.

~:""

.

II

I.

INSTRUCTIONS

(Continued)

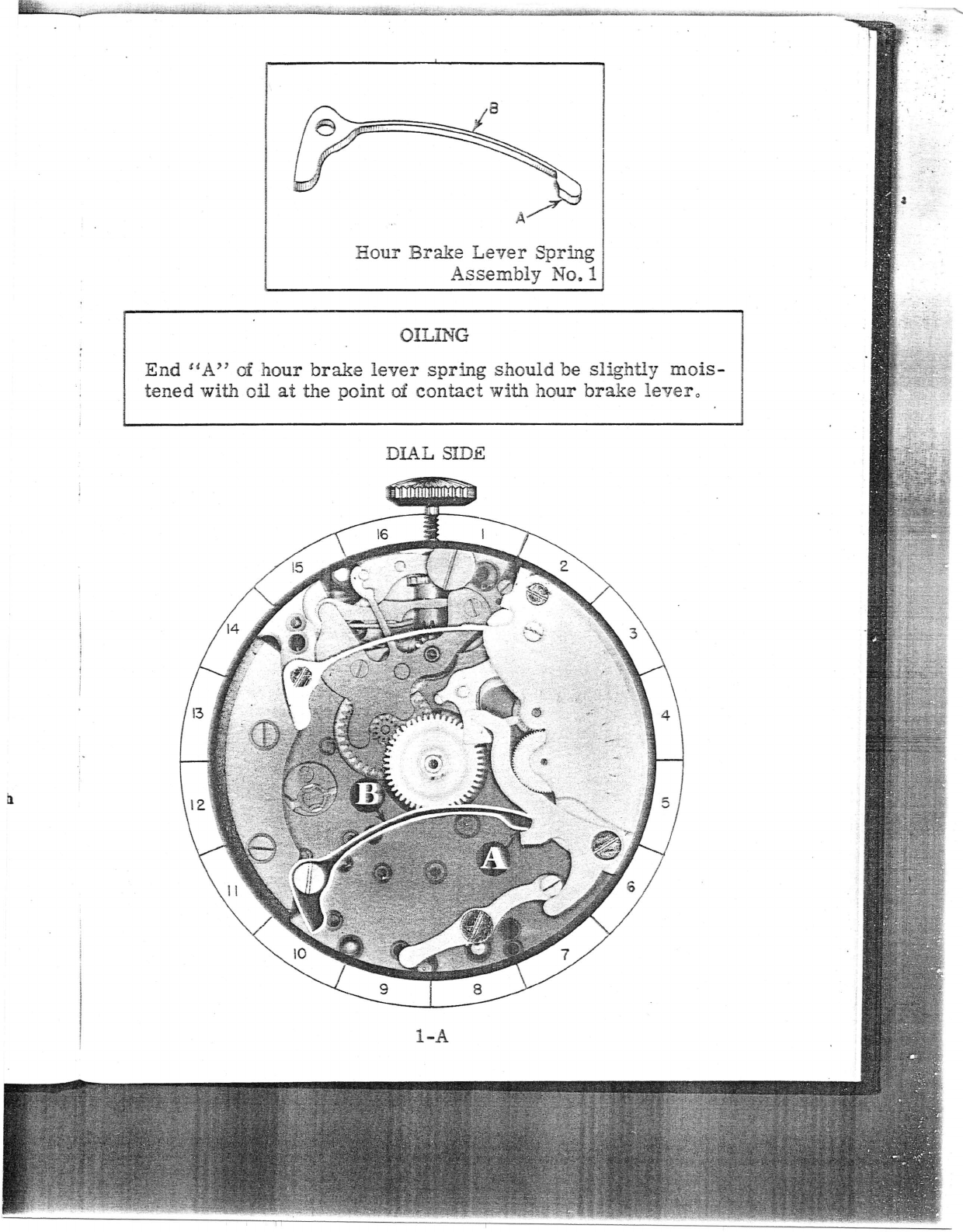

10. Replace the part in its exact location as shown in photograph, using the procedure

as described in the text.

11. After you find the correct location for this part in the watch, read the oiling

procedure for this part. The oiling procedure for this part is located underneath

the isometric drawing. It is best to read the oiling procedure before you put each

part in place as there are certain parts that must be oiled immediately as it may

prove difficult to oil them later.

..

-.

~

..

12. Replace the screw that holds this part in place. Of course, the screws should

be kept in order as we advised above, but if the screws are not in order or the watch

was received with screws mixed up, you will find a screw drawn for each part that

requires a screw at the bottom of the text page.

13. After replacing this part, replace the next part, etc., until the last part is

replaced, which will be part No.1. Each part should be replaced using the same

procedure as described in the text.

(Naturally, the assembly of the chronograph is exactly the reverse of the disassembly)

14. After disassembling and assembling the chronograph mechanism, start on page

1 and read the function of this part. After reading the function of this part, continue

to read the function of each part throughout the book. Study each part, one at a

time. This text should help you to understand more fully the purpose of each part

in the chronograph mechanism.

15. Now put movement in its case with dial on, then replace hands.

,0

I.

16. Study the text on functional results in this book, and check the chronograph

mechanism as described in this text.

NOMENCLATURE OF PARTS FOR CHRONOGRAPH MECHANISM

17. After you have become familiar with the Chronograph mechanism, you can

disassemble and assemble the chronograph by using the nomenclature of parts as a

.guide. This makes it possible for you to use a procedure without going through each

page in the book.

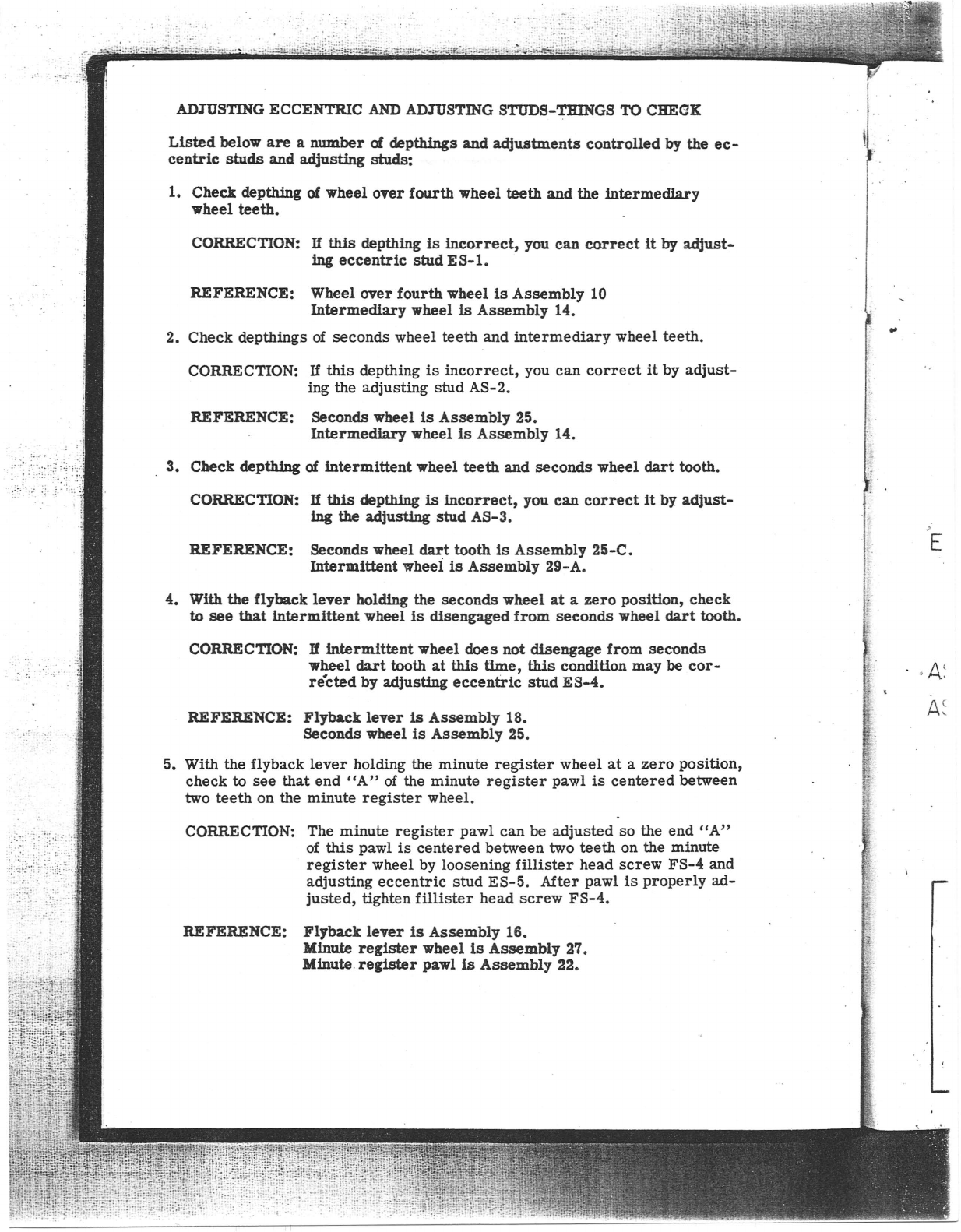

18. ADJUSTMENTOF ECCENTRICSTUDS:

Read the text on adjustment of eccentric studs, this text should be read in reference

to the eccentric stud picture. Now adjust each eccentric stud one at a time in the

watch, as described in the text. Use the picture to show you the position of these

studs.

19. On each page in this book the part number and the page number are the same.

This makes it convenient for the reader and eliminates any confusion.

I~.