CROSSFIRE Installation & Operations Manual

10 | Page

© 2017, LCO Technologies LTD. All rights reserved. (V5.1)

−Recommendation: Use a filter on the pump inlet, this ensures that no foreign matter particles

get into the fluid ends during chemical injection.

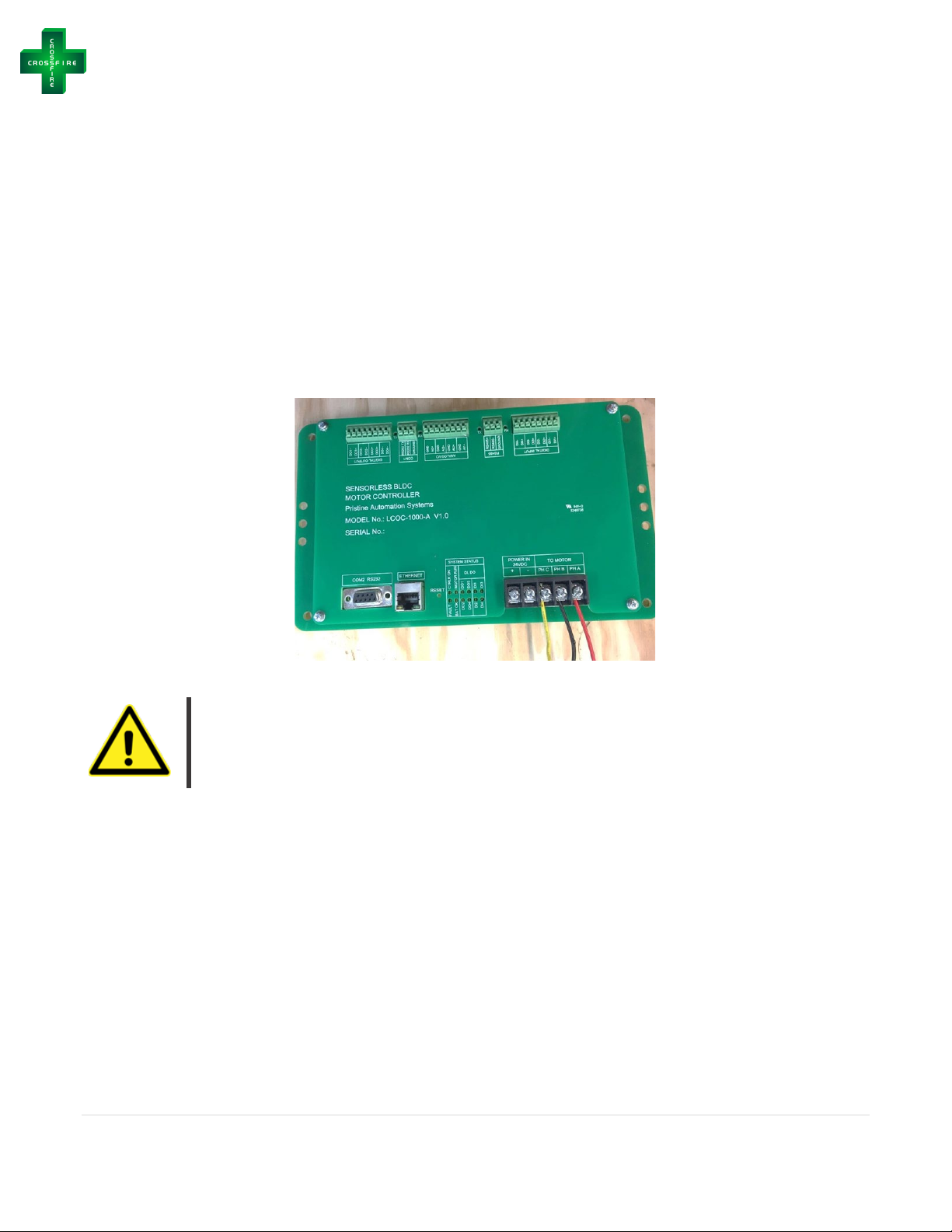

Optional Step: Connect the CROSSFIRE to a SCADA/RTU System

−Connect three 20 Gauge wires to the RS485 terminal blocks on the CROSSFIRE controller.

oRS485+, RS485-, and RS 485 GROUND

−Connect the wires to the SCADA/RTU system

−Install a two-position selector switch on the outside of the NEMA 4 enclosure to ensure

when an Operator is onsite completing maintenance, that the pump can be manually

switched from remote control mode, into local control mode for safety. This switch is

required for safety purposes; all MODBUS registers can be monitored remotely when the

switch is on remote control mode.

oWire the switch to the Digital Input DI1 terminal block on the controller such that 24 VDC

will be on DI1+ when remote position is selected and 0 VDC for the local positioner

−Download and connect to the CROSSFIRE computer software as per the download and

operations instructions on page 14

oLog in as “Technician” for access to all tabs

oGo to “System Setup” panel (picture on page 22)

Set your Slave ID and Baud Rate

Press “Save” button

oGo to “Automation” Tab (picture on page 28)

Select “local remote switch control” from the drop-down menu to enable the two-

position selector switch

Press “Save” button

Label position one and two on the outside of the panel to “local” and “remote”

For all MODBUS register maps and assistance to set up MODBUS, please contact your local

distributor or LCO Technologies directly

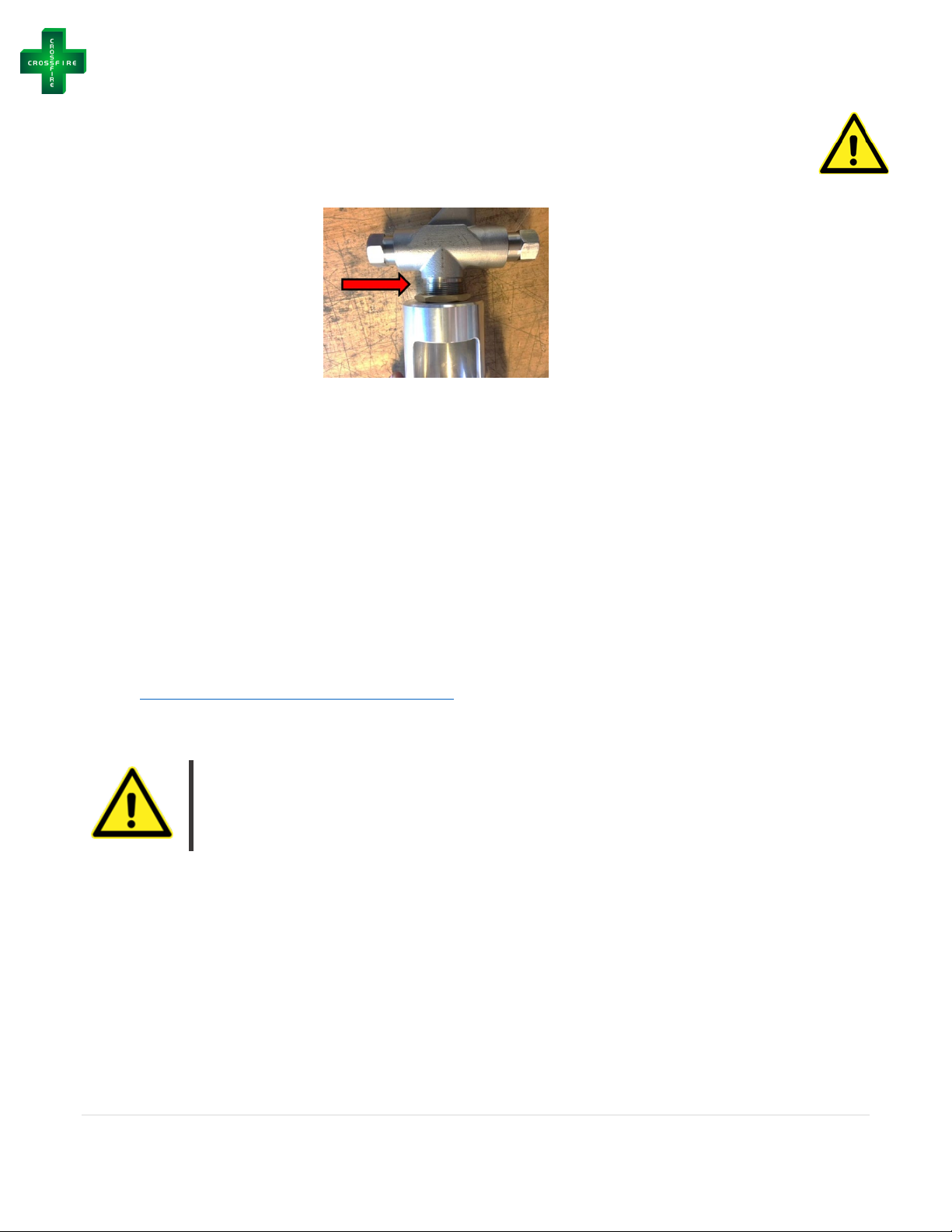

Optional Step: Wire in Motor soft stop switch (non-positive isolation feature)

−If connecting over MODBUS, a C1D2 two-positioner switch may be wired to the controller for a

local “Start/Stop” motor switch. This switch will allow Operators onsite to turn the motor ON or

OFF with an easy switch (no laptop or Bluetooth connection App required) but will not prevent

MODBUS users to view pump parameters remotely as the power to the controller has not been

affected.

−Note: This is not a positive isolation method of stopping the motor, consider this equivalent to

the “start/stop” buttons in the app and laptop software

−Wire the C1D2 two-positioner switch according to the diagram below (next page, page 11):

oApply 24 V to AI3+ and 0 V to Ground

oLabel the switch ON for 24V, and OFF for 0V

−Access the “Terminal Tab” in the software or mobile App and enter command

“setMotorSoftStopEn” to enable function

−Confirm function by entering command “showMotorSoftStopEn”