KOMAX products are designed, developed and manufactured

with state-of-the-art technologies in modern facilities. The pumps

are produced with great care and commitment to continuous

quality control, utilizing sophisticated quality techniques, and

safety requirements.

KOMAX is committed to continuous quality improvement and

being at service for any further information about the product

in its installation and operation or about its support products,

repair and diagnostic services.

These instructions are intended to facilitate familiarization with

the product and its permitted use. Operating the product in

compliance with these instructions is important to help ensure

reliability in service and avoid risks. The instructions may not

take into account local regulations; ensure such regulations are

observed by all, including those installing the product. Always

coordinate repair activity with skilled personnel, and follow all

plant safety requirements and applicable safety and health laws

and regulations.

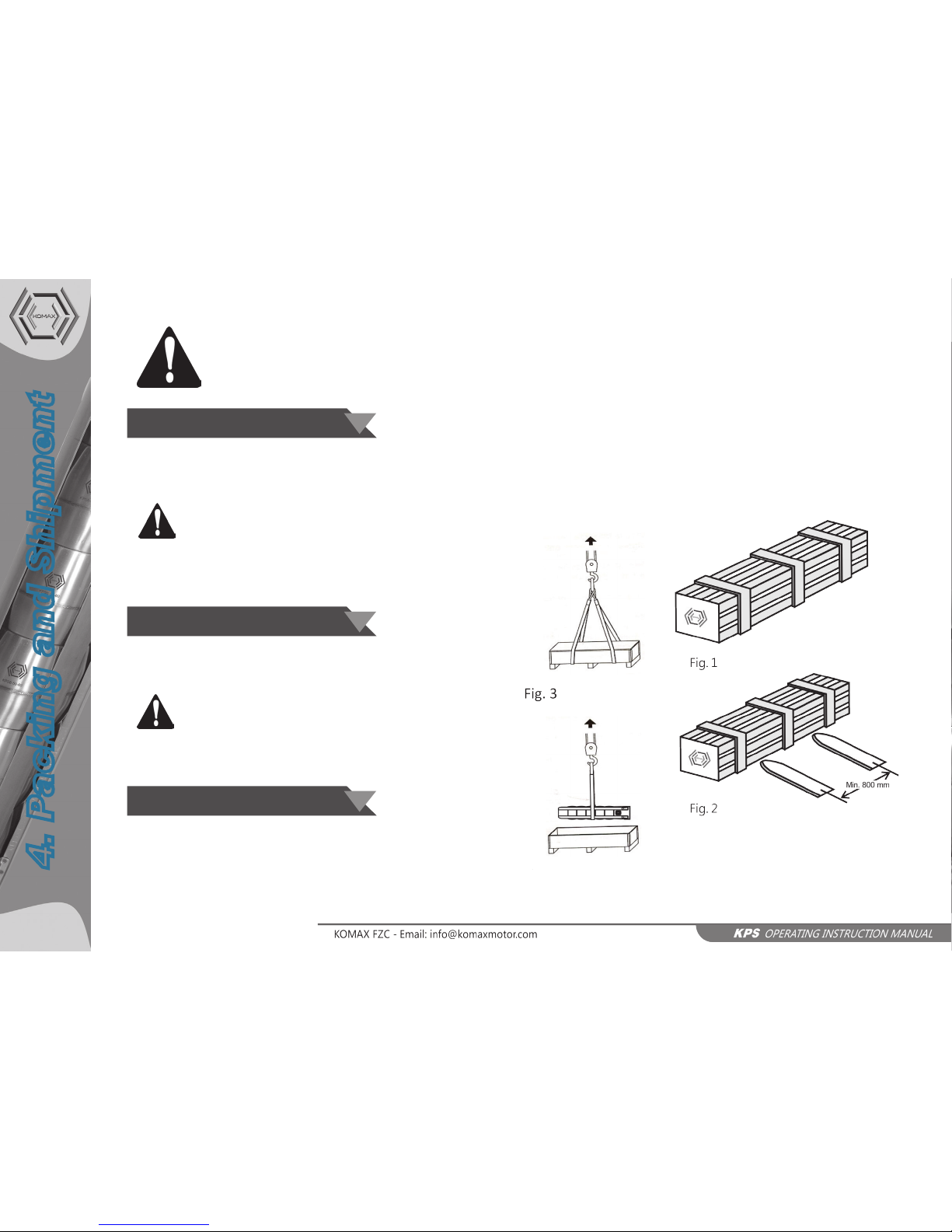

The pumps are carefully inspected and tested before

displacement. Check however the equipment at delivery against

the accompanying documents. Check box integrity before

removing the pump. Parts and accessories can be packed alone

or fastened to the box. If something is missing or damaged,

please contact immediately your local forwarding agent or local

distributor.

We strongly recommend to read it attentively and to consult

it whenever work is done on the pump. Un-observance of the

instructions here reported or improper use of the pump by

unskilled personnel may compromise pump life and proper

operation and may cause injury.

Assembly, installation, working, Extraordinary maintenance,

repair, overhaul, handling and dismantling of the pump must be

carried out by skilled technicians authorized by the Authorized

Manufacturer or Distributor/Dealer. The manufacturer does not

hold any responsibility for any damage to persons or things due

to wrong interventions carried out by unauthorized personnel or

by an improper and incorrect use of the pump.

In order to better understand the language of the present

manual, the pump user must be in possession of the necessary

qualifications in servicing and maintenance; he must have the

necessary knowledge to make out drawings and descriptions of

the manual, he must be educated and trained about the general

and specific accident prevention measures in force in the country

where the pump is installed.

The same criteria is valid for choosing the technical maintenance

personnel who, additionally, must have the necessary knowledge

of specific and specialized regulations (mechanical and electrical)

to safely carry out those interventions described in the manual.

KOMAX manufactures products in complaince to International

Quality Management System Standards as certified and audited

by external Quality Assurance organization. Genuine parts and

accessories have been designed, tested and incorporated into

the products to help ensure their continued product quality and

performance in use. As KOMAX cannot test parts and accessories

sourced from other vendors the incorrect incorporation of such

parts and accessories may adversely affect the performance

and safety features of the products. The failure to properly

select, install or use authorised KOMAX parts and accessories is

considered to be misuse. Damage or failure caused by misuse is

not covered by the KOMAX warranty. In addition, any modification

of KOMAX products or removal of original components may

impair the safety of these products in their use.

1. Introduction

1. Introducon

03