Lennox GCS16−024 Guide

Other Lennox Furnace manuals

Lennox

Lennox G32Q4-100 User manual

Lennox

Lennox ELO183UF68P36 User manual

Lennox

Lennox SIGNATURE SLP99UH070XV36B User manual

Lennox

Lennox 78RGF Series Setup guide

Lennox

Lennox EL297UH045XV36B Installation and operation manual

Lennox

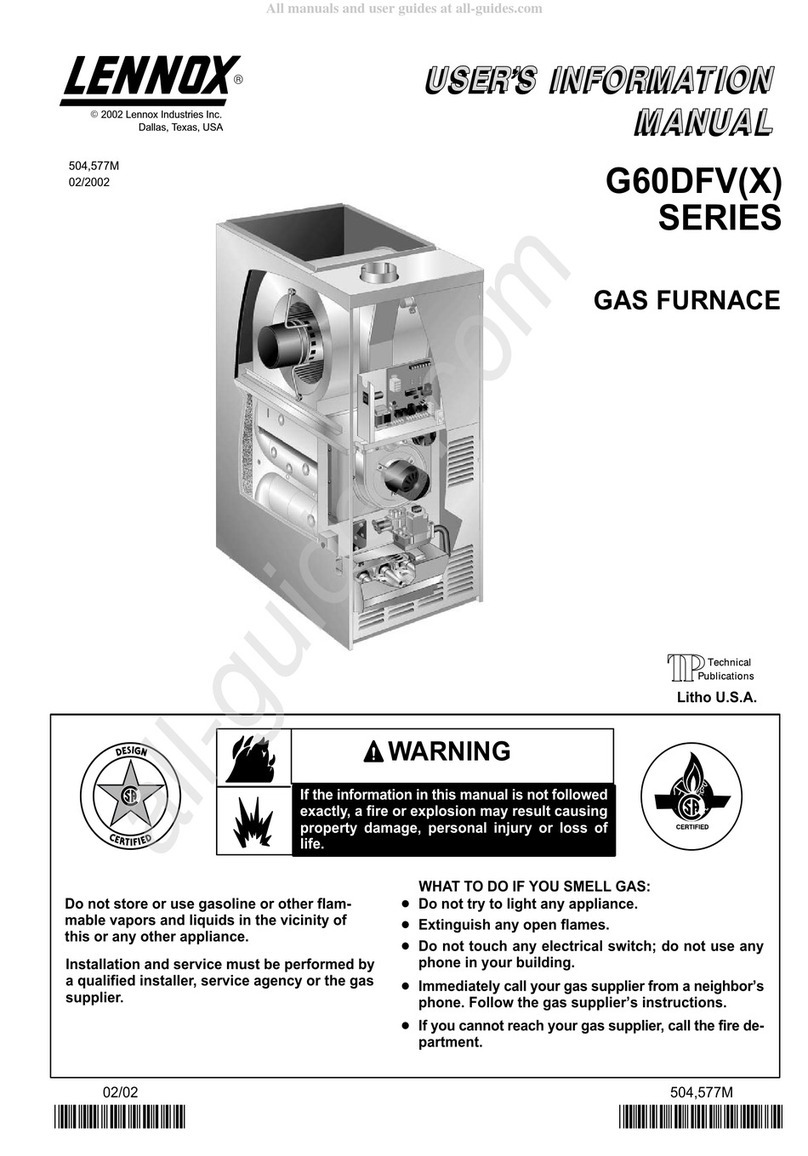

Lennox G60DFV Series Guide

Lennox

Lennox O23 Installation and operation manual

Lennox

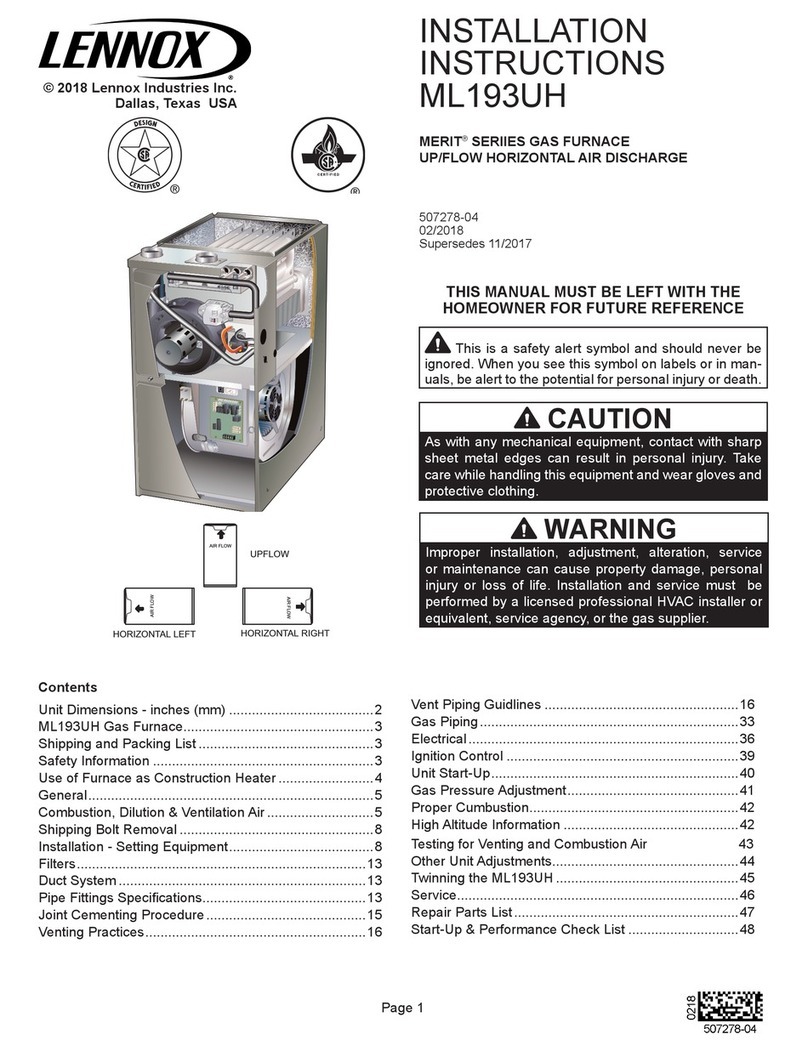

Lennox ML193UH User manual

Lennox

Lennox G60DFV Series User manual

Lennox

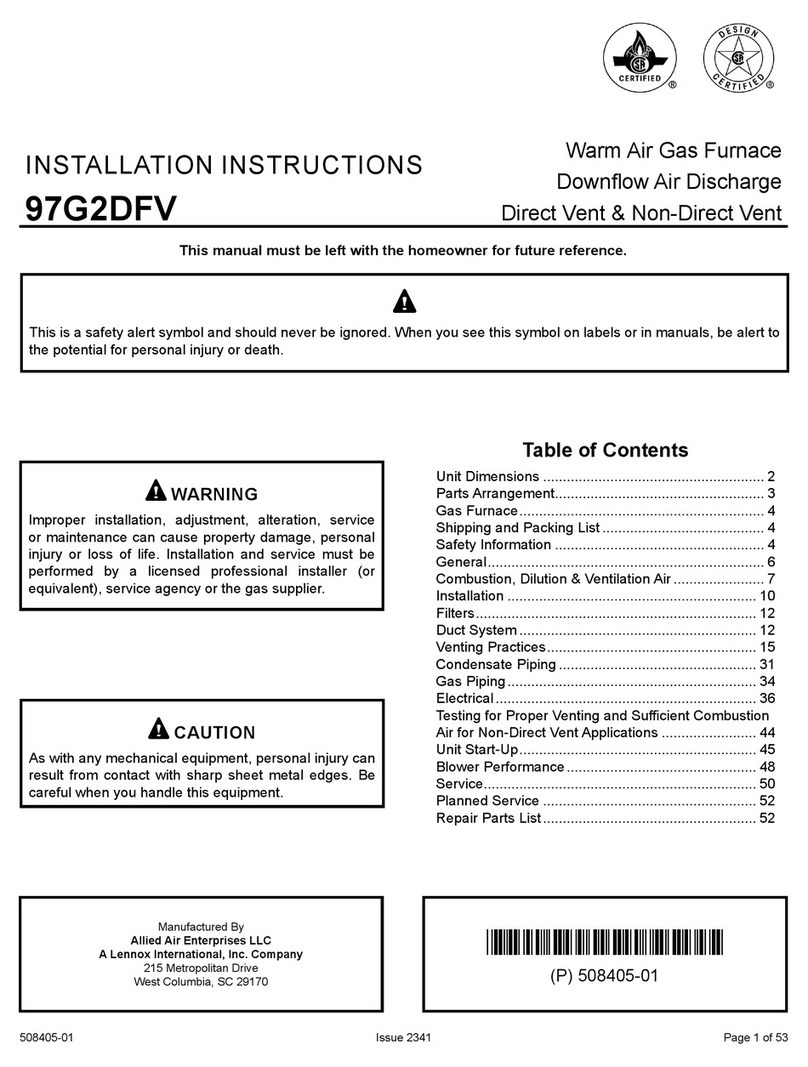

Lennox 97G2DFV User manual

Lennox

Lennox SLO183BF101/114V42 User manual

Lennox

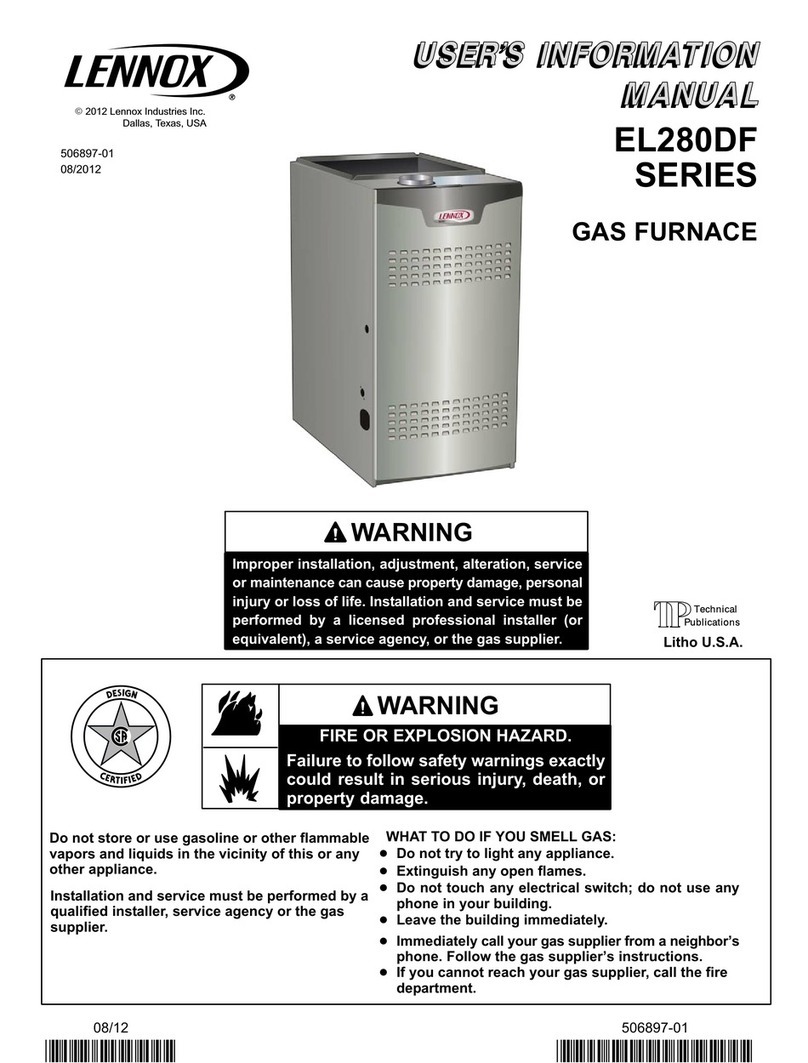

Lennox EL280DF SERIES Guide

Lennox

Lennox 80G1DF User manual

Lennox

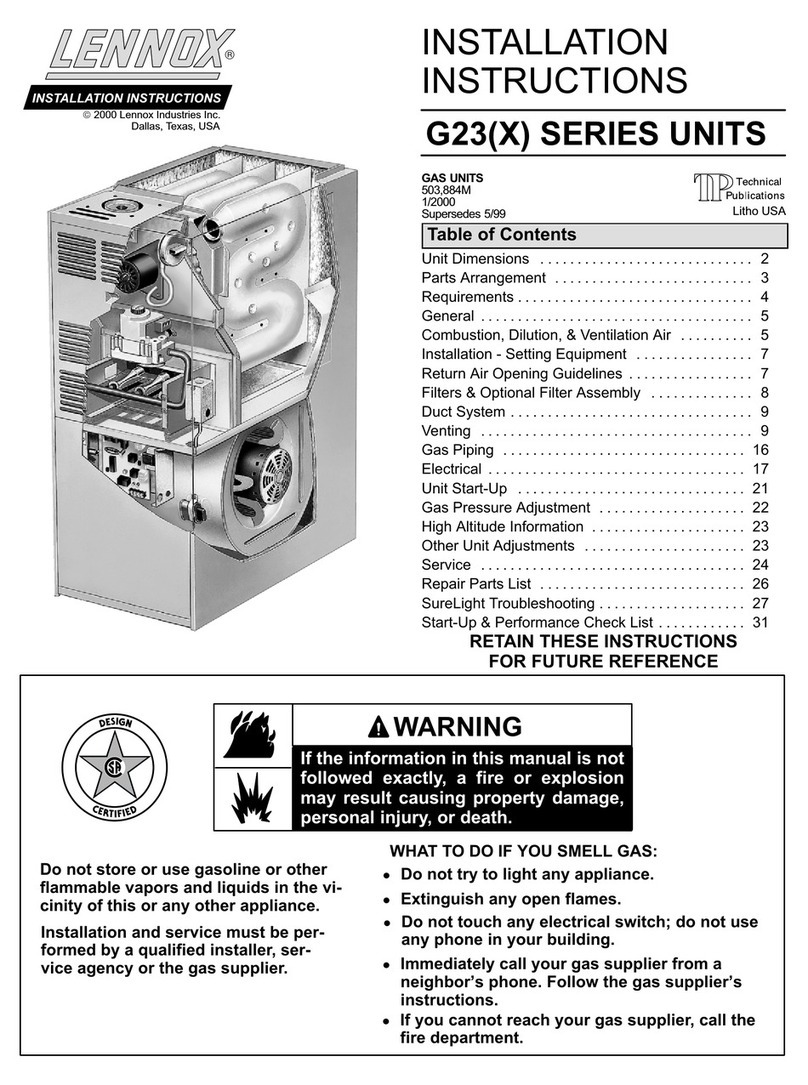

Lennox G23 Series User manual

Lennox

Lennox ELITE EL296DFE User manual

Lennox

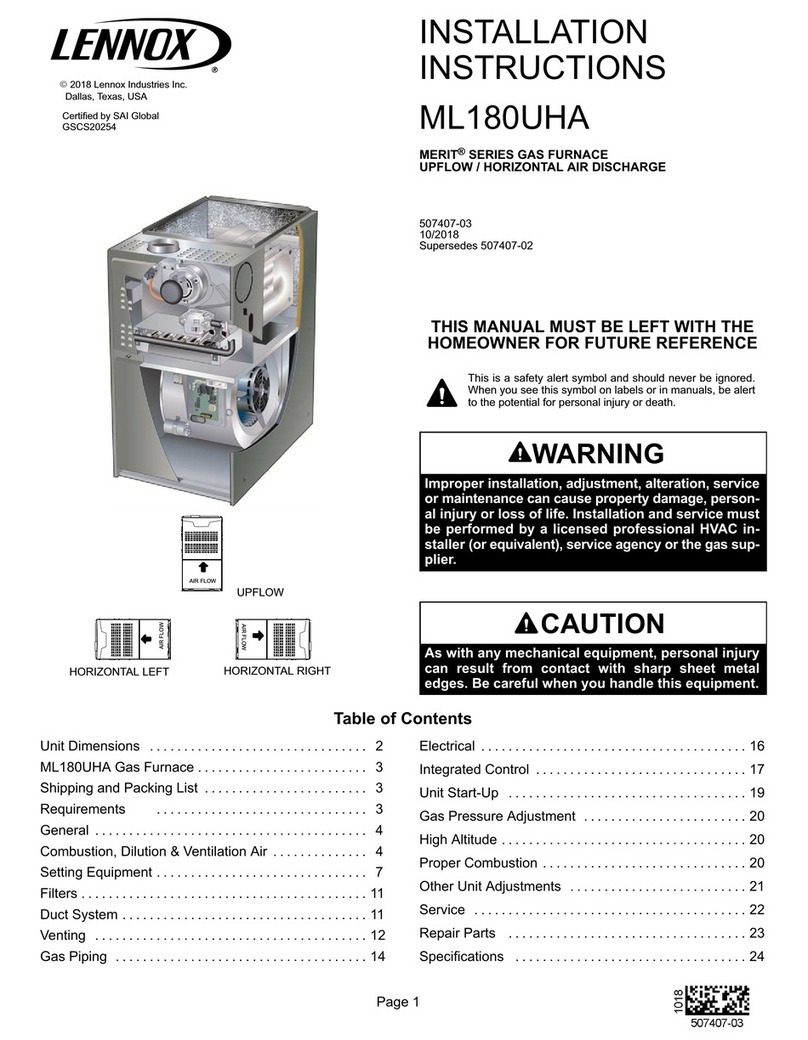

Lennox ML180UH SERIES User manual

Lennox

Lennox EL180DFE Series User manual

Lennox

Lennox ML195DF MERIT SERIES Guide

Lennox

Lennox G40UH Series User manual

Lennox

Lennox SLP98DFV SERIES Guide

Popular Furnace manuals by other brands

Armstrong

Armstrong EG7H SERIES Installation and maintenance instructions

Payne

Payne PG92ESA Installation, start-up, operating and service and maintenance instructions

SUPREME

SUPREME FEM10-M2301CM-A Installation instructions and homeowner's manual

Ingersoll-Rand

Ingersoll-Rand S9V2B080D4VSAC/D Installer's guide

Johnson Controls

Johnson Controls TM9T User's information manual

Fluke

Fluke 9118A user manual

Intertherm

Intertherm M7RL Series user manual

HDG

HDG Pelletmaster 15 Operation manual

Pinnacle

Pinnacle Aero Bella AB-716C-QH User's manual and operating instructions

Nortek

Nortek MG2S Series installation instructions

VERDER

VERDER CARBOLITE GERO ABF 8/28 Installation, operation and maintenance instructions

Goodman

Goodman GMV9 Installation & operating instructions

SUPREME

SUPREME SUP10-M2301C Installation instructions and homeowner's manual

Dettson

Dettson AMT400B34-SM1PMA Installation instructions and homeowner's manual

Evcon

Evcon DGD 60 MBH installation instructions

Trane

Trane S8B1A026M2PSAB Installer's guide

Hart Sceintific

Hart Sceintific 9113 user manual

Whirlpool

Whirlpool Gold WGGE45 installation instructions