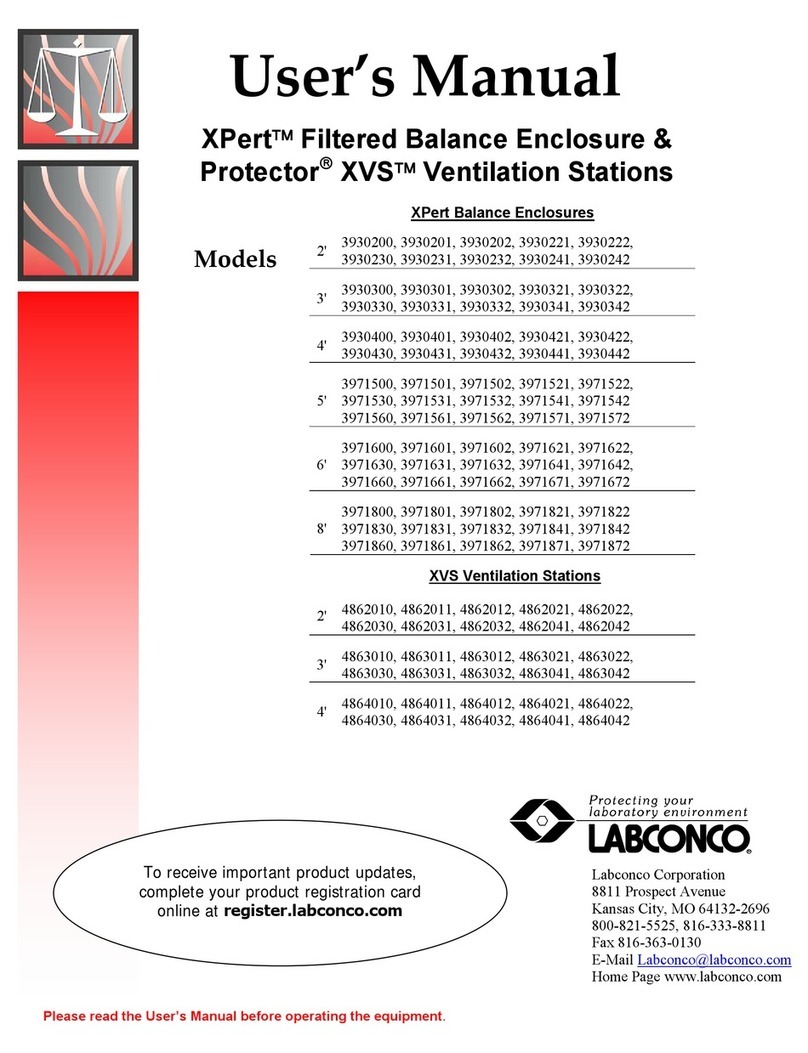

XPertFiltered Balance Enclosures &

ProtectorXVS™Ventilation Stations

Models

3930200, 3930201, 3930202, 3930221, 3930222,

3930230, 3930231, 3930232, 3930241, 3930242

4862010, 4862011, 4862012, 4862021, 4862022,

4862030, 4862031, 4862032, 4862041, 4862042

3930300, 3930301, 3930302, 3930310, 3930321, 3930322,

3930330, 3930331, 3930332, 3930341, 3930342, 3970100

4863010, 4863011, 4863012, 4863021, 4863022,

4863030, 4863031, 4863032, 4863041, 4863042

3930400, 3930401, 3930402, 3930410, 3930421, 3930422,

3930430, 3930431, 3930432, 3930441, 3930442, 3970500

4864010, 4864011, 4864012, 4864021, 4864022,

4864030, 4864031, 4864032, 4864041, 4864042

3971500, 3971501, 3971502, 3971521, 3971522,

3971530, 3971531, 3971532, 3971541, 3971542,

3971560, 3971561, 3971562, 3971571, 3971572

4865010, 4865011, 4865012, 4865021, 4865022,

4865030, 4865031, 4865032, 4865041, 4865042,

4865060, 4865061, 4865062, 4865071, 4865072

3971600, 3971601, 3971602, 3971621, 3971622,

3971630, 3971631, 3971632, 3971641, 3971642,

3971660, 3971661, 3971662, 3971671, 3971672

4866010, 4866011, 4866012, 4866021, 4866022,

4866030, 4866031, 4866032, 4866041, 4866042,

4866060, 4866061, 4866062, 4866071, 4866072

3971800, 3971801, 3971802, 3971821, 3971822,

3971830, 3971831, 3971832, 3971841, 3971842,

3971860, 3971861, 3971862, 3971871, 3971872

4868010, 4868011, 4868012, 4868021, 4868022,

4868030, 4868031, 4868032, 4868041, 4868042,

4868060, 4868061, 4868062, 4868071, 4868072