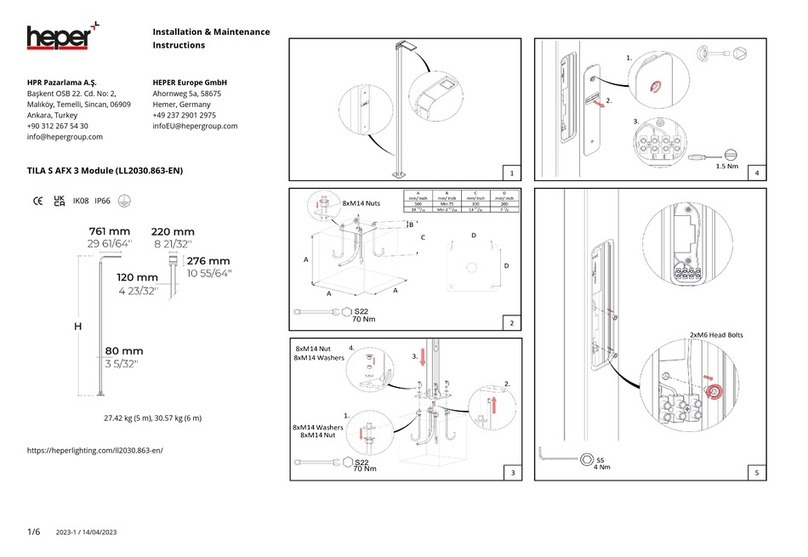

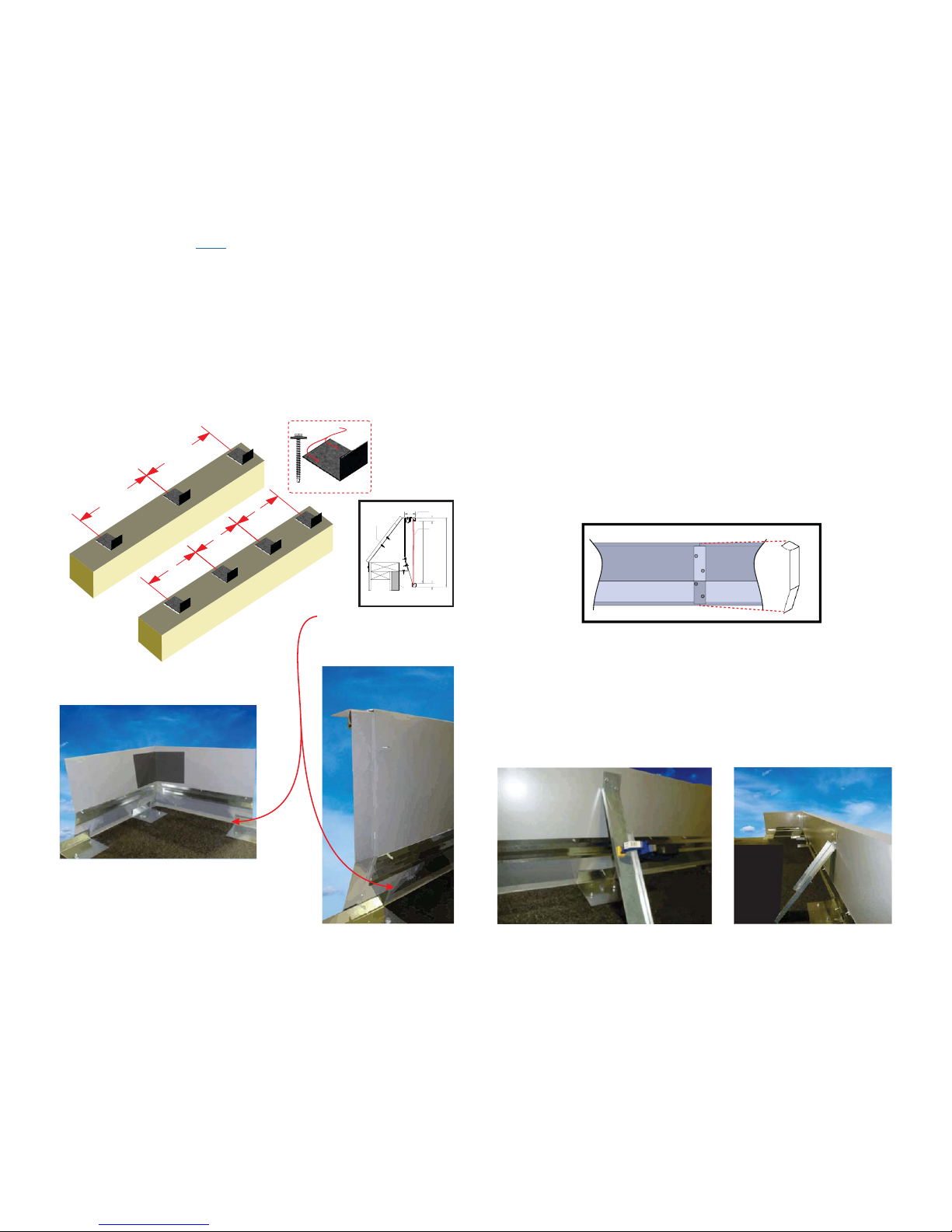

MOUNTING SURFACES VARY

PLEASE USE PROPER SCREW WHEN MOUNTING THE

HOUSING TO THE STRUCTURE

HEX HEAD TEK SCREW WITH NEOPRENE WASHER IS

PROVIDED AND NOT TO BE USED WITH MATERIAL OTHER

THAN METAL

GETTING STARTED CONTENTS

Following these few simple steps will ensure a successful installation each time.

Remember: No more than 32 boards per transformer.

1. Instructions, before starting Installation.READ ALL

2. Unpack your crate check the parts against the supplied parts list.

Report damaged parts or shortages immediately to preventNote:

job slowdown /stoppage to 1-800-634-4059 ext. 0.

3. Refer to attached provided print and con rm job measurements.

4. Layout your job on paper, making note of transformer

placement. Transformers can be placed in 3 con gurations.

If job measurements do not correspond to providedNote:

drawing, call Lektron immediately at 1-800-634-4059.

1

2

3

4

5

6

7

SEC. Page

Getting Started, Contents, and Installation Check list

1. Component Identi cation & Required Tools.............................................................................

2. Proper Measuring & Placement Of The Lightband.................................................................

3. Installation of Cut Section & Sizing the LED.............................................................................

4. Setting the Transformer............................................................................. ......................................

5. Testing Each Section..........................................................................................................................

6. Lens Installation..................................................................................................................................

7. End Cap Installation..........................................................................................................................

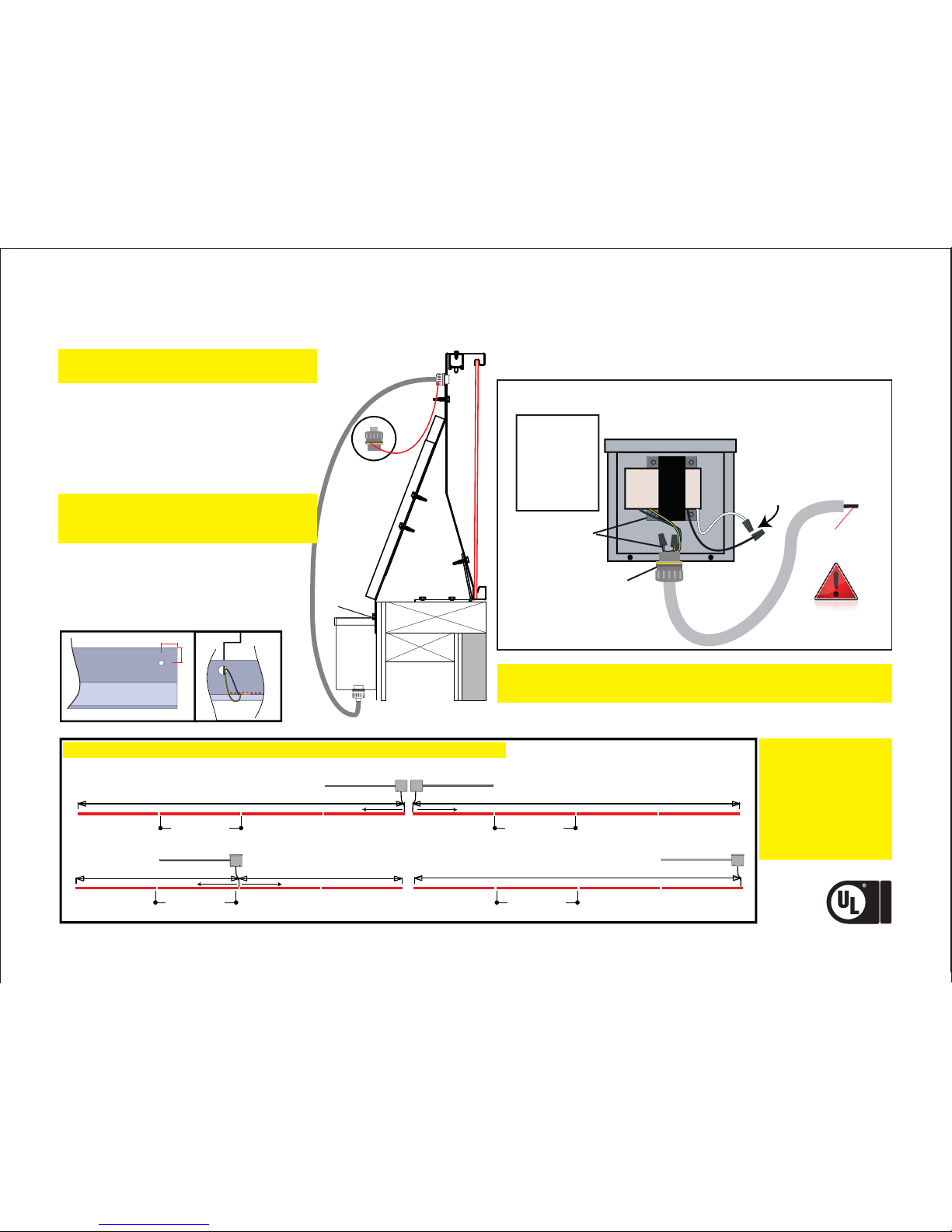

LED SPECIFICATIONS

ELECTRICAL

CERTIFIED

SAFETY US CA

Output

Input

Power Rating

Maximum Load

(In a Single Direction)

Current at Max. Load

25 VAC

120 VAC

100 VA

32 12" Boards 20L

.55A

=

12" LED boards pull close to the same voltage as shorter

break-apart boards. Maximum of 3 - 3" Boards per circuit.

No more than 32 boards on a circuit. Do not connect more

than one transformer per circuit.

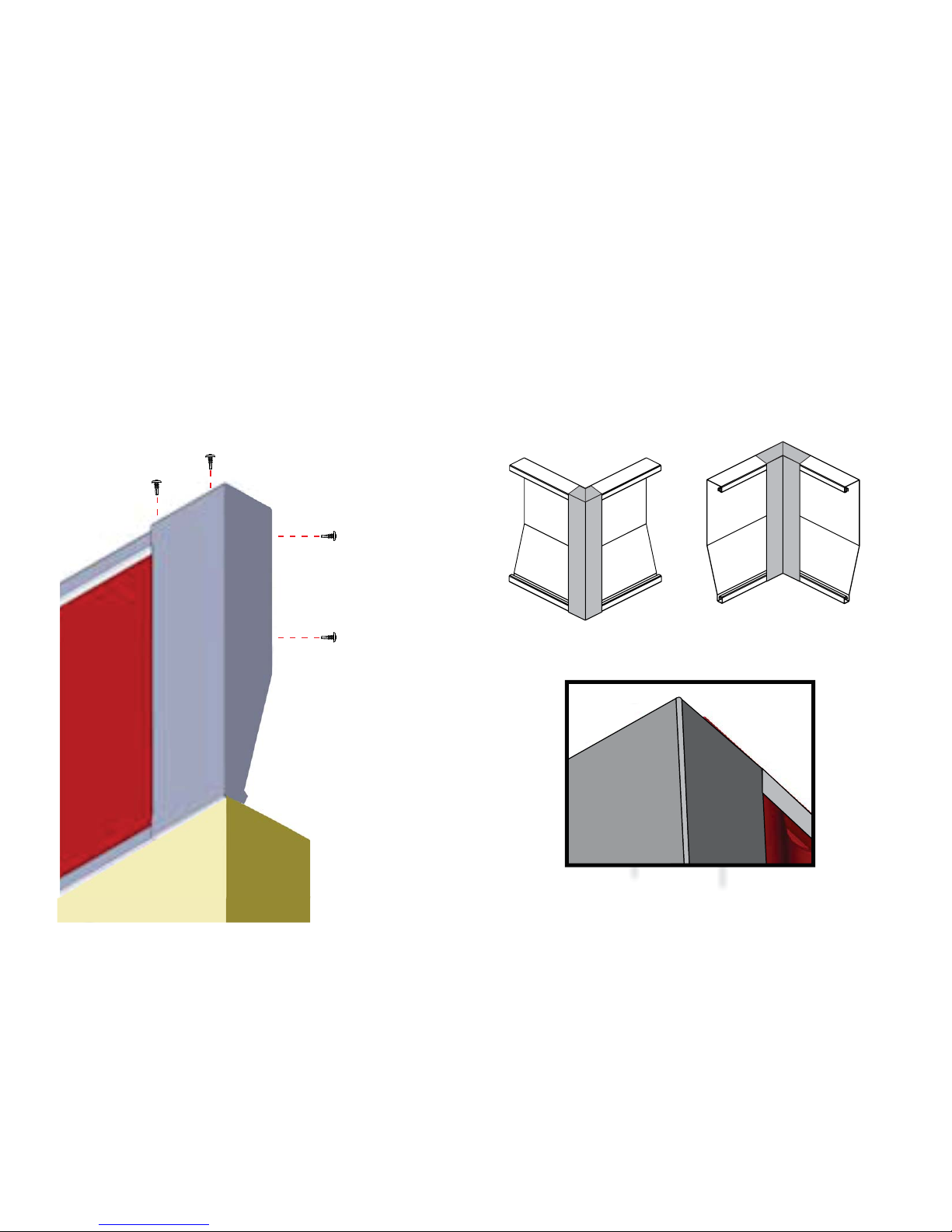

INSTALLATION SEQUENCE

Belowwehaveidenti edasequenceofoperationsthatwillguideyouinthe

proper installation of the parapet band system. However, always be aware of

your surroundings and site conditions that cannot be taken into consideration

when writing this guideline. It is always your responsibility to ensure a safe and

clean workplace environment. if they are different from what was1. Review the onsite construction plans;

supplied withthe parapet band system or if you are missing anycomponents in

the system call Lektron LED Technologies at 1-800-634-4059 immediately.

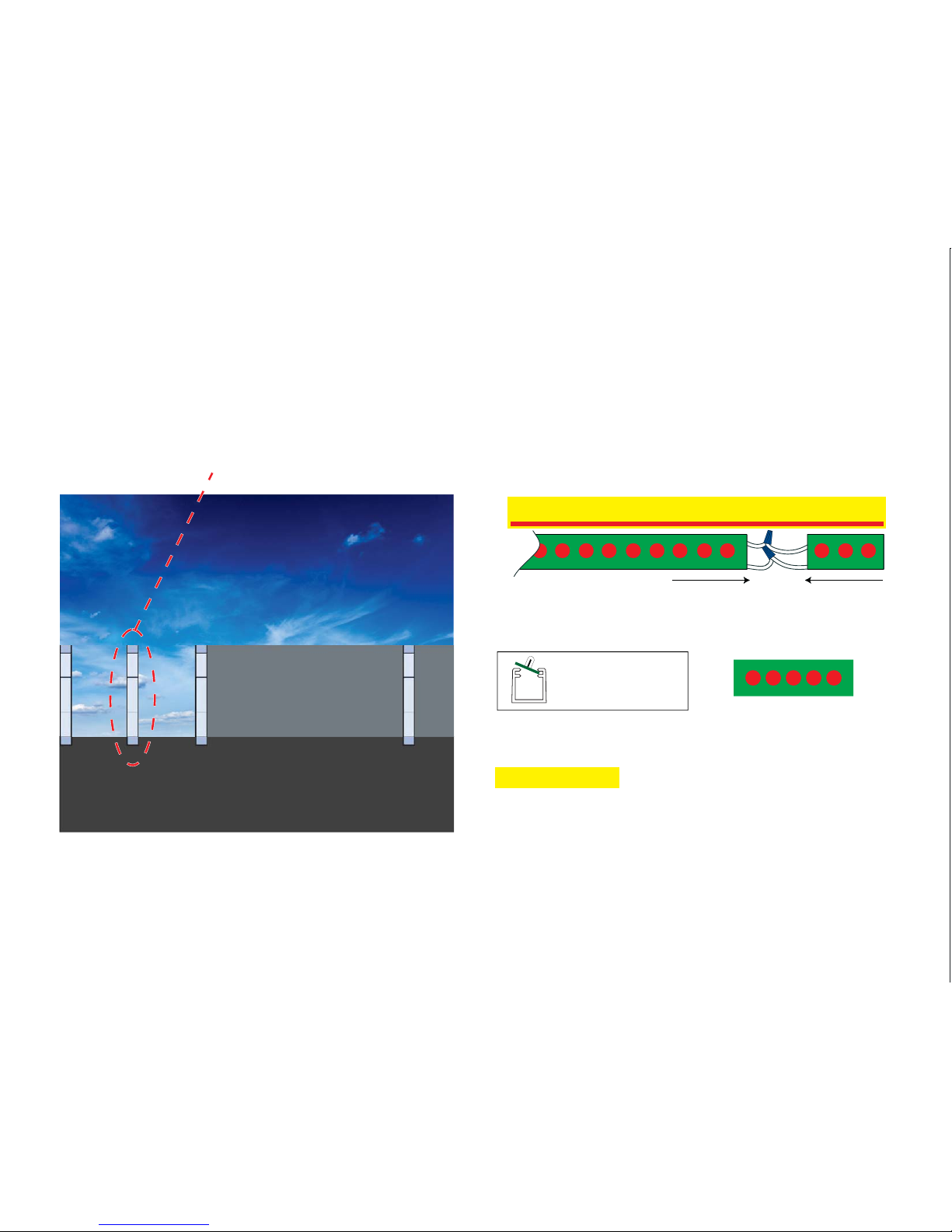

It is recommended that you start your installationwith a corner, and then

work to the towers or the back of building. This will allow the smaller section

of cut housing to be on the end opposite of the corners. By doing this it will

eliminate two small sections of housing being close to one another.

reference “Installing the Mounting Brackets” for2. Install mounting brackets;

proper installation procedures.

3. Install string line it is recommended that you install aor laser level;

string line 151/4”up from the top of the parapet wall to properly align the

top of the housing and corners.

4. Set corners into place; reference “Installing the Inside and Outside Corners”

for proper installation procedures.

reference “Installing the Housings” for proper5. Set housing into place;

installation procedures. reference “Installing Adjustment6. Install remaining adjustment brackets;

Brackets” for proper installation procedures.

reference “Installing LED's” for proper installation procedures.7. Install LED's;

8. Install the transformers;it is critical to test the LED's for proper operation

prior to installing the lens.

9. Install the lens; reference “Installing the Lens” for proper insta llation

procedures.

10. Install the end and corner caps; reference “Installing the End Caps” and

“Installing the Inside and Outside Corners” for proper installation procedures.

11. Inspect to insure parapet band system looks and operates correctly.