L&L VENT-SURE DOWNDRAFT KILN VENT INSTRUCTIONS

ventsure-instruct.pdf REV: 8/1/2017 Page 10

©

2017 L&L Kiln Mfg, Inc. 505 Sharptown Rd, Swedesboro NJ 08085 856.294.0077 F:856.294.0070 [email protected] hotkilns.com MOTOR SPECIFICATIONS

120 VOLT MOTOR

PSC Blower, Type:Forward Curve, Direct Drive

Wheel Dia. (In.):3-15/16,Wheel Width (In.):2-1/2

CFM @ 0.000-In. SP:146, CFM @ 0.100-In. SP:140, CFM

@ 0.200-In. SP:126, CFM @ 0.300-In. SP:124. CFM @

0.400-In. SP:120, CFM @ 0.500-In. SP:110,

Voltage:115, Hz:50/60, Phase:1, Full Load Amps:0.75,

RPM:3100

Bearing Type:Ball, Motor Type:Permanent Split Capacitor,

Motor Enclosure:Open, Motor Insulation:Class B, Thermal

Protection:Auto

Lead Length (In.):13, Conduit Box:Yes,

Ambient Temp. (Deg. F):104, Max. Inlet Temp. (Deg. F):104

Inlet Dia. (In.):3-1/8, Outlet Height (In.):2-3/16, Outlet

Width (In.):3-1/4, Overall Height (In.):5-3/4, Overall Width

(In.):6-5/16, Overall Depth (In.):5-3/8, Mounting:All Position,

Housing Finish:Gray Enamel, Housing Material:Rolled Steel

Agency Compliance:UL Recognized US and Canada

(E47479)

220-240 VOLT MOTOR

Item-PSC Blower,Type-Forward Curve, Direct Drive

Wheel Dia. (In.):3-3/4, Wheel Width (In.):1-7/8

CFM @ 0.000-In. SP:133,CFM @ 0.100-In. SP:128, CFM

@ 0.200-In. SP:126, CFM @ 0.300-In. SP:119, CFM @

0.400-In. SP:112, CFM @ 0.500-In. SP:105,

Voltage:230, Hz:50/60, Phase:1

Full Load Amps:0.33, RPM:2880

Bearing Type:Ball, Motor Type:Permanent Split Capacitor,

Motor Enclosure:Open, Motor Insulation:Class B, Thermal

Protection:Auto, Lead Length (In.):13, Conduit Box:Yes,

Ambient Temp. (Deg. F):104, Max. Inlet Temp. (Deg. F):104

Inlet Dia. (In.):3-1/4, Outlet Height (In.):2-1/2, Outlet Width

(In.)2-9/16, Overall Height (In.)6-9/16, Overall Width (In.):5-

5/8, Overall Depth (In.):6-9/16

Mounting:All Position, Housing Finish:Gray Enamel,

Housing Material:Rolled Steel

The Vent-Sure vent is c-MET-us listed in both the US and

Canada for use with L&L listed kilns. UL 499, CSA C22.2,

No. 122, CSA C22. Listing No E112742.

PARTS

Prices of all parts are listed at:

hotkilns.com/parts

Complete Vent-Sure Kiln Vent System

M-V-VENT/00 ................................................................. (see web)

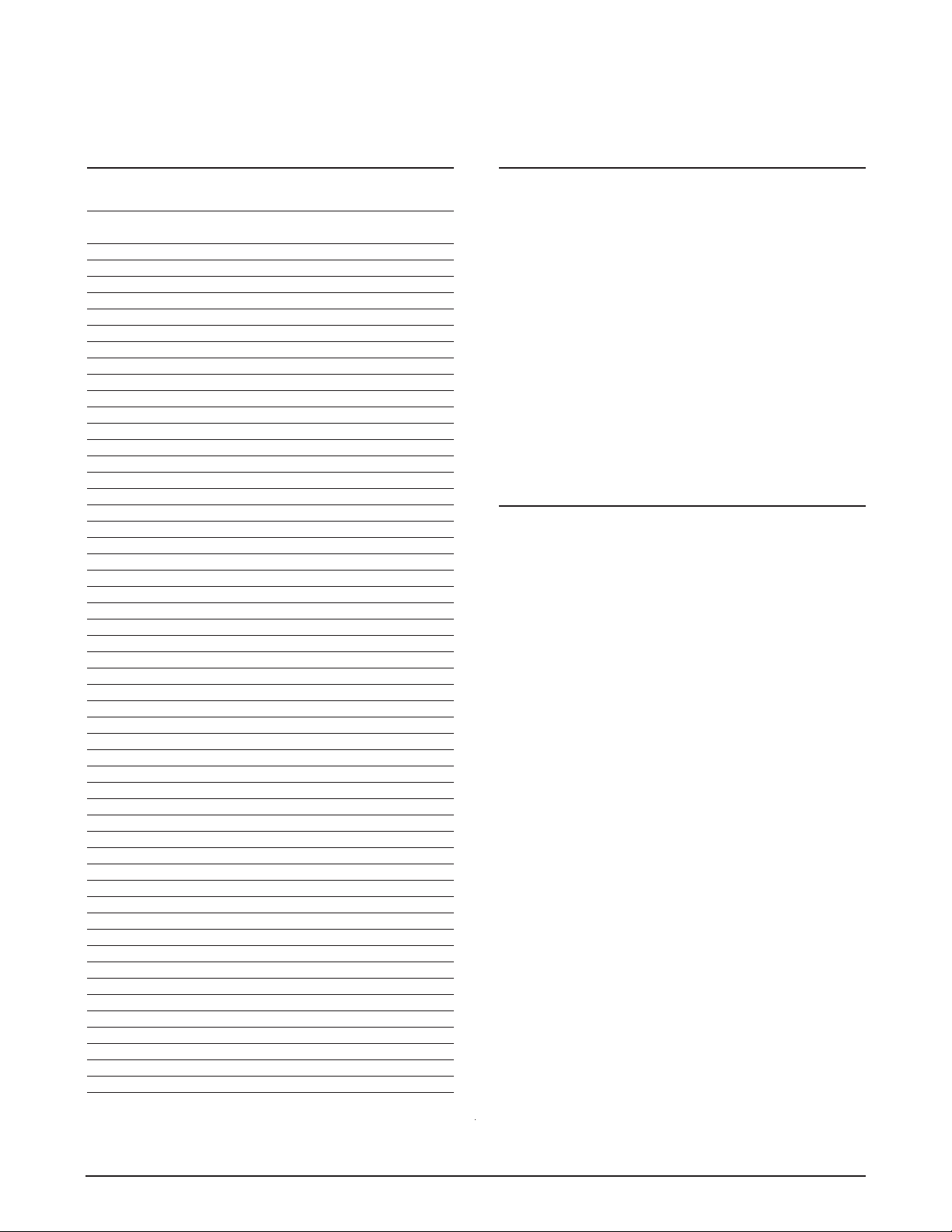

VENT-SURE Vent. 120 Volt. Complete System as described

above and on our separate Vent-Sure brochure. This includes the

motor, an 8 foot cord with a rocker type On/Off switch mounted

in line in the cord, the inlet duct attached to the motor, the wall

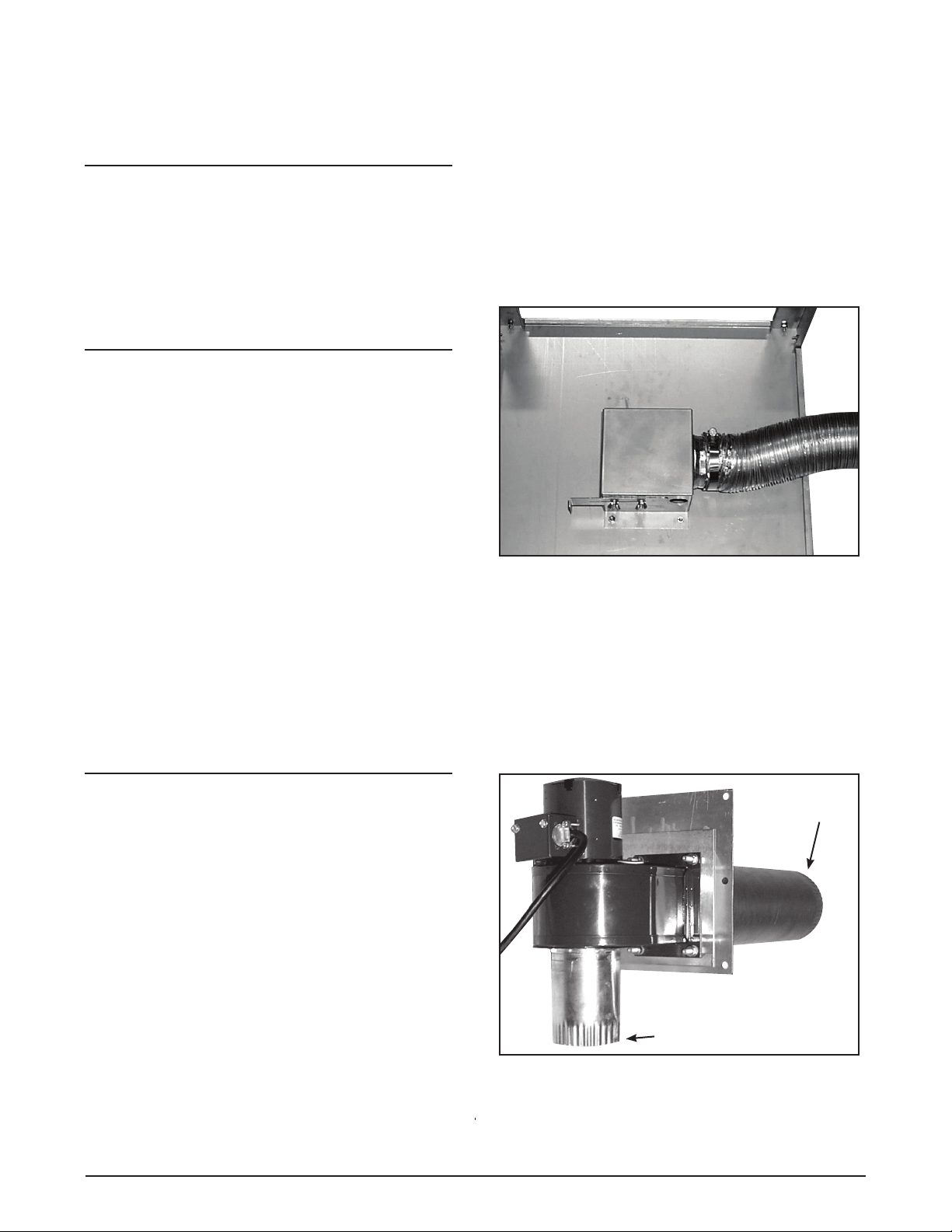

mounting bracket, a 90 deg elbow for mounting on the end of the

outlet pipe (to keep rain water out), the Bypass Collection Box

for attaching to the kiln stand or kiln side along with mounting

hardware for mounting to an L&L kiln stand and one section of 15

foot flexible aluminum duct with hose clamps.

M-V-VENT/41 ................................................................. (see web)

VENT-SURE Vent. 220-240 Volt. Typically used in non-US instal-

lations.

You can also purchase individual parts to suit your

own configuration or as replacements:

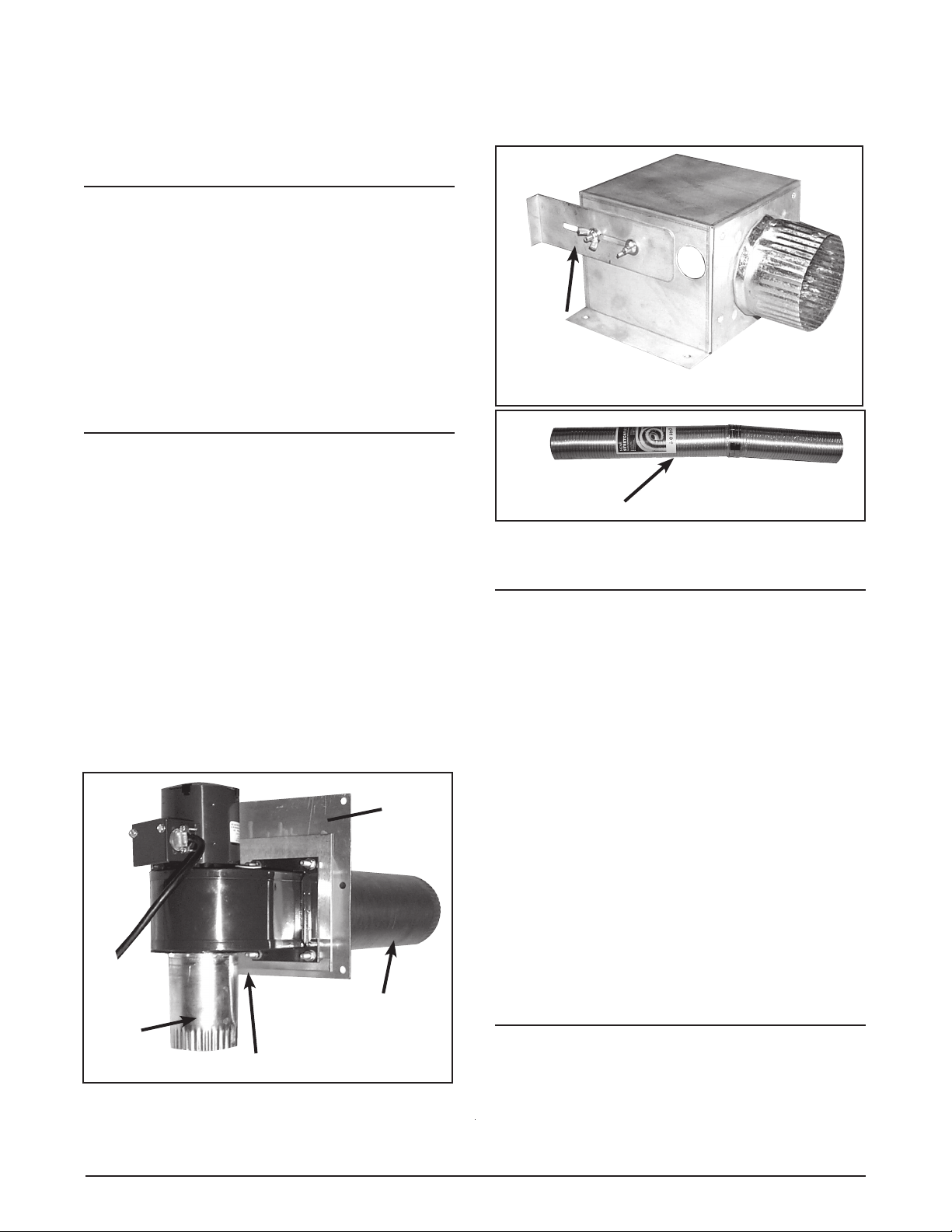

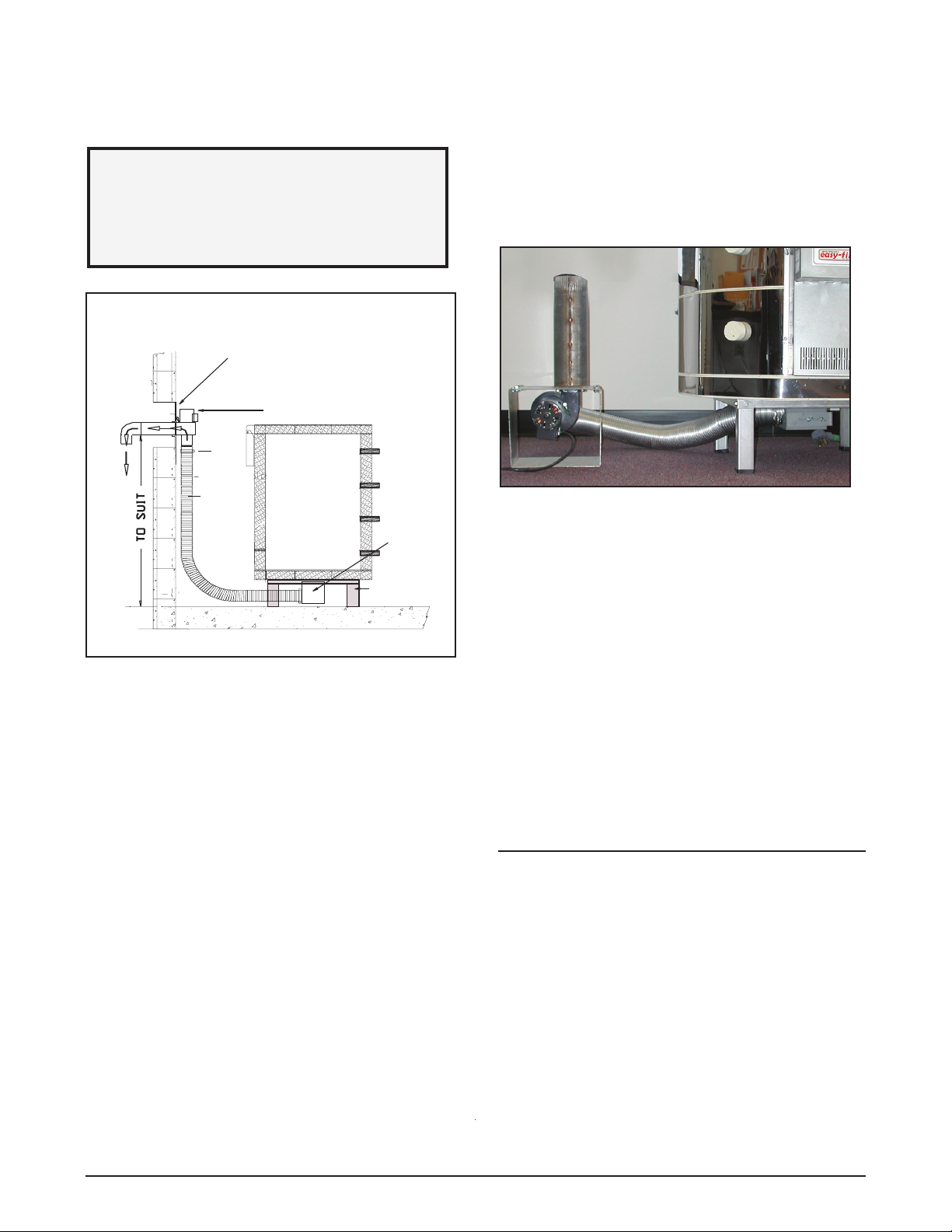

Below shows the vent system blower assembly with the motor,

cord and switch set, 3” inlet duct to hold the flexible duct, 12”

duct to go through a wall and 90 Degree elbow.

M-V-FANK/00..................................................................(see web)

Complete blower assembly. Pictured above ^

M-V-FAN0/00 ................................................................. (see web)

Fan/Blower Motor for Vent-Sure. 120 Volts. This is just the motor

with no attached brackets or inlets. Cord is not included.

M-V-FAN0/41 ................................................................. (see web)

Fan/Blower Motor for Vent-Sure. 220-240 Volts. This is just the

motor with no attached brackets or inlets. Cord is not included.

M-V-BRKT/00................................................................. (see web)

Steel plate onto which the motor mounts. Includes 4” x 12” outlet

pipe and output mounting plate.

M-V-INLT/00....................................................................(see web)

Motor Inlet Duct. This is the piece of duct that attaches to the inlet

of the motor. The expandable aluminum duct fits onto this.