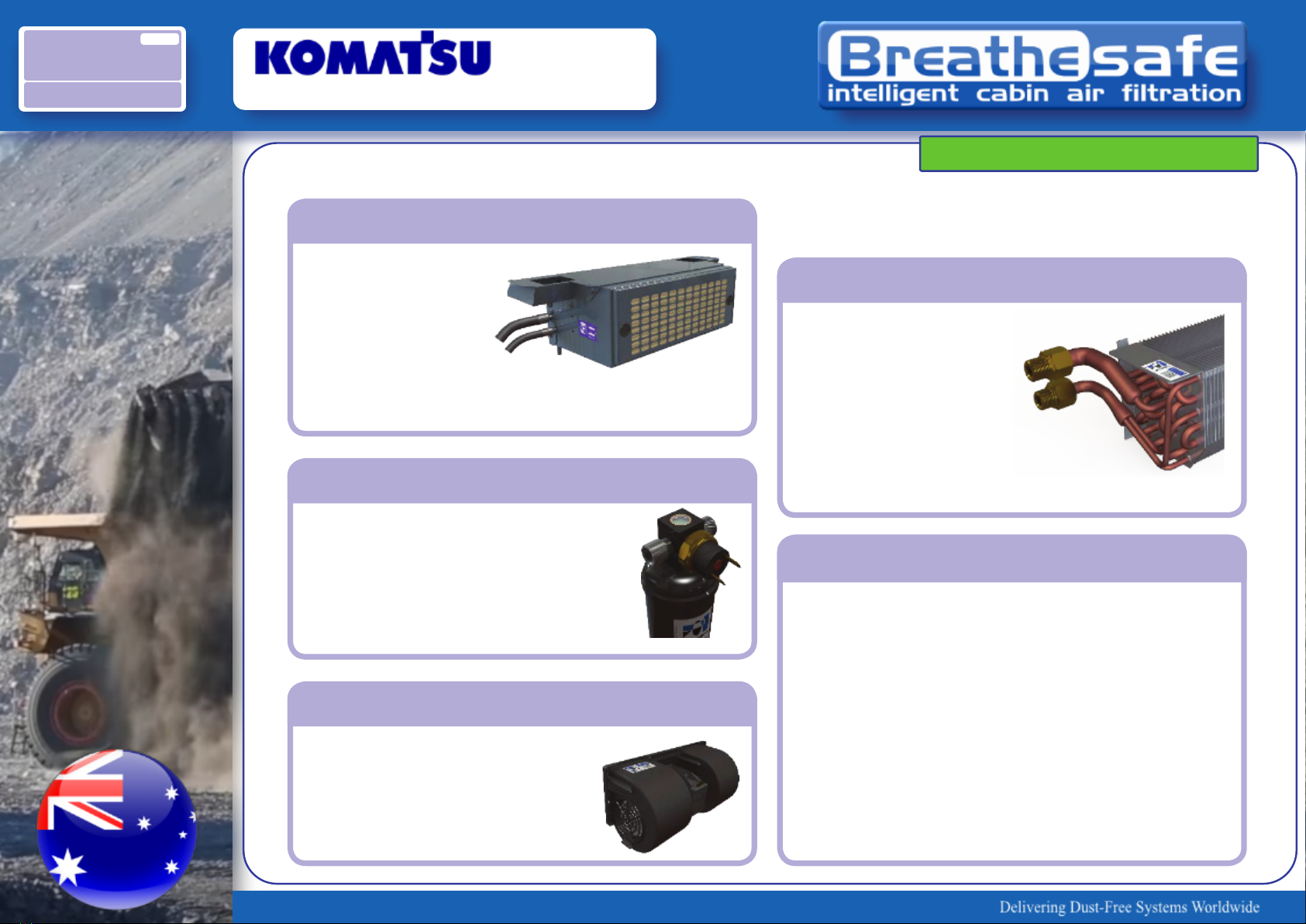

4. Evaporator Coil

The evaporator coil is constructed from

copper tubing, through which passes

the R134a refrigerant, and aluminium

ns for optimum heat transfer. The

refrigerant evaporates as it passes

through the copper tubes due to heat,

which it absorbs from the hot air owing

over and around the ns and tubes.

This absorption of heat reduces the

temperature of the air passing through

the coil, thus cooling the cab. The

refrigerant boils o becoming a low

pressure gas.

5. Compressor

The function of the compressor is to

compress the refrigerant in the system,

thus concentrating the resultant rise in

temperature. At the compressor, the

low pressure gas is changed to a high

pressure, high temperature gas. This

pressure build-up is accomplished by

having a restriction in the high pressure

side of the system. This restriction

occurs at the metered orice in the T.X.

valve.

The compressor is normally belt

driven from the engine PTO. An

electromagnetic clutch is typically

used to provide a means of stopping

the compressor from pumping when

refrigerant ow is not desired or when a

malfunction develops within the system.

6. Compressor Service Valves

Two service valves are located on the

top of the compressor cylinder head.

The valves enable the connecting

of system test gauges and also to

isolate the compressor from the rest of

the system to facilitate compressor

replacement. The high (discharge) side

service valve is quickly identied by the

smaller discharge hose routed to the

condenser, while the low (suction) side

has a larger hose coming from the

evaporator.

The valve is normally back-seated,

closing o the gauge port allowing

normal system operation. The valve

should be in this position before

disconnecting any service equipment.

The valve should be in the mid position

when the system is operating and any

service equipment is connected. Loss

of refrigerant gas will occur if the valve

is opened to this position without rst

connecting the service equipment.

The front-seated position of the valve

shuts o ow to both the gauge port

and compressor. This position is used

when isolation of the compressor

from the rest of the system is desired.

Operation of the compressor with the

valve in this position will result in severe

compressor damage due to excessive

build-up.

HEATING CIRCUIT

The heater coil (if available), is supplied with

hot water from the main engine cooling

system.

Control is via a manually operated valve in

the supply line or via the electronic

thermostat (if available), which can be

operated whilst in cooling mode to provide

some humidity control and rapid demisting.

ELECTRICAL CIRCUIT

Battery power is circuited through a circuit

breaker to the main four-position switch or

electronic thermostat (if available) which

provides for control of the three-speed

recirculating (supply) air fan.

The compressor clutch is in series with the

High Pressure / Low Pressure safety switch

and thermostat protecting the system.

A circuit breaker operates through a relay to

supply full voltage to the condenser fan

motors.

PRINCIPALS OF AIR CONDITIONING

OVERVIEW