EN

page 27

2.2.2 Operation

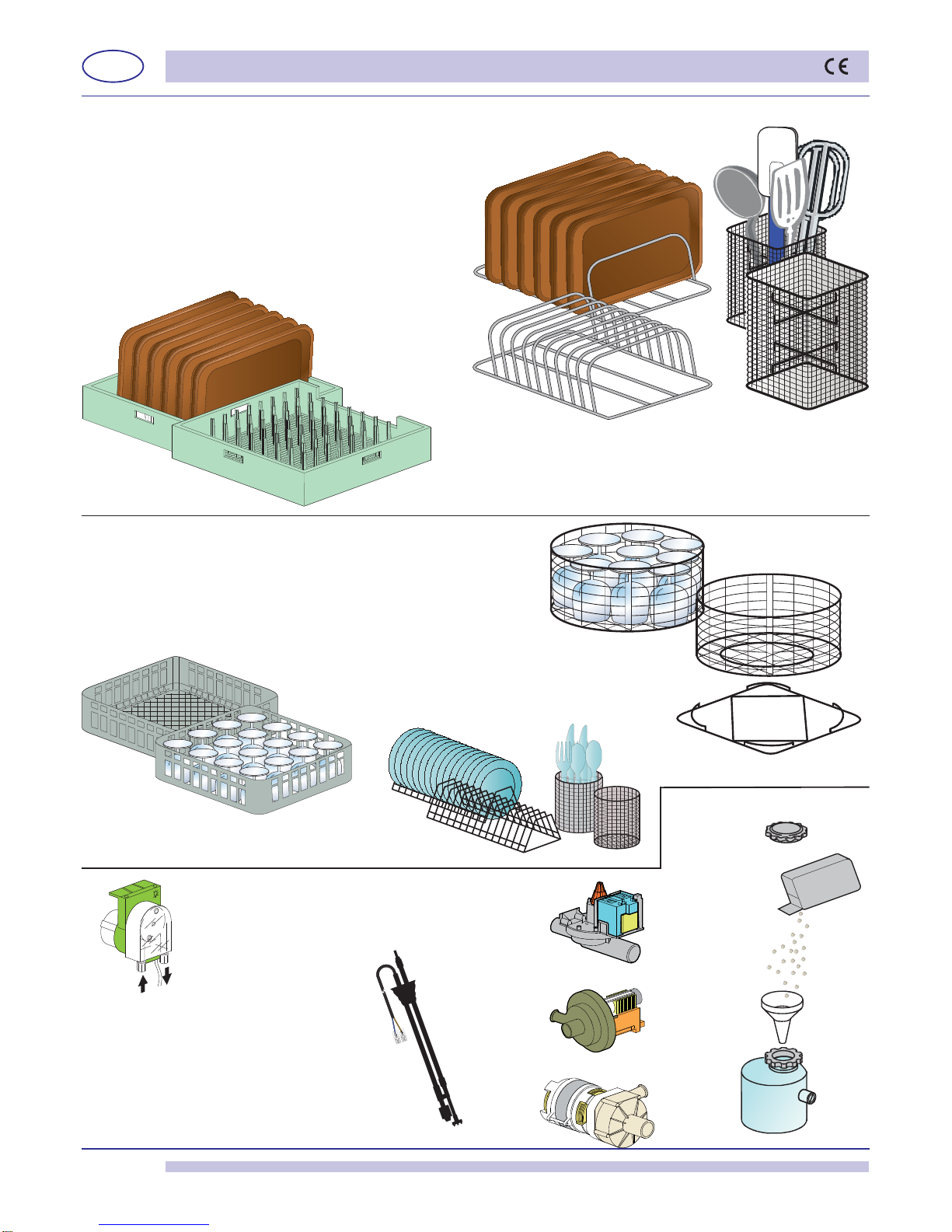

• Insert the rack filled with dishes to wash. The plates must be correctly placed in the rack

(see pict. 3).

Close the door.

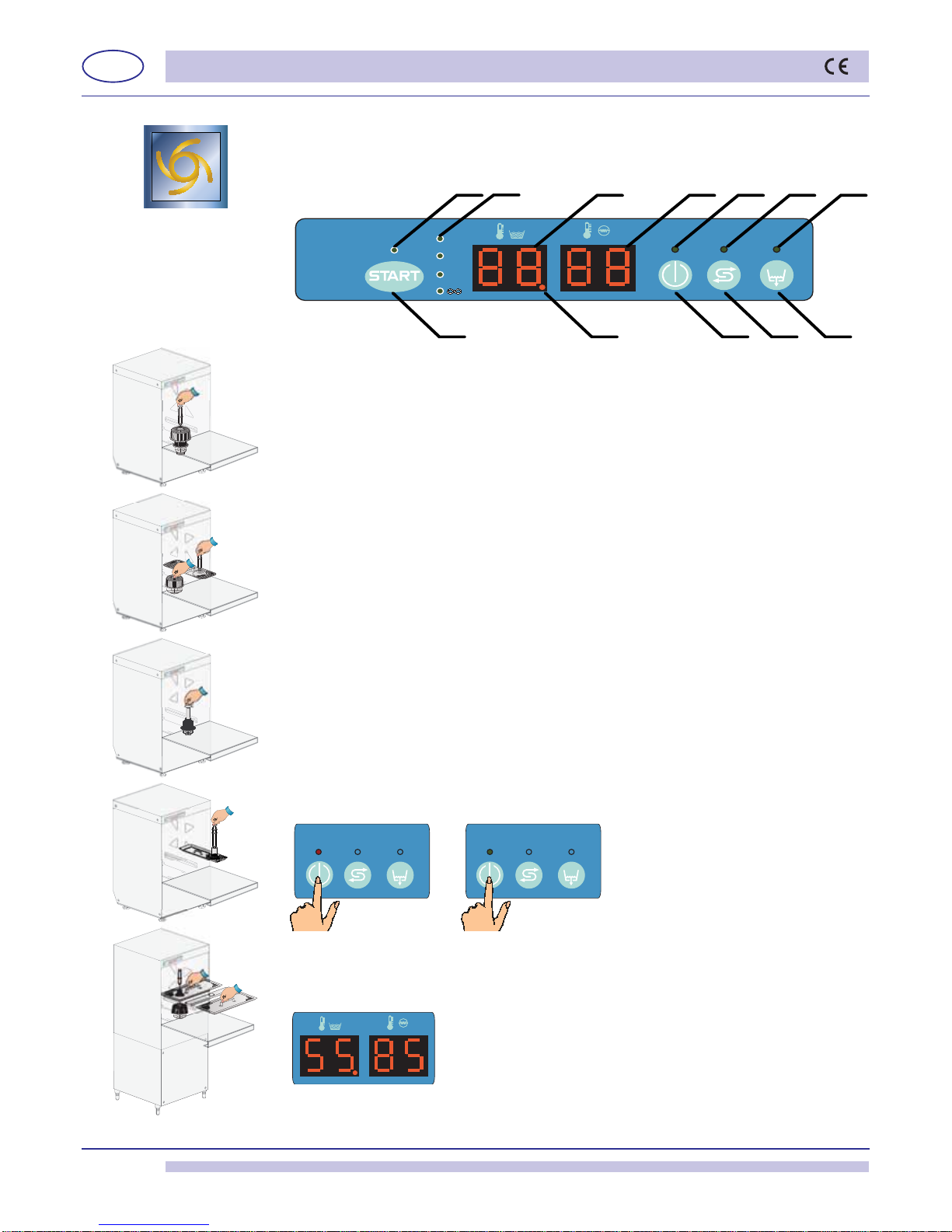

• Select the wanted washing cycle (1, 2, 3, ∞) by pushing the button "H" (see pict. 1). The

display will show in sequence all available programs.

Once the wanted program is displayed, do release the button.

The green LED "B" of the selected cycle lights up (1, 2, 3, ∞).

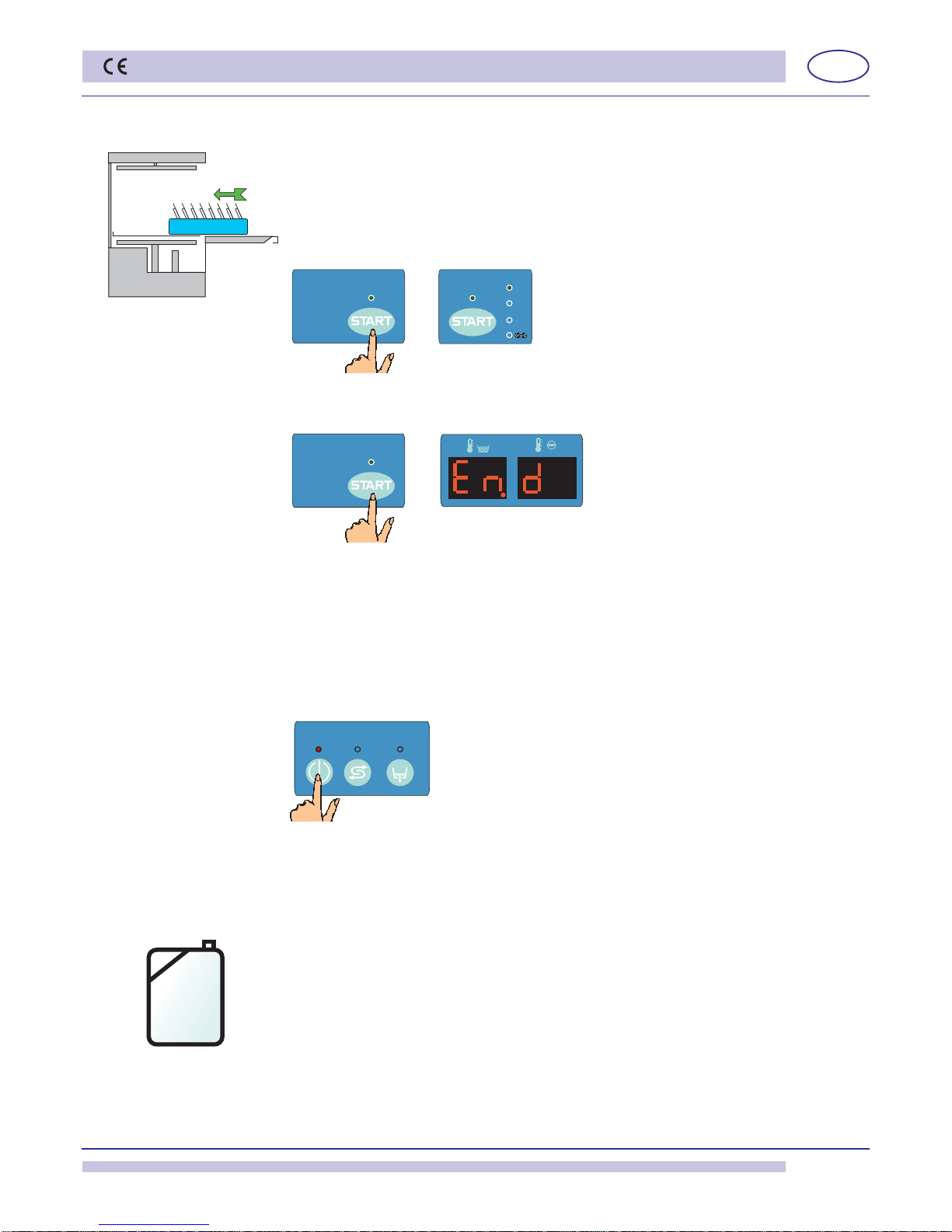

• Start the cycle by pushing the button "H" for not more than 1sec (see pict. 1). Starting

of the cycle is signalled by the indicator of the selected cycle flashing. At the end of the

cycle the indicator stops flashing and the message "END" appears on the display.

• The machine is ready for a new wash.

It is advisable to change the tank water, by means of another filling, at least every 40-50

washes or twice a day.

N.B.: the machine does not accept other cycles until the door is opened or the button "H"

is pressed twice (see pict. 1).

The cycles (1, 2, 3, ∞) are factory-set with times of 60 - 120 - 180 - 300 seconds.

2.2.3 Switching OFF

• Turn the button "J". The machine will turn in "STAND-BY" mode (the red LED "E" comes

ON).

• Drain completely the wash-tank. Take off the overflow pipe. For machines equipped with

drain pump see par. 2.5.

• Switch the main power switch OFF.

• Shut the water valve.

• At the end of the day, clean the machine (see chap. 5 Maintenance).

2.3 Detergent use

The detergent shall be the NO FOAM type, suitable for industrial dishwashers.

The use of good quality liquid detergents is recommended.

The detergent must be introduced in the tank. The amount is recommended by the manu-

facturers according to the water hardness.

By request the dishwasher can be equipped with an electric detergent dispenser (always

recommended).

1cm. of the product drawn into the tube is equal to about 0.15 g. A correct amount of deter-

gent is very important for a successful wash.

Should the detergent lack, the display will show "NO DE" (only with optional "Sensor for

Chemicals Low Level").

pict. 3

2

3

1

DETERGENT