Installation

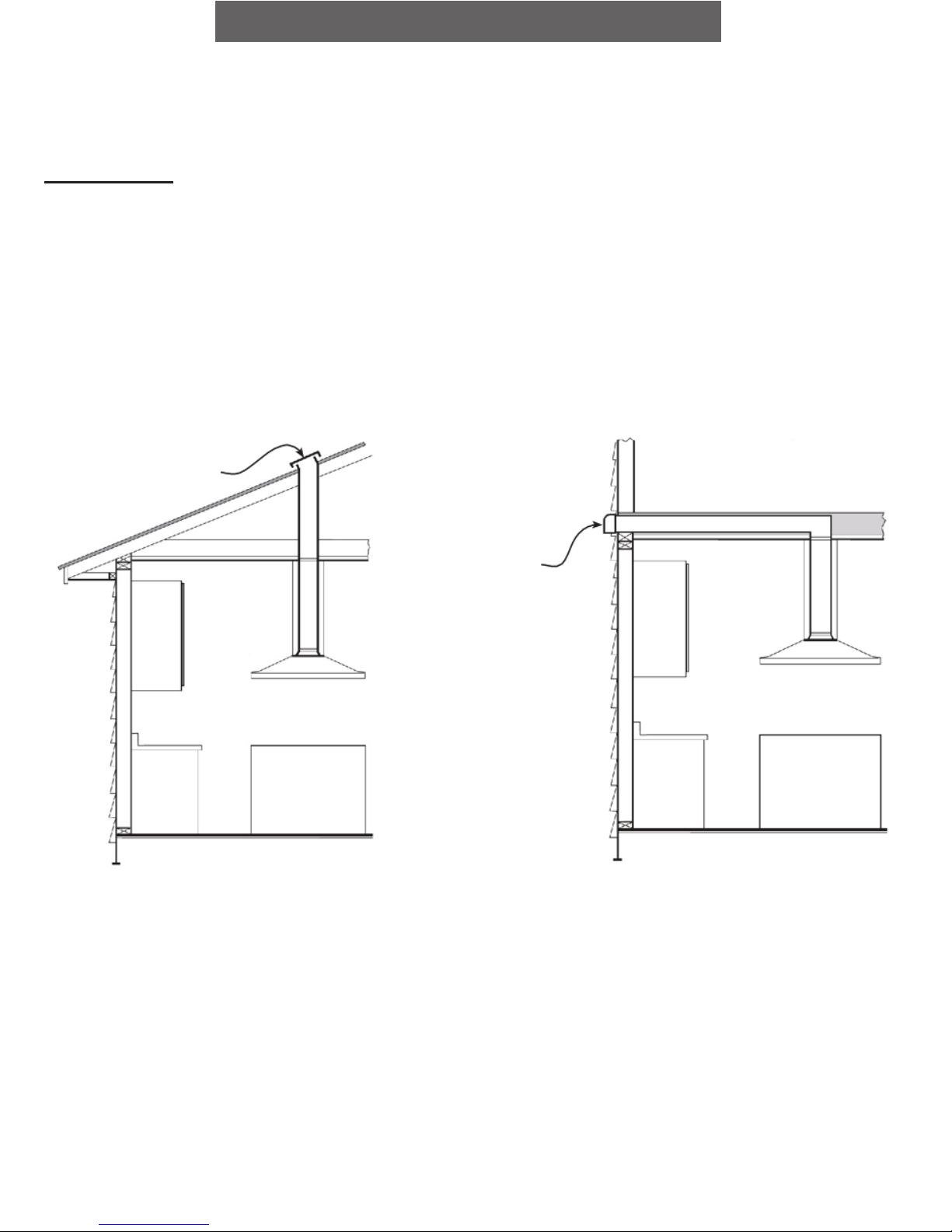

• Vent system must terminate to the outside (roof

or side wall).

• DO NOT terminate the vent system in an at- tic

or other enclosed area.

• DO NOT use 4” (10.2 cm) laundry-type wall

caps.

• Use metal /aluminum vent only. Rigid metal

(Not Included).

aluminum vent is recommended.

• DO NOT use plastic vent.

•Always keep the duct clean to ensure proper

airflow.

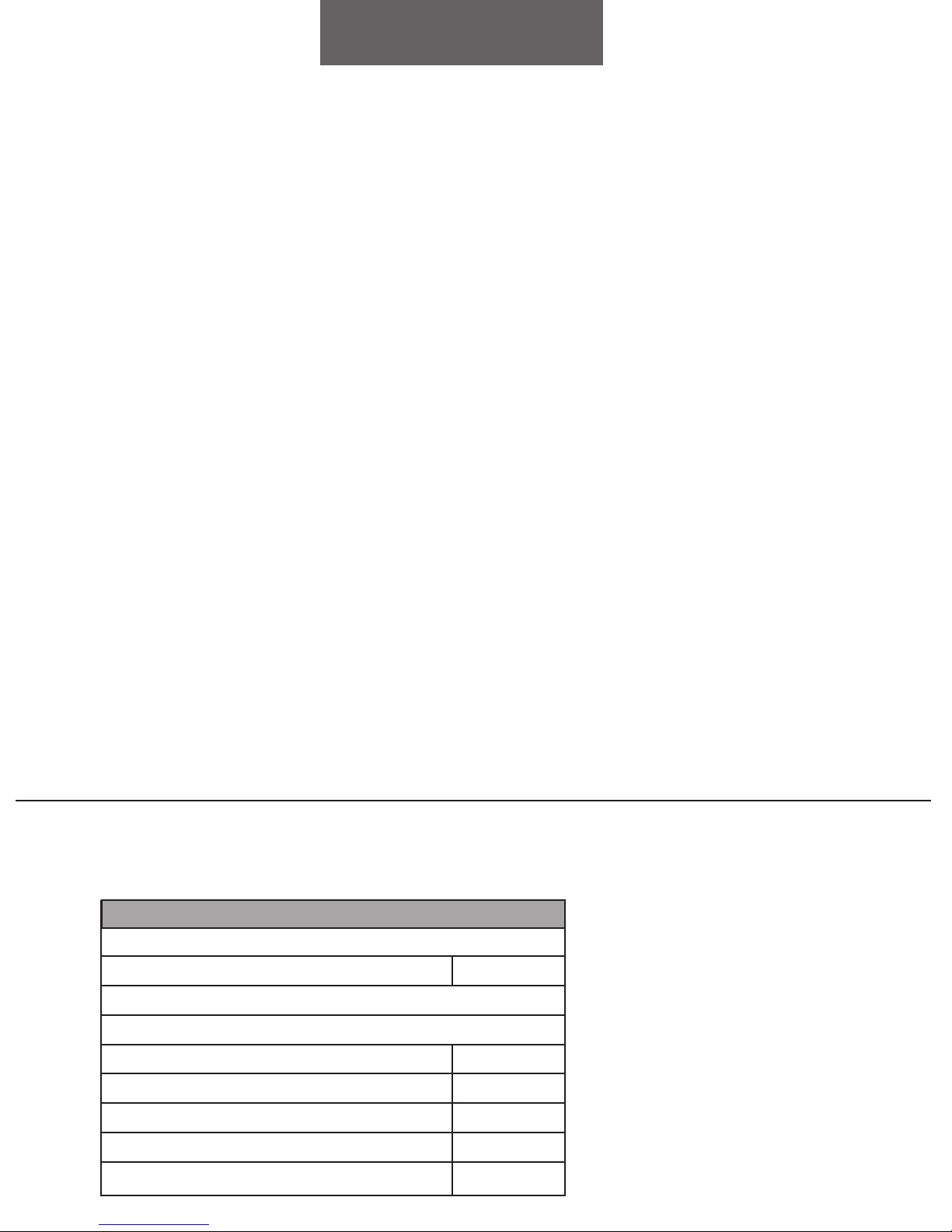

• Calculate the following figures before

installation:

1.Distance from the floor to the ceiling.

2.Distance between the floor to the coun-

tertop/stove (Usually 36 Inches).

3.Distance between the countertop/stove to the

range hood.

We recommend (25.5’ to 27 1/2’ Inches).

4. Height of hood and duct cover.

For the most efficient & quiet operation:

• It is recommended that the range hood be

vented vertically through the roof through 6”

(15.24 cm) or bigger round metal / aluminum

vent work.

• The size of the vent should be uniform.

• Use no more than two 90° elbows.

• Make sure there is a minimum of 24” (61 cm)

of straight vent between the elbows if more than

one elbow is used.

• DO NOT install two elbows together.

The length of vent system and number of

elbows should be kept to a minimum to pro- vide

efficient performance.

• The vent system must have a damper. If roof

or wall cap has a damper, DO NOT use damper

(if supplied) on top of the range hood.

• Use silver tape or duct tape to seal all joints in

the vent system.

• Use caulking to seal exterior wall or roof open-

ing around the cap.

10

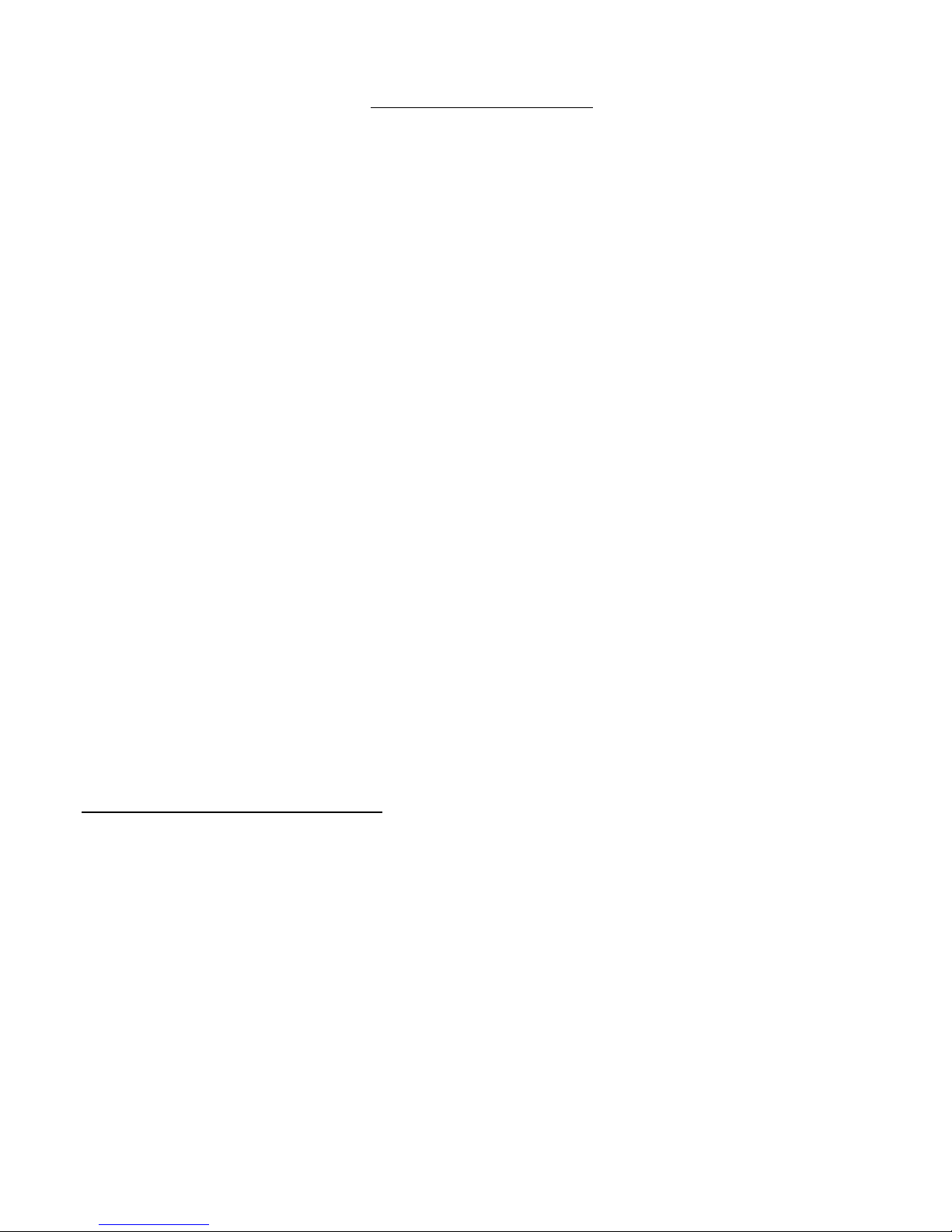

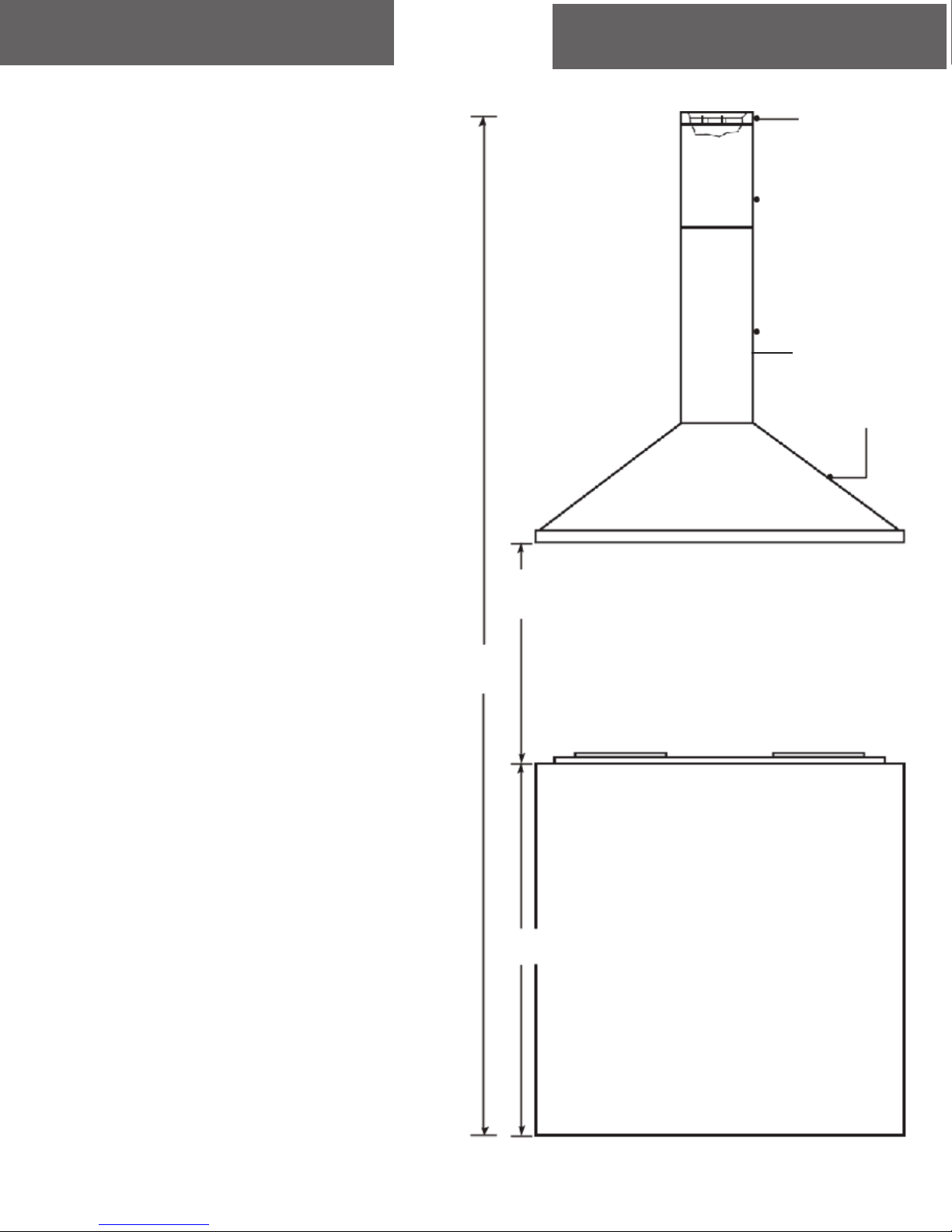

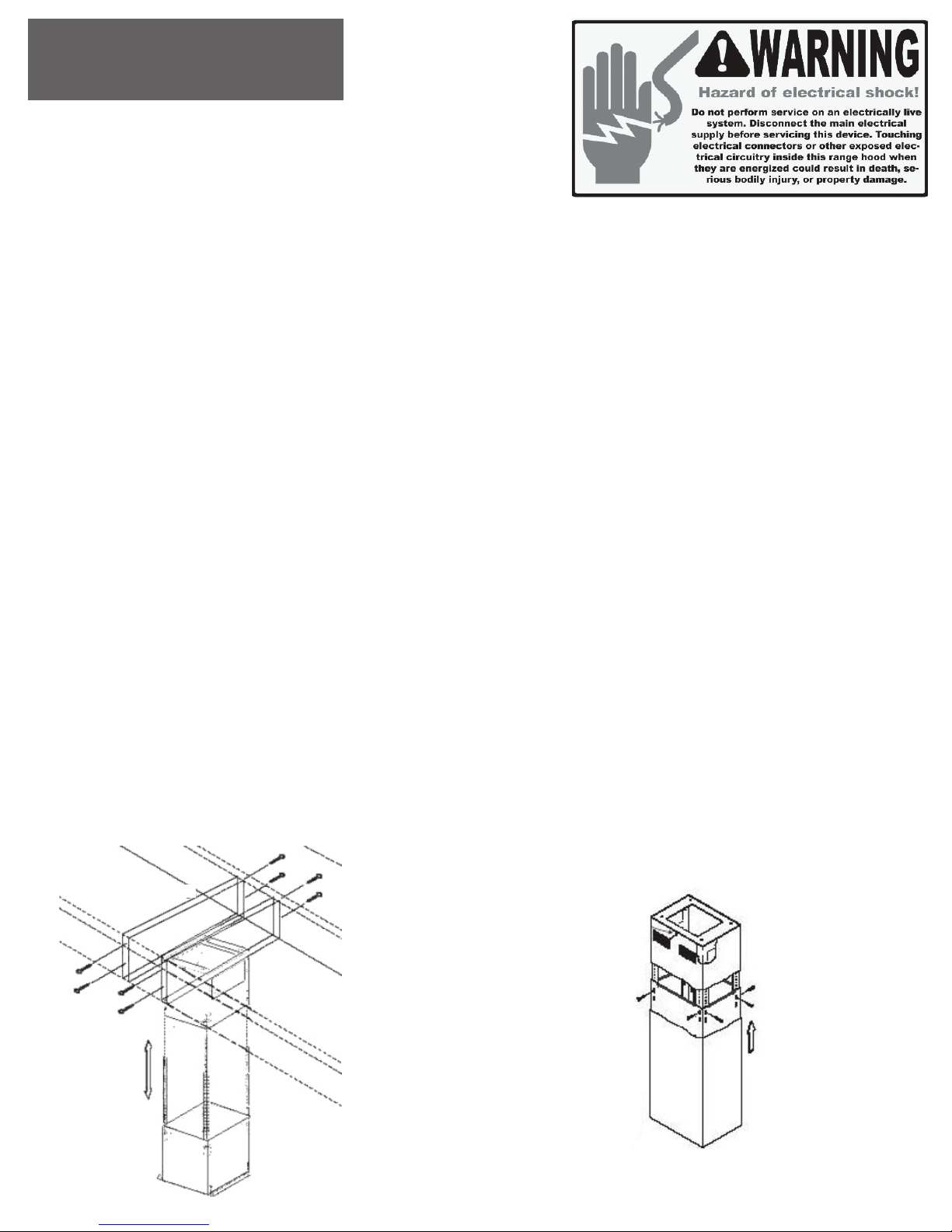

1. Align upper support frame with holes in the ceiling. Mount the

upper support frame to the ceiling using four “A” screws

(for sheet rock only). Make sure that the upper support frame

is securely fastened to the joint or support in the ceiling. Attach support frame to the ceiling using

ONLY the anchors recommended for your type of ceiling.

• Sheet rock ceiling: Attach support frame to ceiling joists or stud blockings if possible. If ceiling joists or

stud blockings are not available, it is required to build a supporting structure behind the sheet rock for

best weight support.

• Concrete ceiling: Use designated screws (not provided).

• Wood ceiling: Use at least 4” long wood screws (not provided).

2. Position the support frame extensions at the inside corners of the support frames, adjust and mark

each support frame extension as necessary to achieve the proper height for the range hood to be set

away from the cook top. (See Height and Clearance on Page 5 and Installation Overview on next page).

3. Fasten the support frame extension onto the lower support frame using four “B” bolts and “C” nuts as

shown in Figure 3. Repeat this step for rest of the support frame extensions. IMPORTANT: Always use

first and second holes on the support frame extensions.

4. Calculate the height of the duct tube and extend approximately 6 inches longer than required, connect

the upper end of the duct tube to the vent system.

5. Position the lower support frame with support frame extensions to the upper support frame, fasten

each extension with four “B” bolts and “C” nuts as shown in Figure 3.

7. Slide the upper chimney cover over the completed support frame and fasten with two “F” bolts to the

upper support frame. (See Figure 3 for illustrations).

8. Slide the lower chimney cover around the lower sup- port frame and around the upper chimney

cover. Have second person to hold it in position. (See Figure 4).

`

Adjust

support frame

extensions

Secure upper

support frame.

Slide up and secure

upper chimney.

Slide up, hold in position and

secure lower chimney

to range hood

Insert lower

support

frame with

extensions

Stud blockings

Figure 4

Figure 3