LCPRO SHARKi User manual

SHARKi

IP66 BEAM Movinglight

User Manual

V1.1

Table of contents

1. SAFETY INSTRUCTIONS..........................................................................................................................................1

2. PRODUCT INTRODUCTIONS...................................................................................................................................3

2.1 DIMENSIONS .............................................................................................................................................................3

2.2 FIXTURE OVERVIEW .................................................................................................................................................4

2.3 ACCESSORIES ...........................................................................................................................................................4

3. PACKING AND SHIPPING.........................................................................................................................................5

3.1 PROTECTION LOCK.............................................................................................................................................5

3.2 UNPACKING ..........................................................................................................................................................5

3.3 PACKING AFTER USE ................................................................................................................................................5

4. INSTALLATION ................................................................................................................................................................6

4.1 CLAMPS INSTALLATION ...................................................................................................................................6

4.2 DEVICE INSTALLATION .....................................................................................................................................6

4.3 LAMP FITTING AND ADJUSTMENT ............................................................................................................................7

5. POWER / CONTROL CONNECTION .................................................................................................................................8

5.1 POWER CONNECTION ................................................................................................................................................8

5.2 CONTROL CONNECTION...................................................................................................................................8

5.3 TESTING.................................................................................................................................................................8

6. CONTROL PANEL ............................................................................................................................................................9

6.1 PANEL INSTRUCTION ................................................................................................................................................9

7. TECHNICAL SPECIFICATION ..........................................................................................................................................10

8. GOBOS AND COLORS.............................................................................................................................................12

8.1 GOBOS..................................................................................................................................................................12

8.2 COLORS................................................................................................................................................................12

9. MENU STRUCTURE .................................................................................................................................................13

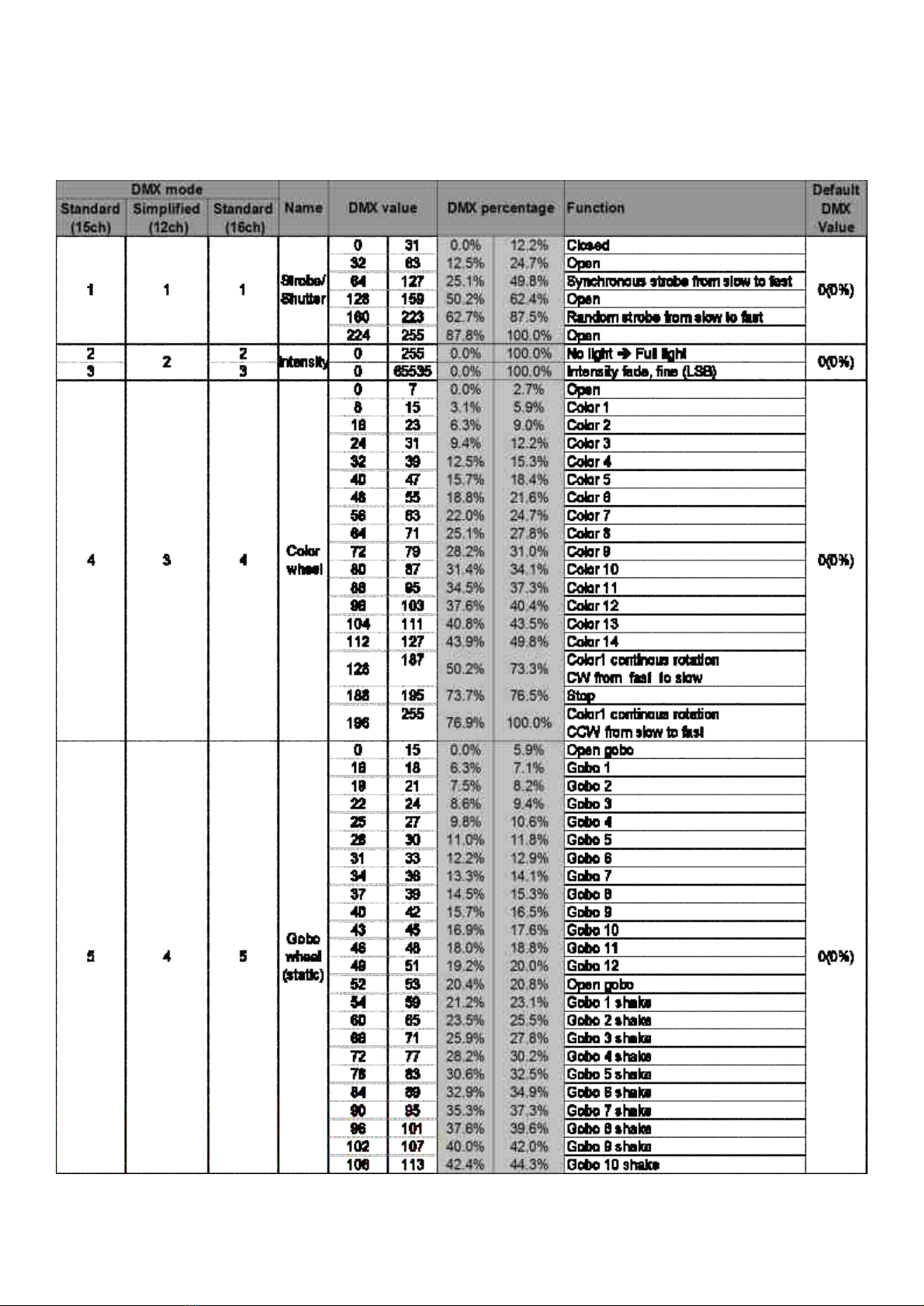

10. DMX PROTOCOL ....................................................................................................................................................16

11. SYSTEM WIRING DIAGRAM ...............................................................................................................................18

12. MAINTENANCE AND TROUBLESHOOTING....................................................................................................19

12.1 CLEANING AND MAINTENANCE.................................................................................................................19

12.2 TROUBLESHOOTING......................................................................................................................................19

1

1.Safetyinstructions

Beforeusingthefixture,readthelatestversionoftheproductusermanual,payingparticularattentionto

thesafetyinstructions.

m

ta

tc

The manufacture of this fixture, are not responsible for damages, resulting from misuse of this

fixture,duetothedisregardoftheinformationprintedinthisusermanual.

DANGER!

Hazardousvoltage.Riskoflethalorsevereelectricshock

WARNING!

Wearprotectiveeyewear.Neverlookdirectlyintothelightsource.

WARNING!

Burnhazard.Hotsurface.Donottouch.

Onlytodirectmountingonnon-combustiblesurfaces.

Minimumdistancetolightedobjects.

Replaceallcrackedglassshields.

Maximumambienttemperature.

Maximumtempoftheexternalsurface.

2

General guidelines

lThis product has a protection rating of IP66.

lNever open this fixture while in use.

lThe fixture should be kept clean. DO NOT operate the fixture in extreme heat or dusty environments. Avoid contact

with chemical liquid.

lMinimum distance to lighted objects must be 49.21feet (15m).

lMaximum temp of the external surface 194˚F (90˚C).

lMaximum ambient temperature 113˚F (45˚C).

lMinimum distance of inflammable materials from the surface 1.6 feet (0.5m).

lLamp should be changed if damaged or distorted in shape due to extreme heat.

lCover, prism or LCD Menu Function Display with visible damages such as cracks or scratches must be replaced to

ensure performance of the fixture.

lDisconnect the fixture from power before changing any parts or accessories.

lBasic insulation should be maintained between the controllable device and the product power supply.

lMake sure that the installation area can hold a minimum point load of 10 times the weight of all installed

fixtures, clamps, cables, auxiliary equipment, etc. Check that the cover, clamps and locks are undamaged. Certified

safety cables must always be used when installing the fixture.

lThe fixture is only intended for installation, operation and maintenance by qualified professional. Instructions stated in

the manual must be complied.

lThe fixture must be kept in a well-ventilated place at least 50 cm away from any wall surface. Check if the fans or

ventilation openings are unblocked.

lThis fixture uses discharge lamp. To avoid reducing the lamp’s life, wait at least 15 minutes after powering off to allow

the unit to cool down before handling.

lBroken or damaged cables and light source can only be fixed or changed by certified technicians, certified local

distributors or the manufacturer to ensure operational safety.

lDo not stick filters or other materials onto the lens. Do not modify the fixture or install other manufactured parts.

3

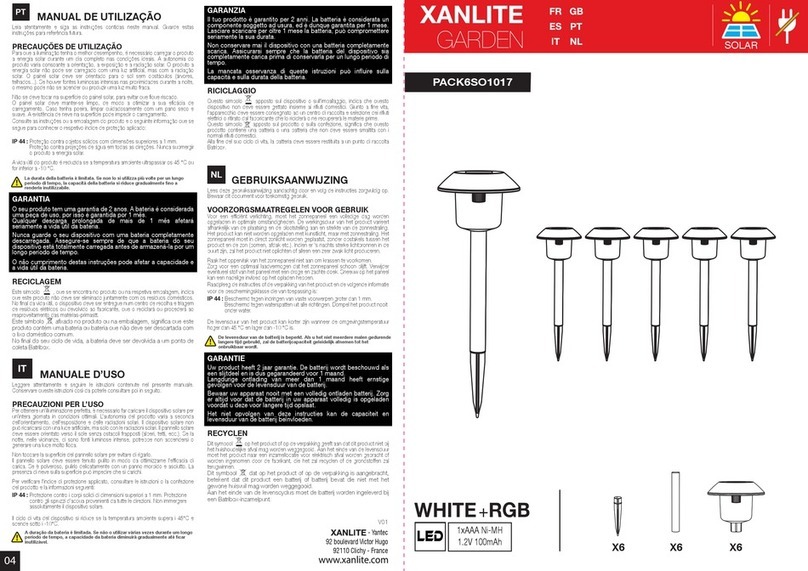

2. Production instructions

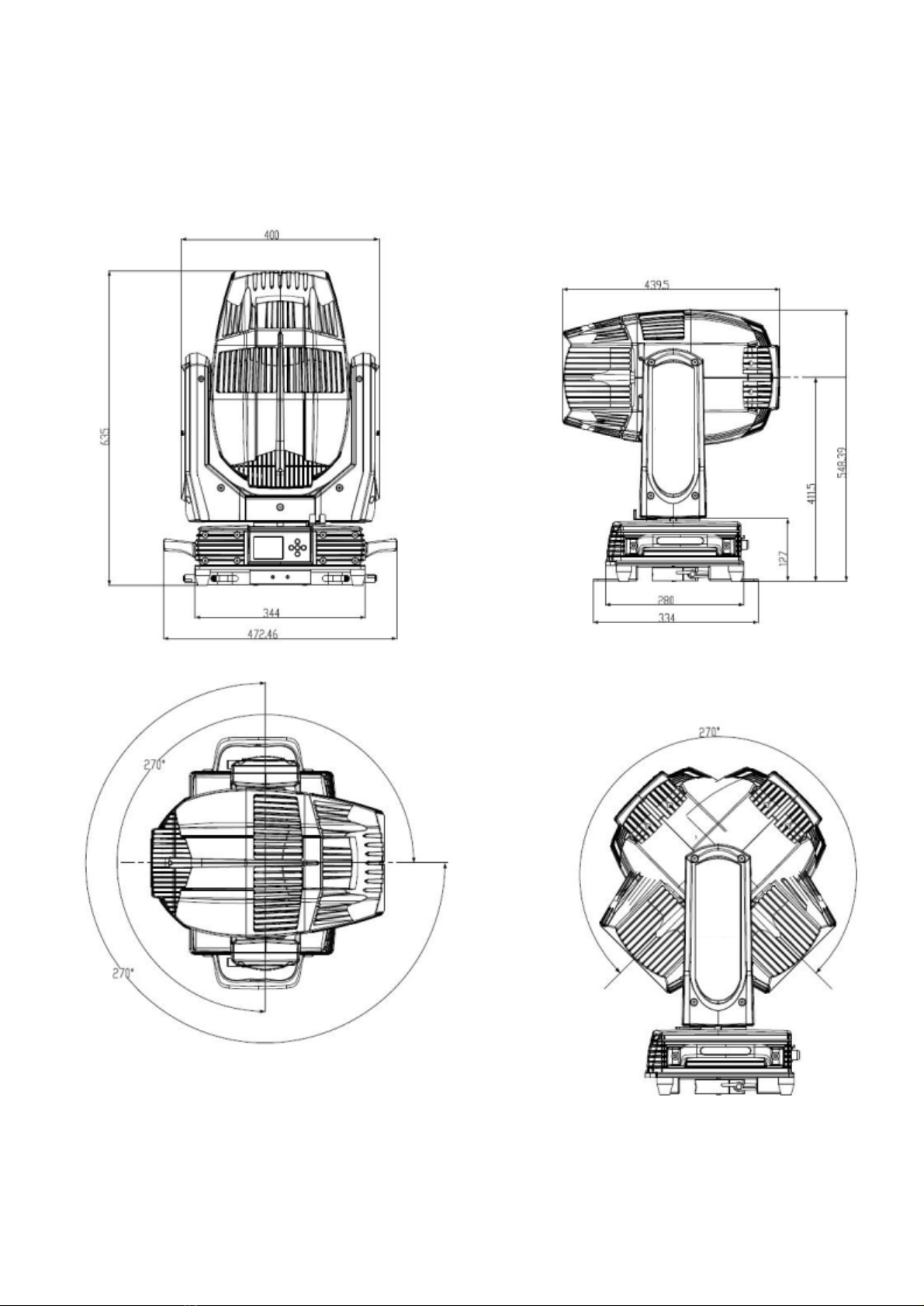

2.1 Dimensions

4

2.2 Fixture overview

2.3 Accessories

Item Qty Unit Remark

User Manual 1 Pc --

Clamps 2 Set Hanging integrated folding lamp, Load weight 200KG

Safety cable 1 Pc Φ5*60cm 7*19 pc with hook Material:Steel

5-pins signal line 1 Set --

Power cable 1 Set 1.5*2.5mm2

5

3. Packing and shipping

3.1 Protection lock

Pan and tilt locks are equipped to ensure safe transportation.

PAN: 4 lock positions are located evenly on the Pan.

3.2 Unpacking

Notes

All products are quality controlled and checked for any faults before they are dispatched to customers. If the fixture is

damaged during delivery, the customer must notify the shipper and manufacturer to file a damage insurance claim.

Photographic evidence of the damage must be provided.

Flight-Case:Open the cover of the flight-case and remove the plastic packing bags. Hold the handles of the fixture firmly

and take it out carefully.

Cardboard box:Open the box and take out the whole set of packaging foam which contains both the fixture and its

accessories. Remove the foam from the top, put away the accessories, and then take out the fixture wrapped in the plastic

bag.

Notes

Check if the pan and tilt are unlocked before connecting the fixture to power.

3.3 Packing after use

1. Switch off the fixture and wait for at least 5 minutes before disconnecting it from AC power. Cool down the fixture for

at least 15 minutes before packing.

2. Lock pan and tilt.

3. Flight case: Wrap the fixture in plastic bags. Hold it by the handles, and then carefully place it inside the flight case

along with all the accessories. Close the cover. Only 3 layers are allowed when piling up the flight cases. Do not upside

down.

4. Cardboard box: Wrap the fixture in plastic bags. Put it in the packaging foam along with all the accessories. Place the

other set of packaging foam on top then carefully put it inside the cardboard box.

水平保

护锁

P a n l o c k

6

4. Installation

4.1 Clamps installation

The fixture can be placed on the stage or mounted on the truss facing any direction. Attach the clamps to the mounting

position on the base of the fixture.

Warning:Use two clamps when mounting the fixture. Turn the screws attached to each clamp a 1/4 turn clockwise to lock.

Always remember to use the safety cable which goes through the mounting hole on the base. Do not attach the safety cable

on the handle.

4.2 Device installation

1. Make sure there is no damage on the clamps or safety cables before installation.

2. The clamp is mounted on the chassis of the fixture. Horizontally insert the clamp into the mounting holes of the chassis.

Fasten the clamp tightly by a 1/4 turn clockwise. Fix another clamp in the same way.

3. Check if pan is unlocked before connecting the unit to AC power.

7

4.3 Lamp fitting and adjustment

1. Disconnect the fixture from AC power. Cool down the fixture. Set the Tilt lock in a horizontal position.

2. Remove the lamp holder lower cover and plug out the waterproof terminal when disassemble the bulb, then loosen the

fixed plate and take out the bulb.

3. Put the bulb into the fixed plate, then press the bulb clockwise with the fixed plate when install the bulb, observe the bulb

spot and adjust it after lighted the bulb. Finally, plug in the waterproof fan and lamp holder lower cover.

Note

The fixture is equipped with PHILIPS MSD Platinum Flex 300S, which is featured with high efficiency and short-arc

characteristic, such as a stable 7200K color-temperature and average lifespan of 6000h.

Note

1. Fitting another type of lamp will cause potential damage to the fixture. Change the lamp before it reaches its lifespan.

Read the guidelines in the package carefully when fixing the lamp.

2. To avoid any impact on the beam, do not touch the bulb with your bare hands. The lamp must be kept clean with the use

of the clean paper contained in its package

Push the light bulb to the

hole,press it down

Enlarged

Remove the back

Back cover

Back cover

cc

8

5. Power/ Control connection

5.1 Power connection

Connection method:

ŸL (Live) Brown wire

ŸE (Earth) Yellow / Green bi-color wire

ŸN (Neutral) Blue wire

ŸThe voltage and frequency of the power source must be in compliance with the ones marked on the fixture. It is

strongly recommended that each fixture are to be connected to the power source separately so that they can be

switched on / off individually.

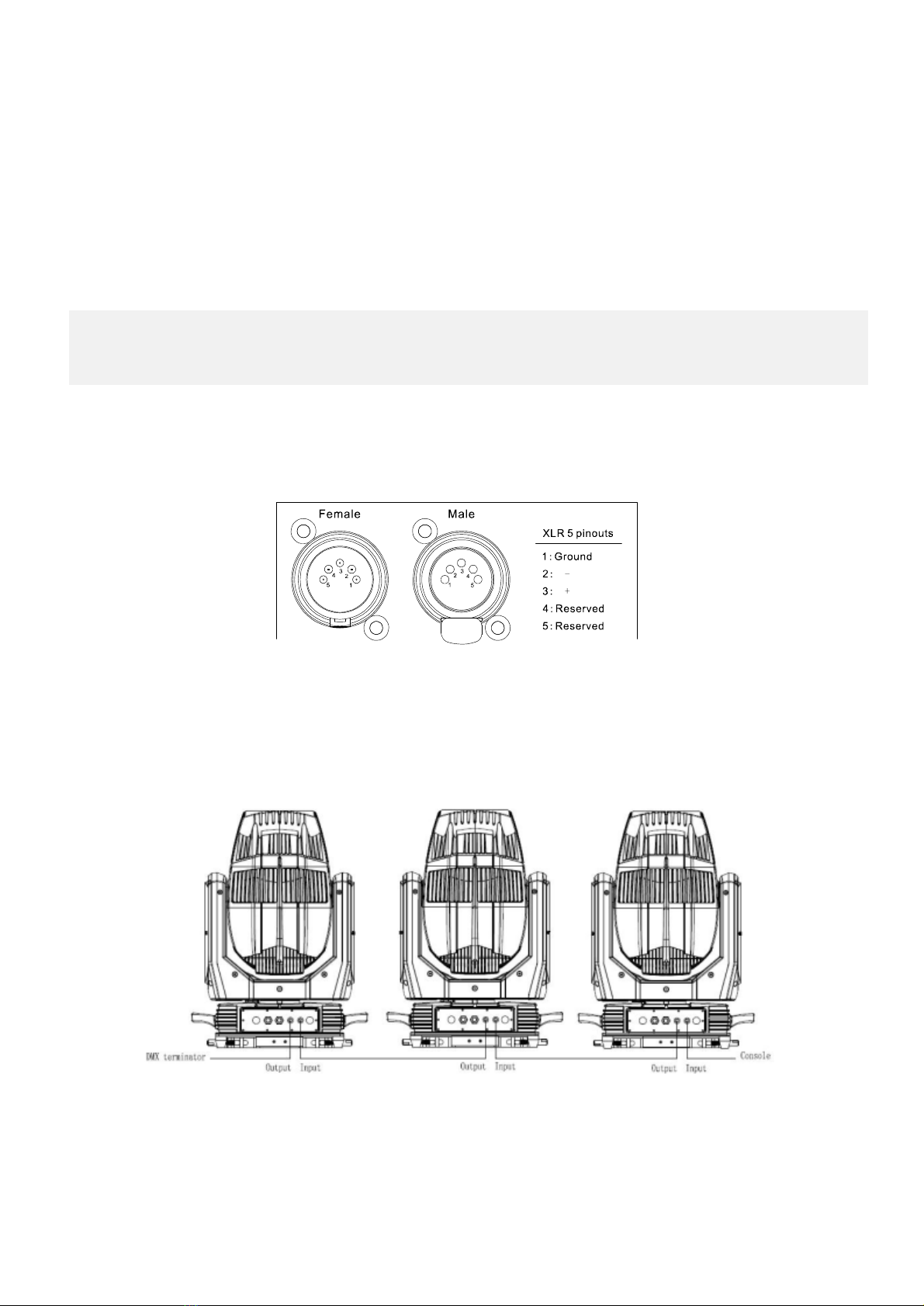

5.2 Control connection

The fixture has 5-pin XLR connectors for DMX data input and output as shown below. Connection between the console and

fixture, and between fixtures must be made with 2 core screened DMX signal cable. Maximum connecting distance of

signal cable is 150 meters. Additional DMX512 signal-amplifier is recommended for longer distance

Connect the Console’s DMX OUTPUT to the first fixture’s DMX INPUT, then the first fixture’s DMX OUTPUT to

the second fixture’s DMX INPUT and so on. It is recommended not to connect more than 32 units on a single

DMX universe. On the last fixture’s output connect a DMX terminator. (The terminator is a 5-pin XLR connector

with a 1/4W and 120Ωresistor between the pin 2 and pin 3) as shown below:

5.3 Testing

Connect the fixture to AC power. Check if the lamp is on and the fixture is independently controllable before

putting into operation.

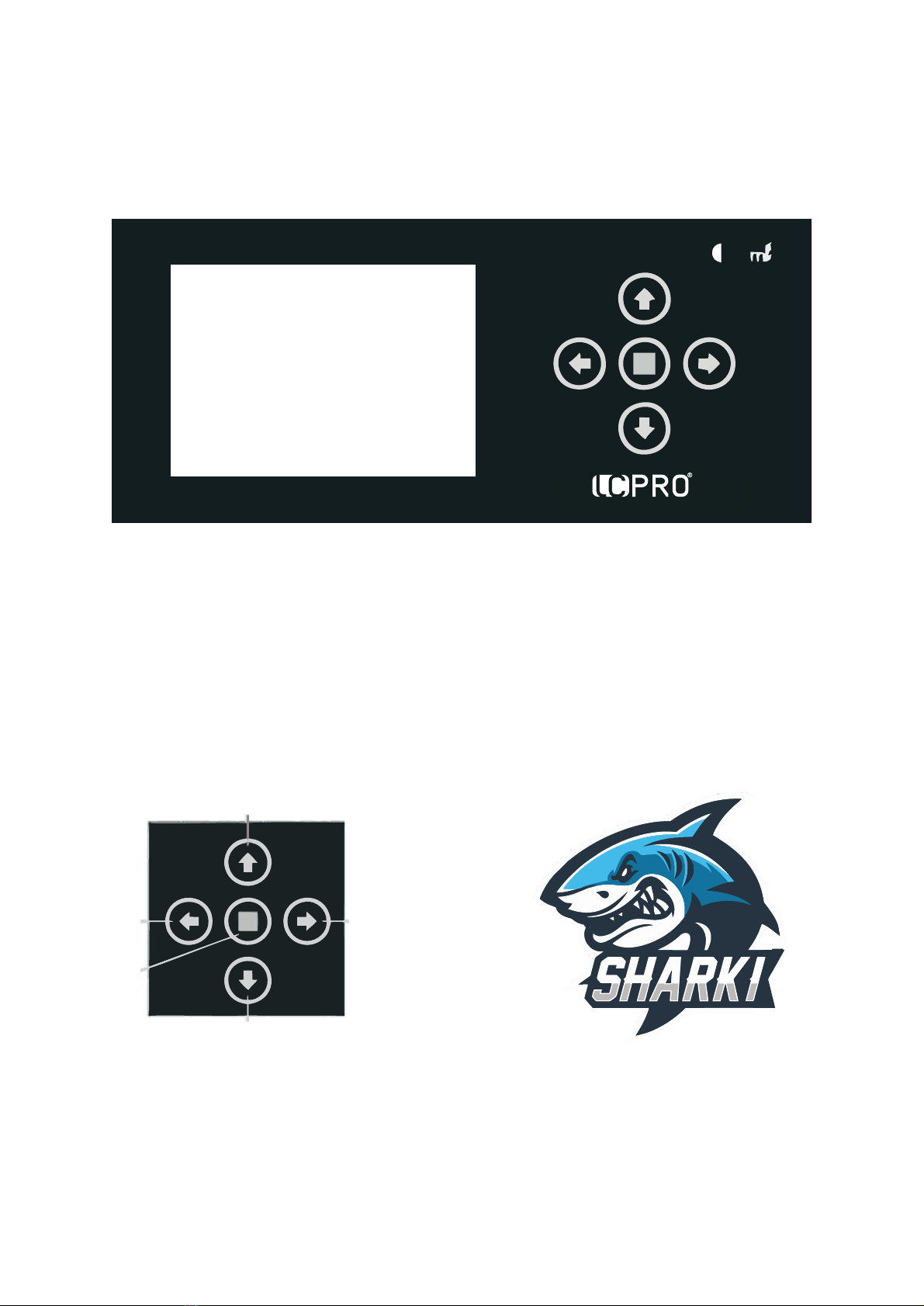

The control panel features touch-sensitive buttons and LCD digital display for quick and easy setup of address code

and functions menu.

Press UP or DOWN to view or select the function menu.

Press CNTER to choose a function and enter into corresponding sub menu. Each menu represents a specific function

of the fixture.

Press RIGHT to select the specific function and save the changes or enter into the submenu, then press UP or DOWN

to change the value of the selected function (increase or decrease).

Press RIGHT to return to the previous menu or exit.

Button panel indicator:

9

6.Controlpanel Panelinstruction

6.1

Upper

Left Right

Middle

Lower

10

7. Technical specification

lOptical

Light source: PHILIPS MSD Platinum Flex 300S

Expected average lifetime: 6000 h

Color temperature correction: 7200K

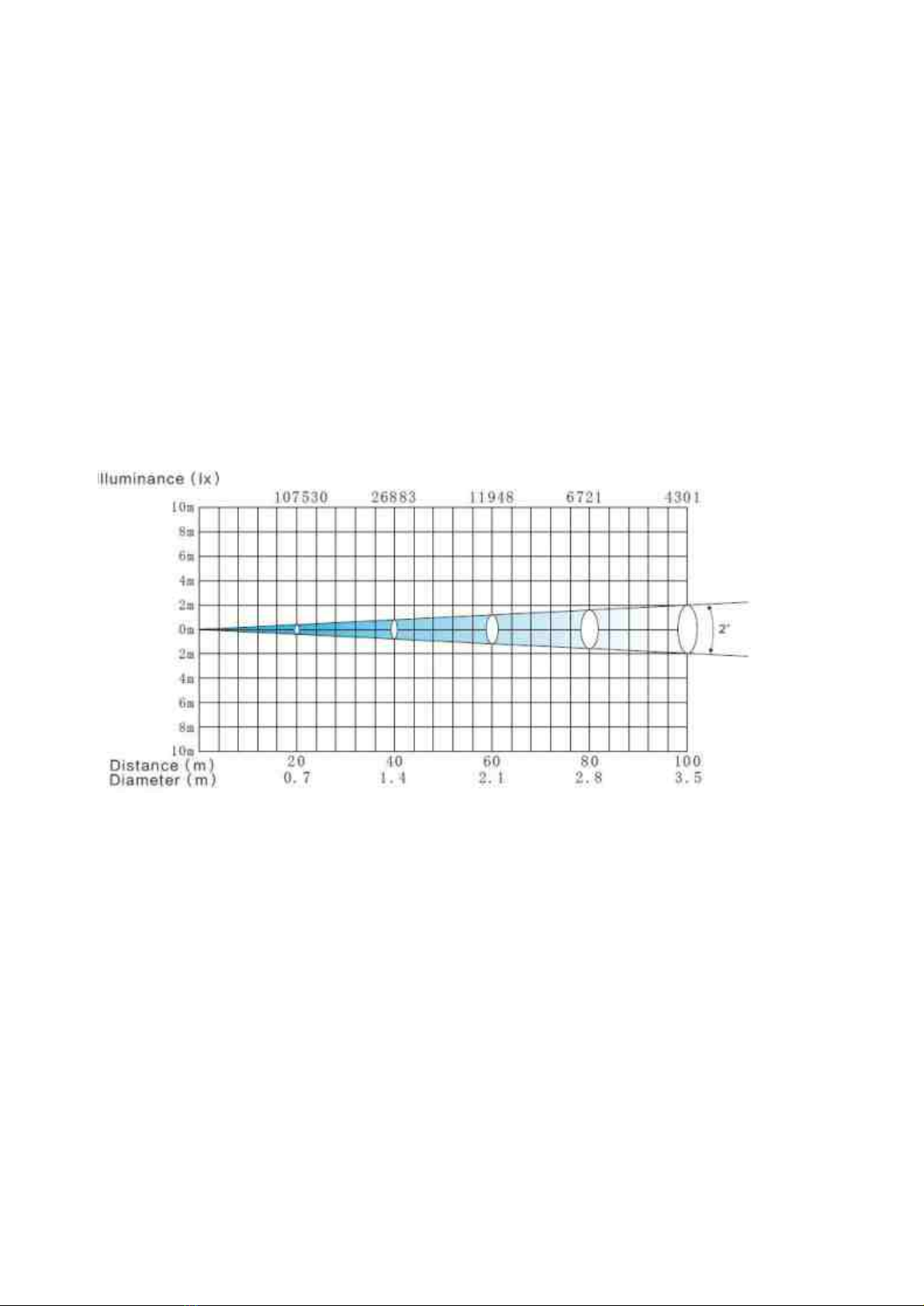

Zoom: 2°

CRI:Ra≥80

Focus: High-precision glass lenses, electronic linear HD focus

Prism: 1 pc tip 8-facet prism,1 pc tip 16-facet prism, prims can be controlled independently ,

or can be combined to make abundant beam effects

Frost: 1-independent frost effect

lGobo

Fixed gobo wheel: 12 gobos + open,CW/CCW rotation, variable speed

lColor

Color wheel: 14 colors + open, split color, CW/CCW rotation, “Rainbow effect” in both directions

lElectrical

Power input, nominal: AC 100-240V 50/60Hz

Max. Power consumption: 580W, max current: 2.9A, PF: 0.99

Power supply unit: Auto-ranging electronic SMPS

Main fuse: 250V/6.3A

Ballast: Electronic

Power input: Self-contained power cord

DMX data input/output: Chassis 5-pin (in/out)

lControl and programming

Control channels (DMX): 15/12/16

Protocol: DMX-512 RDM

Display: LCD

lPhysical / Installation

Weight: 24Kg (52.9lbs.)

IP rating: IP66

Material: Aluminum, steel, plastic

Mounting points: Four quarter-turn locking points + attachment points for safety wire

lDynamic effects

Pan/Tilt movement: 540˚/270˚

Iris: Motorized adjustable iris, wide range of variable pulse effects

Strobe: 1-20Hz, synchronized, pulse effects

11

Dimmer: 0-100%, mechanical dimming

lThermal

Operating range: 5˚F to 113˚F (-15˚C to +45˚C)

Startup range: -13˚F to 113˚F (-25˚C to +45˚C)

Storage range: -40˚F to 140˚F (-40˚C to +60˚C)

Cooling: Active fan

lCertification and Safety

EMC: EN 55103-1:2009, EN 55103-2:2009, EN 61000-3-2:2006+A2:2009, EN 61000-3-3:2013,

GB/T 17743-2007, GB 17625.1-2012

Safety: EN 60598-2-17:1989/A2:1991, GB 7000.1-2015, GB 7000.217-2008

lPhotometric

lOther features

ØEnhanced stability of the fixture due to the wide input voltage AC/DC switching power supply which both reduces the

impact of power and voltage fluctuations, and removes the restriction of voltage and frequency variations in different

countries.

ØAutomatic energy saving: when the shutter or CMY is closed, power consumption will be reduced automatically with

the photoelectric tracking induction technology.

ØSleep mode: uses the most advanced technology to remotely activate sleep mode. When the fixture is disconnected

from signal, the sleep mode is enabled automatically to make it more stable and safer. Sleep time can be customized.

ØPower setting: built-in continuous rechargeable battery, allowing setting functional data via LCD interface without

power connection

12

8.Gobosandcolors

8.1Gobos

Onefixedgobowheel:12gobos+open,CW/CCWrotation,variablespeed

Fixedgobowheel

8.2Colors

Colorwheel:14colors+open,splitcolor,CW/CCWrotation,“Rainboweffect”inbothdirection

1.Red 2.Yellow 3.Blue 4.Yellow

green

5.Purplishred 6.Lightyellow

7.Bluegreen 8.Green 9.Rosered 10.Lavender 11.Fluorescence 12.Claybank

13.Brown 14.Coolwhite

13

9. Menu structure

Level

1Level 2 Level 3 Level 4 Info

1.Run

setting

1.Address Setting

2.Value Display

3.Auto-Program

Address: 001~ XXX

Pan ……,All,Off

Master /Alone

Setting the DMX address

Display the channel value

Run auto program in master or

slave

2.Device

Info

1.Time Info 1.This Time

2.Total Time

3.Last Run Hours

4.Lamp On Hours

5.Lamp Off Hours

6.Time Password

7.Clear Last Run

8.Lamp Time

Password

9.Clear Lamp Time

XXXXXX Hour

XXXXXX Hour

XXXXXX Hour

XXXXXX Hour

XXXXXX Minute

Password: XXX

Yes/ No

Password: XXX

Yes/ No

Since power on time

Product total run time

Last product run time

Lamp on time

Lamp close time

Clear last time password

Clear last time

Clear lamp time password

Clear lamp time

2.Temperature Temperature1 XXX ’C/’F Body temperature

2.Fans Info. NO/...

4.Err Info No Err/... Show this device’s status

5.Software Version V1.0 RDM Code 0032-xxxxxx The software version

3.System

Setting

1.Status Setting 1.Console Set

Address

2.No Signal Status

3.Pan Reverse

4.Tilt Reverse

5.Pan Scan Degree

6.Scan Feedback

7.Standby Time

Enable/Disable

Close/Hold/Auto

Enable/Disable

Enable/Disable

360/540

Enable/Disable

Disable/1~120 Min,

30

Address can be changed by console

The status while no signal

Pan Reverse

Tilt Reverse

Pan Scan Degree

Scan Feedback

Standby time

2.Fan Speed 1.Smart Control

2.High Speed

3.Low Speed

Auto fans speed

Fans high speed

Fans low speed

3.Display Setting 1.Backlight Time

2.Keyboard Lock

3.Brightness Set

4.Language

Select

1~80 Min/Disable

Enable/Disable

15~100% 80%

Chinese/English

Backlight off time

Press <menu> 3s to unlock

Back lightness of screen

Change the language

14

5.Auto Screen Set Off/On/Auto Screen change Setting

4.Temperature Unit Celsius

Fahrenheit

Temperature unit

5.Value Default Pan…… Pan =XXX The default value after power on

6.Wireless Devi Wireless Off

Wireless On

Wireless Trans.

Wireless Reset

Wireless off

Wireless on

Wireless transfer DMX data to

another

Wireless reset

7.Restore Default Yes/No Restore to default value

5. Moto

Reset

1.System Reset

2.Scan Reset

3.ColorReset

4.Gobo Reset

5.Strobe Reset

6.Other Reset

System reset

Pan and tilt motor reset

Color motor reset

All gobo motor reset

Strober motor reset

All other motor reset

6.Chann

el

Adjust

1.Test Mode Pan…… Every channel test

2.Manual Mode Pan

:

Pan =XXX

:

Manual control

3.Adjust Mode Input Password

Pan

:

Password=XXX

Pan=XXX

:

The password of adjust mode

Fixed all begin position

7.Chann

el

Setting

1.Channel Mode Standard Mode

Basic Mode

Extended Mode

Custom Mode A

Custom Mode B

Custom Mode C

Standard channel mode (15ch)

Basic channel mode (13ch)

Extended channel mode (17ch)

Custom channel mode A

Custom channel mode B

Custom channel mode C

2.Set Custom Mode1

3.Set Custom Mode2

4.Set Custom Mode3

Max Channel

Pan

:

Channel = XX

Pan = CH01

:

Change the channel order

8.Progra

m Edit

1.Select Group 1.Program Unit 1 Auto-Program 1 ~10 Choose build-in program for slave

1

2.Program Unit 2 Auto-Program 1 ~

10

Choose build-in program for slave

2

3.Program Unit 3 Auto-Program 1 ~ Choose build-in program for slave

15

*Sengs hight lighted in light grey are default values

10 3

2.Program Edit Auto-Program1

:

Auto-Program10

Run

Step 1=Scene xxx

Step 8=Scene xxx

Choose the scene for program 1

:

Choose the scene for program 10

3.Scene Edit Scene Edit:001-250 Pan,……Pan=xxx

Scene Time=xxx

Input By Console

Edit the channel DMX

Edit the scene time

Get scene DMX form console

4.Record Scene Start Scene: XX Start Scene: XX

End Scene: XX

Record scene form console

16

10. DMX Protocol

17

18

11. System wiring diagram

Table of contents

Other LCPRO Lighting Equipment manuals

Popular Lighting Equipment manuals by other brands

Vision & Control

Vision & Control DL30x30-R633/24V Instructions for use

Isolite

Isolite ELT2.0 ELITE Series Installation and operating instruction

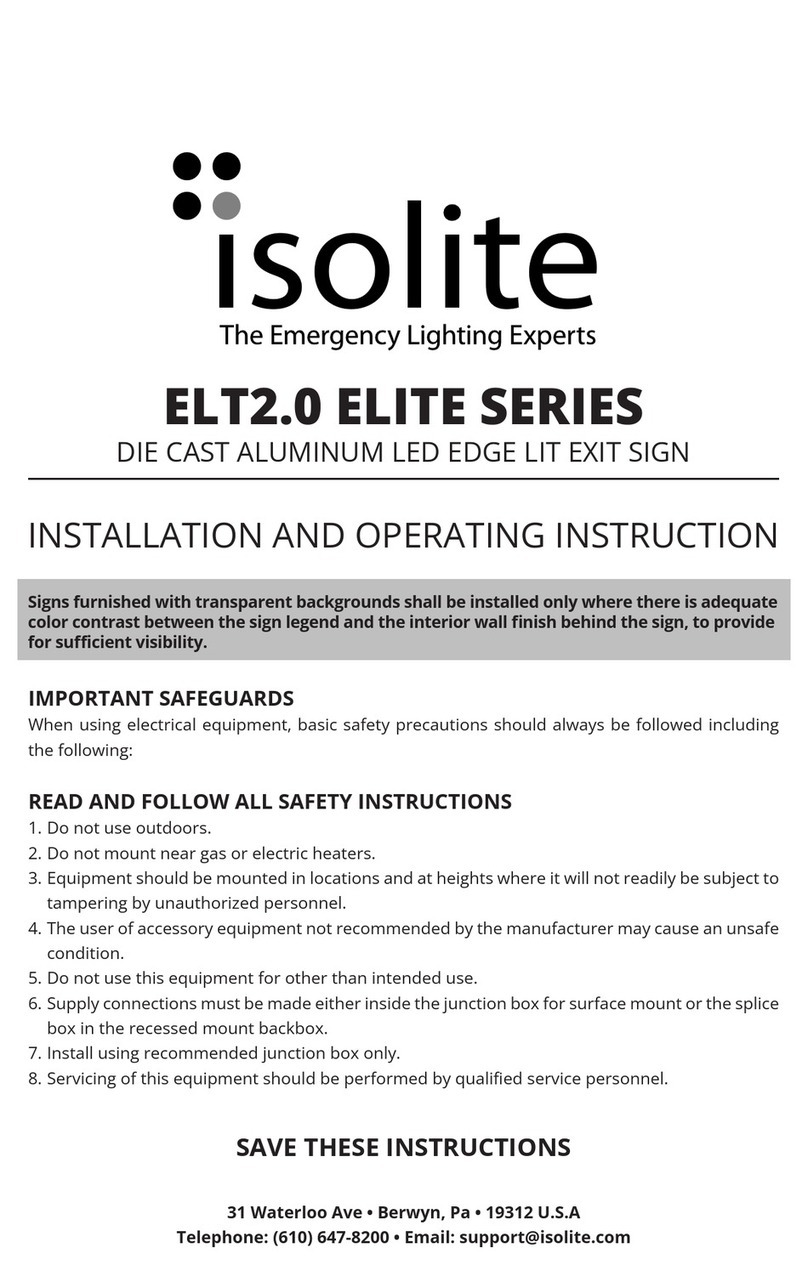

batt led

batt led NEONFLEX installation guide

Cooper

Cooper HALO L2702 installation instructions

XanLite

XanLite PACK6SO1017 quick start guide

Varytec

Varytec Easy Move XS HP Wash user manual