If this stove is not properly installed, a house fire can occur. For your protection, follow the installation

instructions provided. We recommend contacting local building or fire officials regarding restrictions and

installation inspection requirements in your area. We also recommend that your Kuma stove be installed by a

properly trained and licensed installer, preferably an NFI (National Fireplace Institute) expert.

DO NOT CONNECT THIS UNIT TO A CHIMNEY FLUE SERVICING ANOTHER APPLIANCE.

Do not burn garbage or flammable fluids such as gasoline, naptha or engine oil. Do not use charcoal lighter

fluid or similar liquids to start or “freshen up” a fire in this stove. Keep all such fluids well away from the stove

while in use. Storing these fluids near a stove could cause a fire.

DO NOT CONNECT TO ANY AIR DISTRIBUTION OR DUCT SYSTEM.

DO NOT OVERFIRE. If any part of the stove or chimney glows, the stove is in an over fire condition. If this

happens, shut the air control off immediately. Over firing can cause damage.

WARNING: DO NOT INSTALL IN A SLEEPING ROOM OF A MOBILE HOME.

An improperly drafting stove can cause smoke and carbon monoxide to enter the home. Smoke detectors and

carbon monoxide monitors are recommended to be installed in the same room as this stove.

CAUTION: THE STRUCTURAL INTEGRITY OF THE FLOOR, WALLS, ROOF/CEILING, AND VAPOR BARRIERS

MUST BE MAINTAINED.

DO NOT USE SINGLE WALL PIPE OR CONNECTOR PIPE FOR ANY CHIMNEY APPLICATION, EXTERIOR OR

THROUGH THE WALL OR CEILING. Single wall pipe may only be used as a connection between the stove and an

approved masonry or stainless steel chimney. Single wall pipe may not be used as a connector in mobile

homes.

When installing into an existing masonry or metal chimney, examine the chimney system carefully. If you have

any questions, seek professional advice. We recommend having existing chimneys cleaned and inspected by a

qualified professional prior to the installation of your new stove.

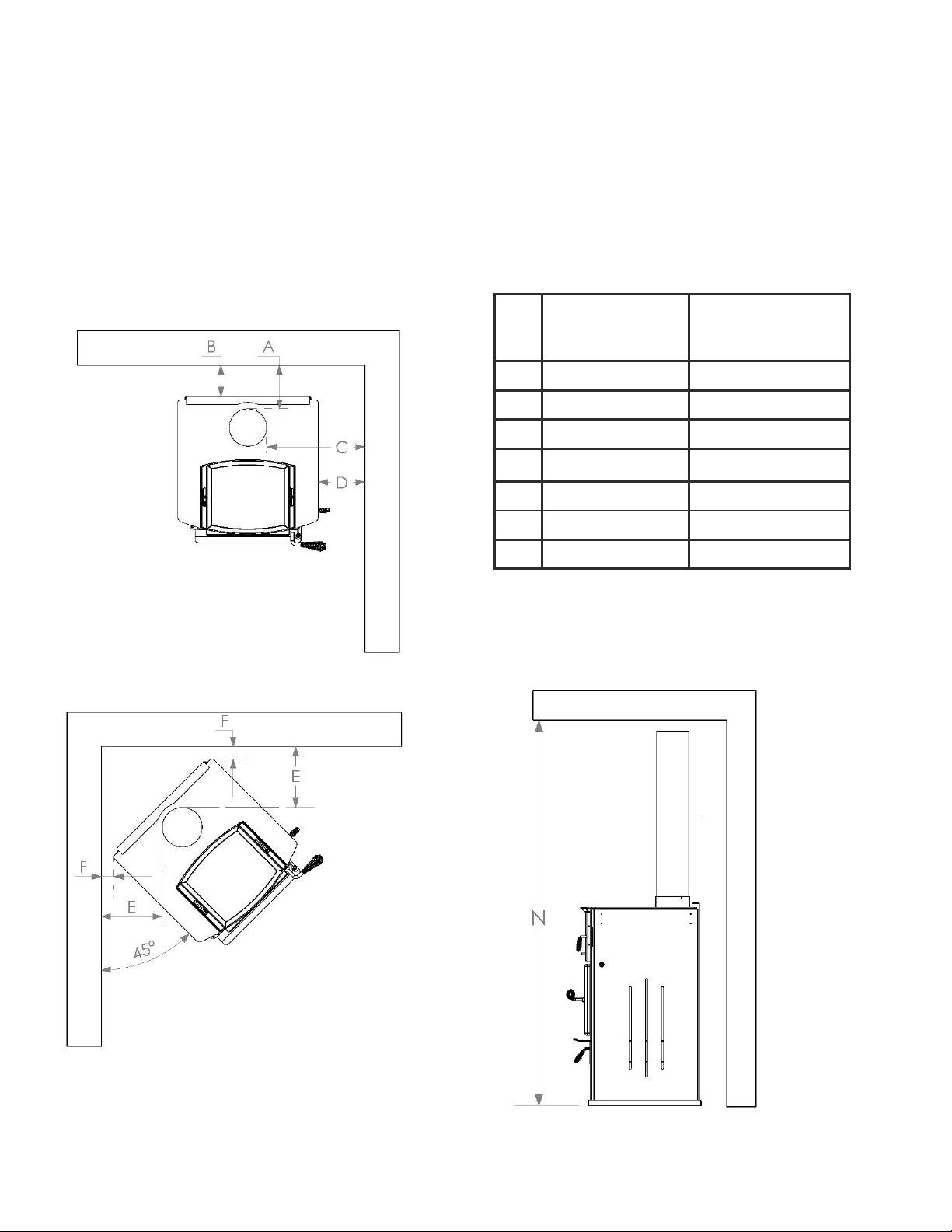

NOTE ALL MINIMUM CLEARANCE REQUIREMENTS TO COMBUSTIBLES. Installation must comply with

minimum clearances as listed in this manual. Clearances may only be reduced by means approved by the

regulatory authority.

Do not operate this stove with the door in an open position, except for cracking open during start-up. Continued

operation with the door open can cause overheating of the unit, and expose embers to nearby combustibles.

Do not operate with broken glass. Do not abuse glass such as striking or slamming the door.

This stove must be connected to a minimum 6” diameter listed chimney that complies with U.L. type 103HT

factory built chimney or a code approved masonry chimney. When installing into masonry chimneys, a U.L. 1777

approved liner must be installed. TO BE IN-STALLED AS A FREESTANDING COOK STOVE WITH THE

CLEARANCES IN THE MANUFACTURER'S INSTALLATION INSTRUCTIONS. NOT TO BE INSTALLED IN ANY

FACTORY-BUILT FIREPLACE.

When connecting single wall or double wall connector pipe to the stove and chimney, use 3 screws per pipe joint

including 3 screws securing the pipe to the stove. Depending on the type of double wall pipe you are using, it may

also be necessary to fasten it at the chimney.

Use only approved components for Chimney and Connector. Field fabricated or “makeshift” components are not

allowed and can cause a fire.

When connecting this stove to a masonry chimney, make sure you observe all applicable clearances including

walls, ceilings and other combustible material. A masonry chimney must be minimum 6” diameter and

constructed with a liner according to NFPA code 211. If you have any questions about the condition or the code

compliance of your masonry chimney, please speak with a qualified professional.

HOT WHILE IN OPERATION. KEEP CHILDREN, CLOTHING AND FURNITURE AWAY. CONTACT MAY CAUSE

SKIN BURNS.

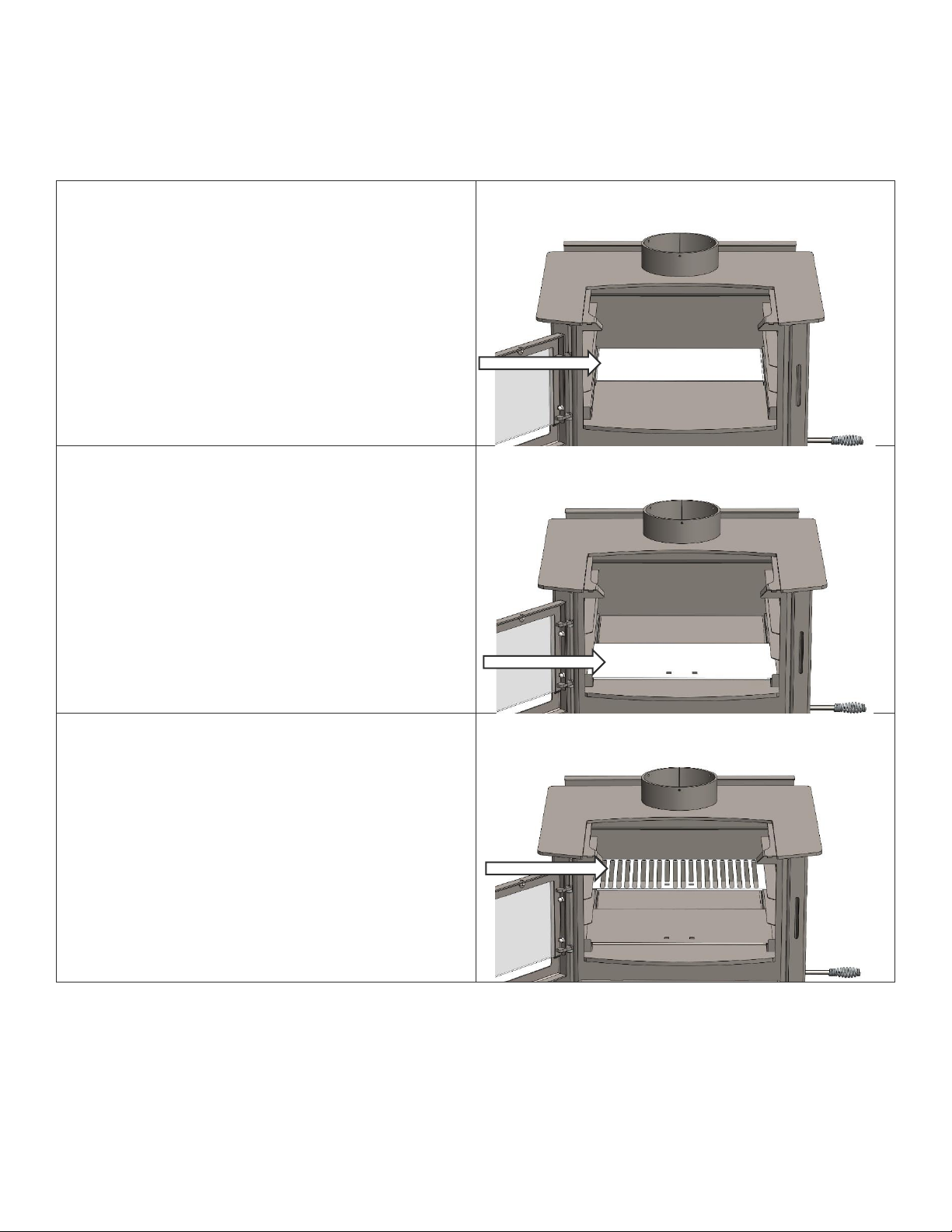

DO NOT PUT WOOD OR ANY COMBUSTIMBLE MATERIAL IN THE STORAGE AREA UNDER THE

STOVE.