Contents

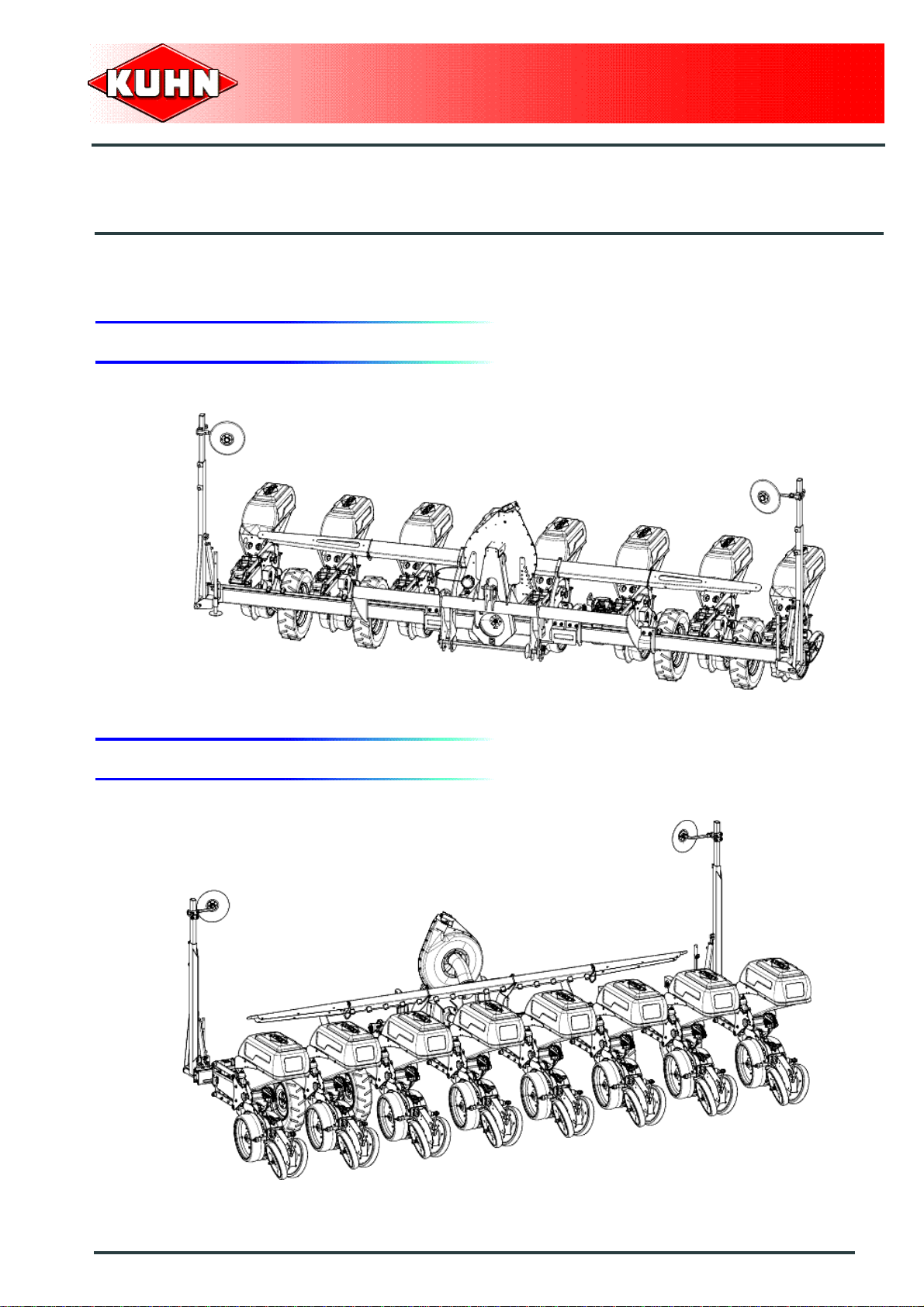

Precision Seed Drills

MAXIMA 2

3

Instructions for work....................................................................................................74

Putting the machine into work position ...................................................................................... 74

Adjustments in working position.................................................................................................75

Machine use................................................................................................................................. 105

Optional equipment....................................................................................................114

Clod clearer...................................................................................................................................118

Spring assisted clod clearer........................................................................................................119

Star shaped trash remover ......................................................................................................... 121

Furrow opening disk ................................................................................................................... 123

Covering scraper......................................................................................................................... 125

Composite intermediate axial press wheel............................................................................... 126

Stainless steel intermediate axial press wheel......................................................................... 128

Furrow closing disks................................................................................................................... 131

Standard V-shaped roller ............................................................................................................ 132

HD V roller.................................................................................................................................... 136

"OTIFLEX" 370 x 165 roller......................................................................................................... 141

"OTIFLEX" 500 x 175 roller......................................................................................................... 143

Left and right rear drive wheels 5 x 15 ...................................................................................... 145

Left and right rear drive wheels 6.5 x 15 ................................................................................... 145

Left and right rear drive wheels 26 x 12 .................................................................................... 145

Microgranulator ........................................................................................................................... 146

Fertilizer unit................................................................................................................................ 164

Low flow kit for the fertilizer unit ............................................................................................... 180

Filling auger ................................................................................................................................. 181

Distribution disks ........................................................................................................................ 183

Rear PTO output stub.................................................................................................................. 184

Vacuometer .................................................................................................................................. 185

HECTOR 3000 electronic control box........................................................................................ 185