TABLE OF CONTENTS 2

Contents ……………………………………………...…1

Forward …………………………………………...…… 2

Feature…………………………….......................………2

Specication ………………………….................………2

Safety precautions …………………………………...… 3

Maintenance record ……… ……………………....……4

Maintenance schedule…………................................……5

Operation elements………................................…………7

Operation (oating)…………………..........................…8

Operation (nishing)…………………………............…8

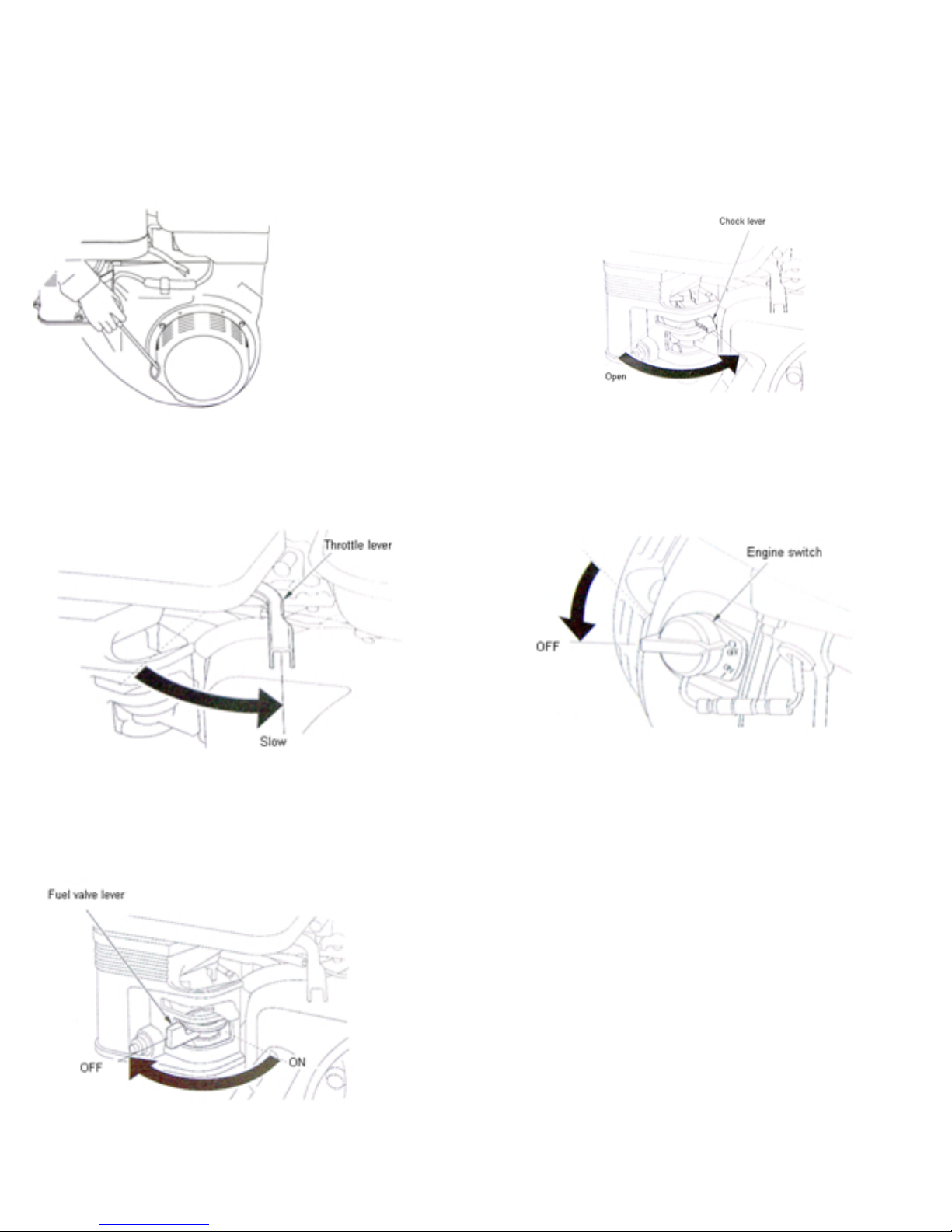

Starting & stopping procedure…………………………9

1. Before operation checks…………………………...…9

2. Starting engine procedure……………………………9

3. Stopping engine procedure……………………….…11

4. Setting engine speed………………………...………12

Lubrication………………………………………….…12

1. Engine oil lever check………………………………12

2. Engine oil change……………………………………13

Spark plugs…………………………………………….13

Carburetor adjustment……………………………..…14

Air lter service………………………………………..15

Storage…………………………………………………16

Troubleshooting…………………………………….…16

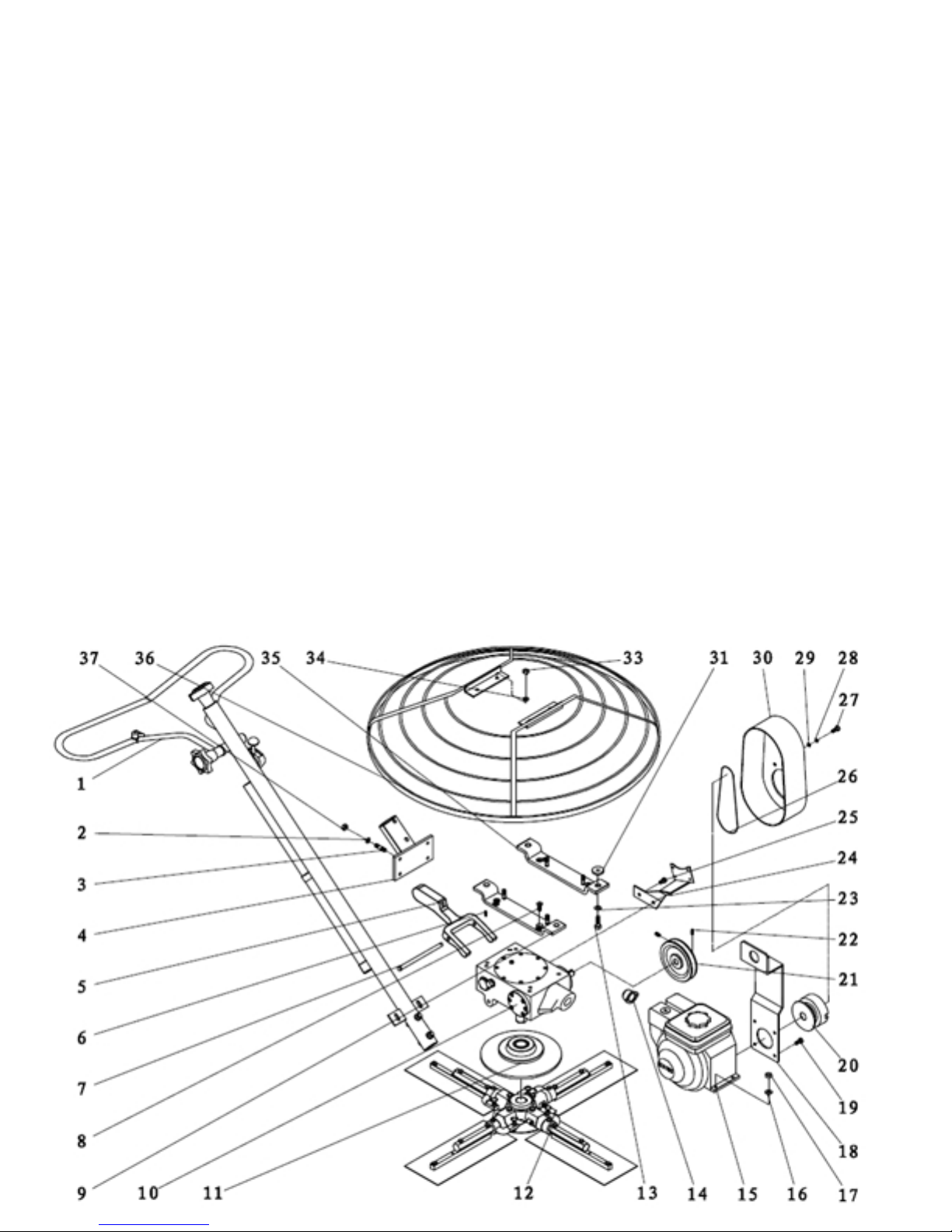

Diagram…………………………..……………………19

FOREWARD

• For your own safety and protection from bodily injuries,

carefully read, understand and follow the safety instructions

in this manual.

• Please operate and maintain your machine in accordance

with the instructions in this manual.

• Defective machine parts are to be replaced as soon as

possible.

• Keep this owner's manual handy, so you can refer to it at

any time.

• No part of this publication may be reproduced without

written permission.

• We expressly reserve the right to technical modications-

even without express due notice - which aim at improving

our machines or their safety standards.

FEATURE

QJM1000 Walk-behind Power Trowel can be used in surface

nishing of concrete road, terrace, boatyard, airport and oor

etc.

Deadman switch design provide safe. A sophisticated system to

protect the operator from an out-of-control spinning handle.

When the operator is using a walk-behind power trowel and

let go of the safety sensor detects the motion of the handle and

stops the engine before the handle reaches a 45-degree rotation.

e handle can be adjusted due to the stature of operator, and it

oers maximum control and comfort for the operation. e alloy

blades which have get heat treatment are worn well. Low center

of gravity provides workers with safe and stable operation.

SPECIFICATION

KPT 36

Weight: 83kg

Diameter: 980mm

Float pan diameter: 945mm

Trowel blade rev: 70r/min~140r/min

Overall diameter: 1820×945×980mm

Blades: 4

Gearbox oil: WA460

Gearbox oil capacity: 950ml

Power output: 5.5hp

Engine type: HONDA GX160

Fuel capacity (L): 3.6

Engine oil type: Recommended

SAE10W-30

Engine oil capacity (L): 0.6

KPT 48

Weight: 119kg

Diameter: 1175mm

Float pan diameter: 1180mm

Trowel blade rev: 70r/min~140r/min

Overall diameter: 2080×1170×1020mm

Blades: 4

Gearbox oil: WA460

Gearbox oil capacity: 950ml

Power output: 9/13hp

Engine type: HONDA GX270/390

Fuel capacity (L): 6/6.5

Engine oil type: Recommended

SAE10W-30

Engine oil capacity (L): 1.1