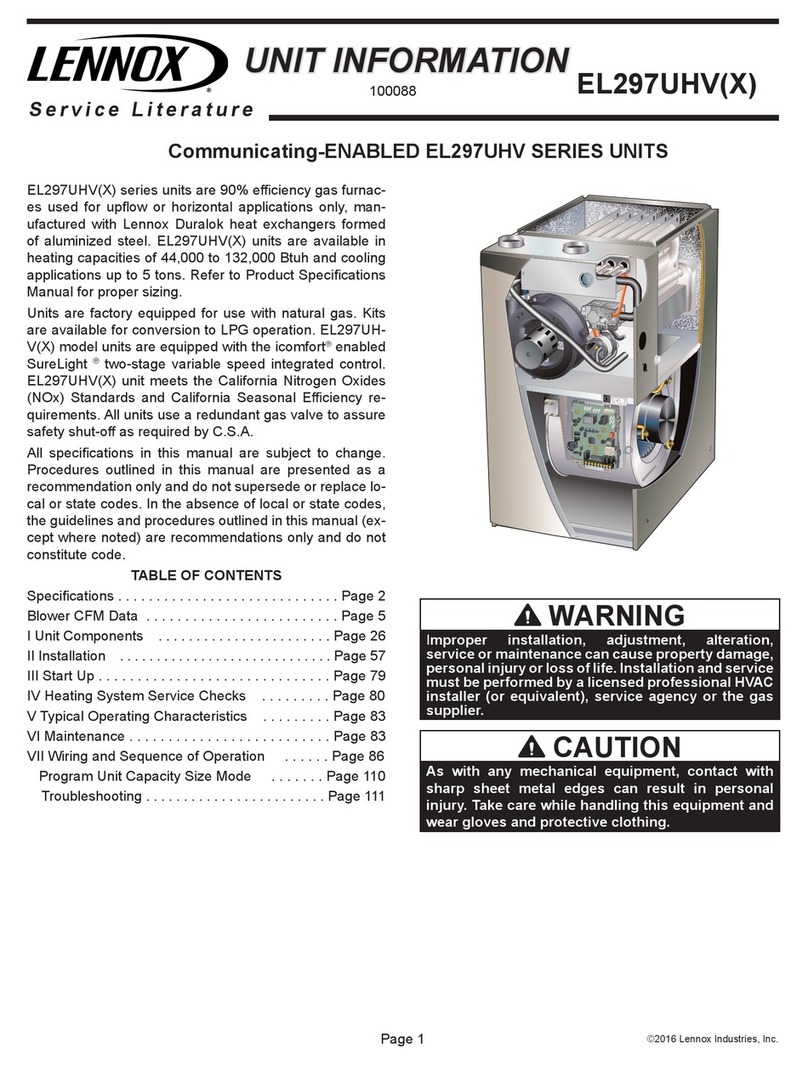

Page 3

WARNING

Do not use this furn ce if ny p rt h s been underĆ

w ter. A flood-d m ged furn ce is extremely d nĆ

gerous. Attempts to use the furn ce c n result in

fire or explosion. Immedi tely c ll qu lified serĆ

vice technici n to inspect the furn ce nd to repl ce

ll g s controls, control system p rts, nd electric l

p rts th t h ve been wet or to repl ce the furn ce,

if deemed necess ry.

IMPORTANT

Any dditions, ch nges, or conversions required in

order for the ppli nce to s tisf ctorily meet the pĆ

plic tion needs must be m de by Lennox service

technici n using f ctory specified nd pproved

p rts.

WARNING

Improper inst ll tion, djustment, lter tion, service

or m inten nce c n c use property d m ge, personĆ

l injury or loss of life. Inst ll tion nd service must

be performed by qu lified inst ller, service gency

or the g s supplier.

S fety Instructions

1 - Keep the furnace area clear and free of combustible

material, gasoline, and other flammable vapors and

liquids. If it is installed in an insulated area, the furnace

must be kept free of insulating material. Insulating maĆ

terial may be combustible.

2 - DO NOT obstruct air flow to unit. Unit must receive an

unobstructed flow of combustion and ventilating air.

DO NOT block or obstruct air openings on the furnace

or air openings to the area in which the furnace is

installed. Take care to maintain established clearĆ

ances surrounding the furnace.

3 - DO NOT store chlorine or fluorine products near unit

or introduce these products into the combustion air.

These products can cause furnace corrosion.

4 - DO NOT dr w return ir from room where this furĆ

n ce, or ny other g s ppli nce (ie., w ter he tĆ

er), is inst lled. When return air is drawn from a room,

a negative pressure is created in the room. If a gas apĆ

pliance is operating in a room with negative pressure,

the flue products can be pulled back down the vent

pipe and into the room. This reverse flow of the flue

gas may result in incomplete combustion and the

formation of carbon monoxide gas. This toxic gas

might then be distributed throughout the house by the

furnace duct system.

WARNING

The blower door must be securely in pl ce when the

blower nd burners re oper ting. G s fumes, which

could cont in c rbon monoxide, c n be dr wn into

the living sp ce resulting in person l injury or de th.

Your furn ce is g s ppli nce. It is critical that the gas

supplied to the unit be completely burned to avoid the proĆ

duction of carbon monoxide gas. Complete combustion of

the gas requires, but is not limited to, correct gas pressure

and gas flow rate, adequate combustion, air, and proper

venting.

WARNING

C rbon monoxide g s is invisible, odorless nd

toxic.

Exposure to carbon monoxide gas can cause personal injuĆ

ry and even death to all occupants, including pets. ny item

that is powered by or gives off heat from a combustion proĆ

cess (including lawn mowers, automobiles, and fireplaces)

has the potential to produce carbon monoxide gas. Because

of this, Lennox recommends the use of c rbon monoxĆ

ide detector in your home, even if you do not own g s

ppli nces. Reliable detectors are available at reasonable

retail prices. Contact your Lennox dealer for more details

about this investment in your safety.

Your furnace is designed to meet standards set by nationĆ

al agencies, and to operate safely when properly installed

and maintained. However, the unit's performance can be

greatly impacted by the individual installation and the opĆ

erating environment. It is your responsibility to ensure that

this appliance is maintained. Proper maintenance is critiĆ

cal for your safety and the satisfactory operation of the

product. Lennox strongly recommends nnu l inĆ

spection nd m inten nce of this ppli nce. Contact

your Lennox dealer for an inspection by a qualified service

technician.

Lighting Inform tion & Oper tion

WARNING

If you do not follow these instructions ex ctly, fire

or explosion m y result c using property d m ge,

person l injury or de th.

BEFORE LIGHTING smell all around the appliance area

for gas. Be sure to smell next to the floor because some gas

is heavier than air and will settle on the floor.