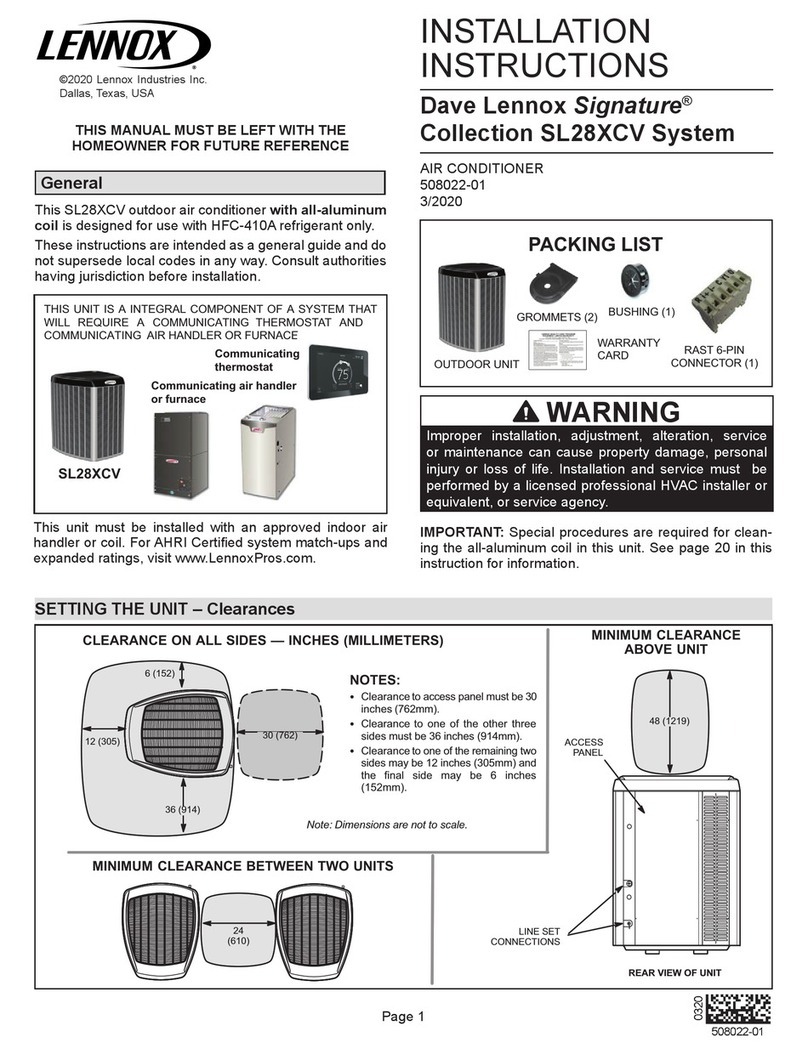

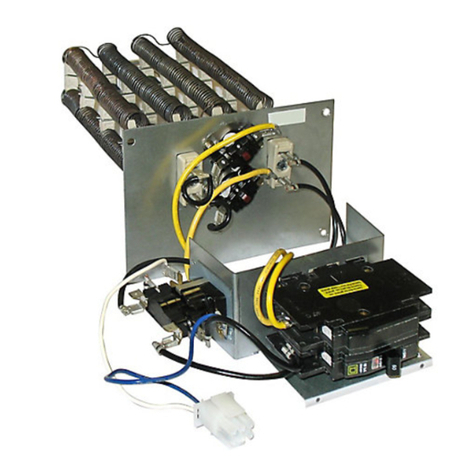

Isolate Gas Valve To Pressure Test

Manual Main Shut-off Valve Will Not Hold Test

Pressures in Excess of 0.5 PSIG (14 in. w.c.)

unit

gas valve cap

Fiaure 6

NOTE -Codes may require that manual main shut off valve

and union (furnished by installer) be installed in gas line exter-

nal to unit. Union must be of the ground joint type.

,WARNING

After gas piping is complete, carefully check all piping con-

nections (factory and field) for gas leaks, Use soap solution

or other preferred means.

NOTE -In case of emergency shutdown, shut off main

manual gas valve and disconnect main power to unit.

These devices should be properly labeled by installer.

The heating value of the gas may differ with locality, The

value should be checked with the local gas utility.

NQ TE -Units are shipped equipped for natural gas, but can

be converted to LPG/propane with a conversion kit.

NOTE- There may be a local gas utility requirement speci-

fying a minimum diameter for gas piping. All units require a

1/2 inch pipe connection at the gas valve.

Gas piping recommendations:

1 - A drip leg and a ground joint union must be installed in

the gas piping.

A ground joint union is recommended by the man-

ifold/valve,

2 - When required by local codes, a manual shut-off valve

may have to be installed outside of the unit,

3 - Use pipe thread sealing compound resistant to pro-

pane gas sparingly on male threads,

4 - The gas supply should be a separate line and installed

in accordance with all safety codes. After the gas con-

nections have been completed, open the main shut-off

valve admitting normal gas pressure to the mains,

Check all joints for leaks with soap solution or other

material suitable for the purpose,

Ak CAUTION

5 - The furnace and its individual manual shut-off valve

must be disconnected from the gas supply piping sys-

tem during any pressure testing of that system at test

pressures in excess of 1/2 PSIG (3,48kPa),

AkIMPORTANT

6 - A 1/8 inch N.ET. plugged tapping, accessible for test

gage connections, must be installed immediately up-

stream of the gas supply connection to the furnace,

Check the unit rating plate for type of gas that unit is

equipped for. If conversion is required use the approved

conversion kit, The unit may be converted in the field for

use with LPG/propane gas with accessory kit by an

approved licensed pipe fitter or technician,

All LPG/propane gas equipment must conform to the safety

standards of the National Fire Protection Association.

For satisfactory operation, LPG/propane gas pressure must

be a minimum of 11 inches W.C, at the unit under full load,

Complete information regarding tank sizing for

vaporization, recommended regulator settings, and pipe

sizing is available from most regulator manufacturers and

LPG/propane gas suppliers,

Check all connection for leaks when piping is completed,

using a soapy solution,

ALL WIRING SHOULD BE DONE IN ACCORDANCE

WITH NATIONAL ELECTRIC CODE, ANSI/NFPA No. 70

(LATEST EDITION), IN CANADA CSA C22.2 Part 1

(LATEST EDITION), OR WITH LOCAL CODES, WHERE

THEY PREVAIL.

Page 8