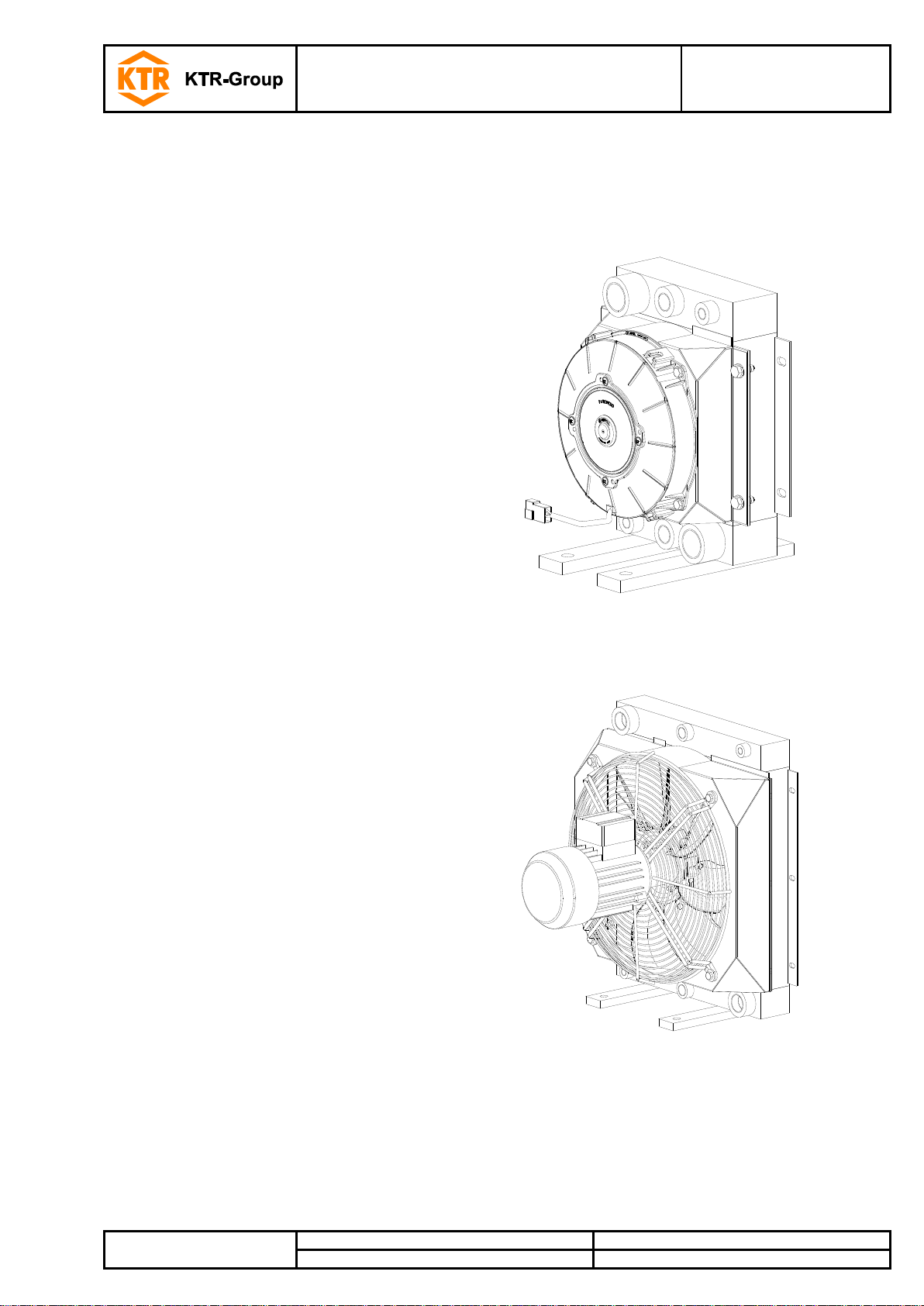

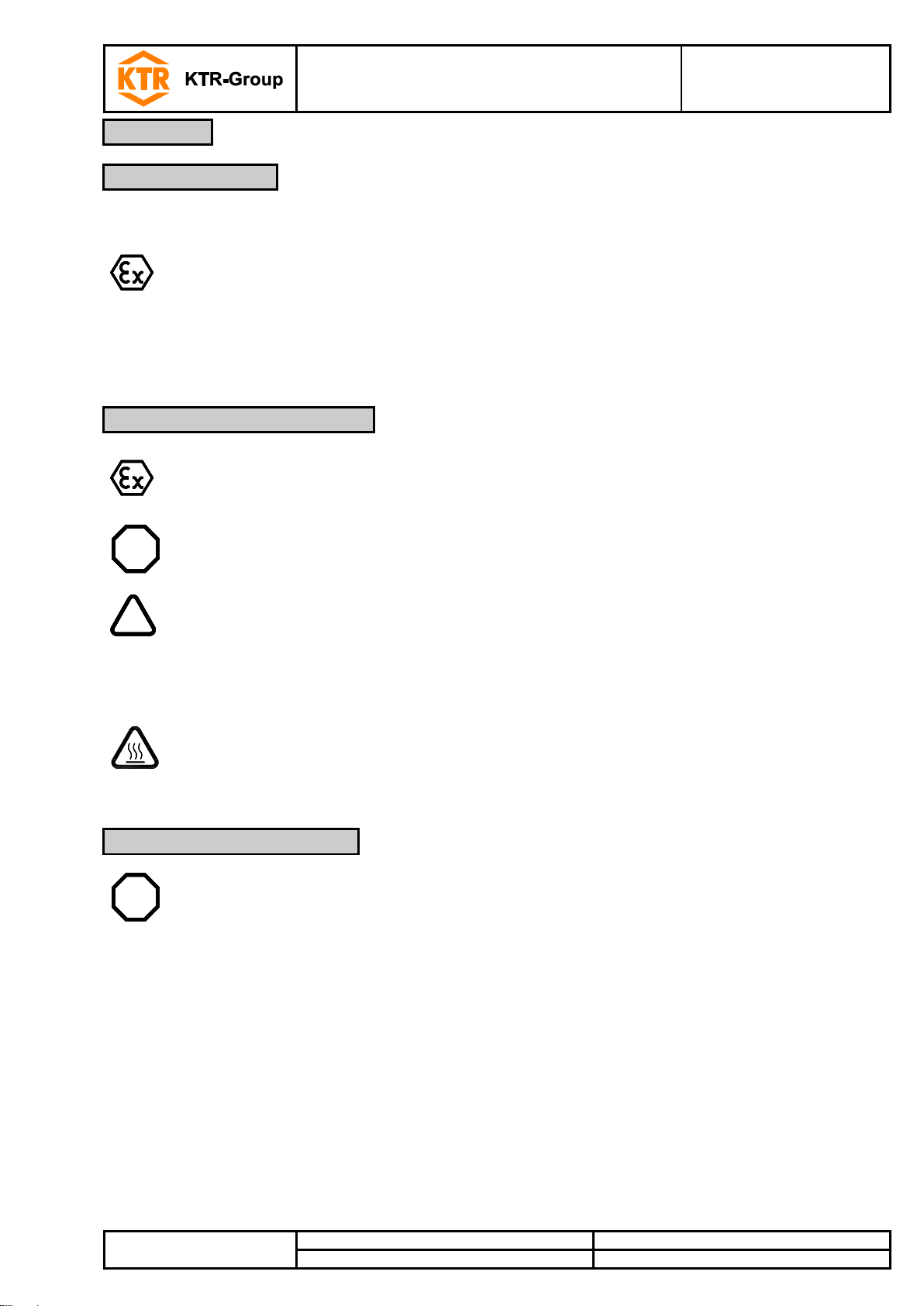

The oil/air cooler series OAC is an efficient high-performance cooler. It has a compact design and was

developed for cooling hydraulic oil, gear oil, lubricant and water-glycol.

1Technical data 3

2Advice 7

2.1 General advice 7

2.2 Safety and advice symbols 7

2.3 General hazard warnings 7

2.4 Intended use 8

3Storage, transport and packaging 8

3.1 Storage 8

3.2 Transport and packaging 8

4Assembly 9

4.1 Components of oil/air cooler 9

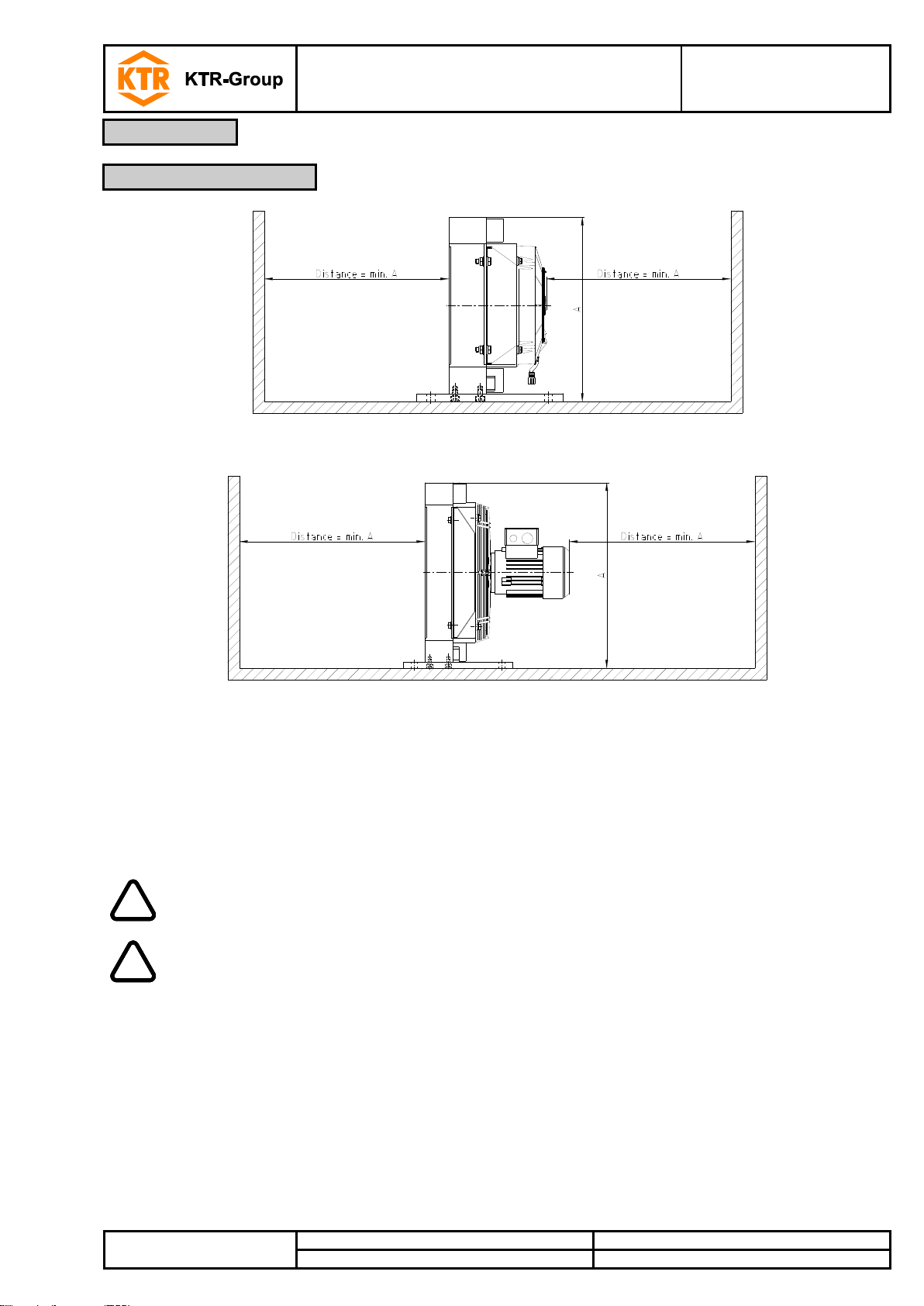

4.2 Place of installation 10

4.3 Assembly of oil/air cooler 11

4.4 Thermal switch 11

4.5 Operating pressure and temperature 11

4.6 Electrical connection 12

4.7 Cooling medium 12

4.8 Cleaning 13

4.9 Marking of standard oil/air cooler 13

4.10 Diagrammes - pressure loss and power 13

4.11 Assembly - disassembly of the oil/air cooler into components 15

5Start-up 16

6Maintenance and service 16

7Spares inventory, customer service addresses 17

8Enclosure A

Advice and instructions regarding the use in potentially explosive atmospheres 18

8.1 Intended use in potentially explosive atmospheres 18

8.2 Marking for potentially explosive atmospheres 19

8.3 Start-up for the use in potentially explosive atmospheres 20

8.4 Permissible accessories for the use in potentially explosive atmospheres 21

8.5 EC Certificate of incorporation 22

8.6 EU Certificate of conformity 23