1. TECHNICAL DATA

Power (w) 1100

Max Head (m) 48

Max Flow Rate (l/min) 95

Outlet Size 1”

Caution

• Beforeputtingyourpumpunitintooperation,thoroughlyreadandfollowthese

instructions.

• Forsafetyreasons,thepumpingunitisnottobeusedbypeoplewhohavenot

previouslyreadtheinstructions.Itisnottobeusedbychildren.

• ThepumpunitisonlytobeinstalledinanelectricalsupplyconformingtoAustralian

ElectricalRegulations2002.Thismustincludealn=30mAsafetyswitch.Allelectrical

installationsaretobeperformedbyaLicensedElectrician.

• Thepumpunitistobeusedforcleanwaterwithtemperaturebelow35°.Thepump

mustnotbeallowedtofreeze.

• Donotraise,carryorxthepumpunitusingtheelectricalcable.

• Thepumpmustbedisconnectedfromthemainspowersupplybeforehandlingor

cleaningthepump.

• Ifthepowersupplycordhasbeendamaged,itmustbereplacedbythemanufacturer

oritsauthorisedcustomersupportserviceinordertoavoidallrisks.

• Thepumpisequippedwithathermaloverloadsafetydevice.Intheeventofany

overheatingofthemotor,thisdeviceautomaticallyswitchesoffthepump.Thecooling

timeisroughly15to20minutes,thenthepumpautomaticallycomesonagain.Ifthe

overloadcut-outistripped,itisessentialtoidentifyanddealwiththecauseofthe

overheating.SeeTroubleshooting.

• Thepumpmustnotbeusedtopumpsaltwater,sewage,ammable,corrosiveor

explosiveliquids(e.g.petroleumoil,petrol,andthinners),grease,oilsorfoodstuffs.

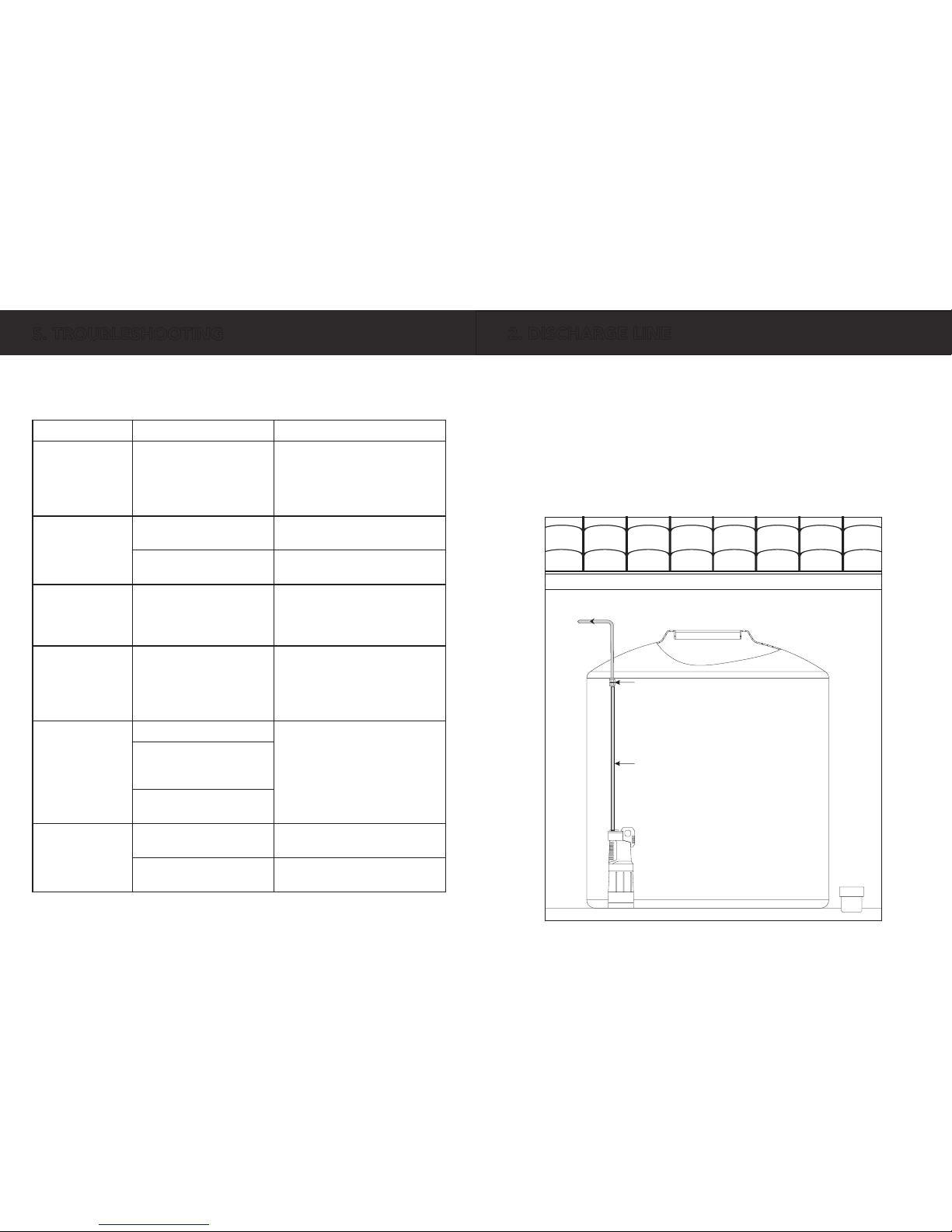

• Itisrecommendedthatpumpberaisedfromthebottomofthetanksothatwateris

notbeingdrawnfromverybottomwheresedimentcollectsandtoreducevibrations

fromthepumptransferringtothetank.

• Pumpmustbeinstalledinaneasilyaccessibleareaandwithplumbingttingsthat

makeremovalofpumpforservicingpossible.

Dear Customer, Congratulations on purchasing this high quality Leader

product. Please take a minute to read these installation and important

safety instructions before using your new equipment.

ClaytonEngineeringwarrantthisproductfor2yearsfromthedateofpurchase.

Thewarrantycoversmanufacturer’sdefectsinmaterialorworkmanship.Thewarranty

doesnotcovermalfunctionsduetomisuseorduetofailuretofollowtheinstructionsin

theinstructionmanual.AnyalterationstotheproductaretobeperformedbyaClayton

Engineeringapprovedserviceagent.Anyrepairsperformedbynonapprovedpersonnel

may void the warranty.

Tomakeaclaim,contactClaytonEngineering,26FrenchAve,Brendale,Q,4500on

provideproofofpurchaseandthenwillbeinstructedontheprocedureforrepairingor

replacementoftheproductunderwarranty.Allcostsincurredforrepairorreplace,and

additionalclaimscanbediscussedatthisstage.

Thiswarrantyisprovidedinadditiontootherrightsandremediesyouhaveunderlaw:

OurgoodscomewithguaranteesthatcannotbeexcludedundertheAustralian

ConsumerLaw.Youareentitledtoareplacementorrefundforamajorfailureandfor

compensationforanyotherreasonablyforeseeablelossordamage.Youarealsoentitled

tohavethegoodsrepairedorreplacedifthegoodsfailtobeofacceptablequalityand

thefailuredoesnotamounttoamajorfailure.

1st January 2012.

6. WARRANTY POLICY