Lennox SLP98DFV SERIES User manual

Other Lennox Furnace manuals

Lennox

Lennox ML193DF User manual

Lennox

Lennox G27M Series Guide

Lennox

Lennox G17Q2-50 Installation and operation manual

Lennox

Lennox SLP98UHV SERIES User manual

Lennox

Lennox EL180UHE SERIES User manual

Lennox

Lennox SL280DFV Installation and operation manual

Lennox

Lennox Elite series User manual

Lennox

Lennox G41UF Series Guide

Lennox

Lennox SL280UHNX Series Installation and operation manual

Lennox

Lennox SLP99UHV Series Installation and operation manual

Lennox

Lennox EL195UHE Elite Series Guide

Lennox

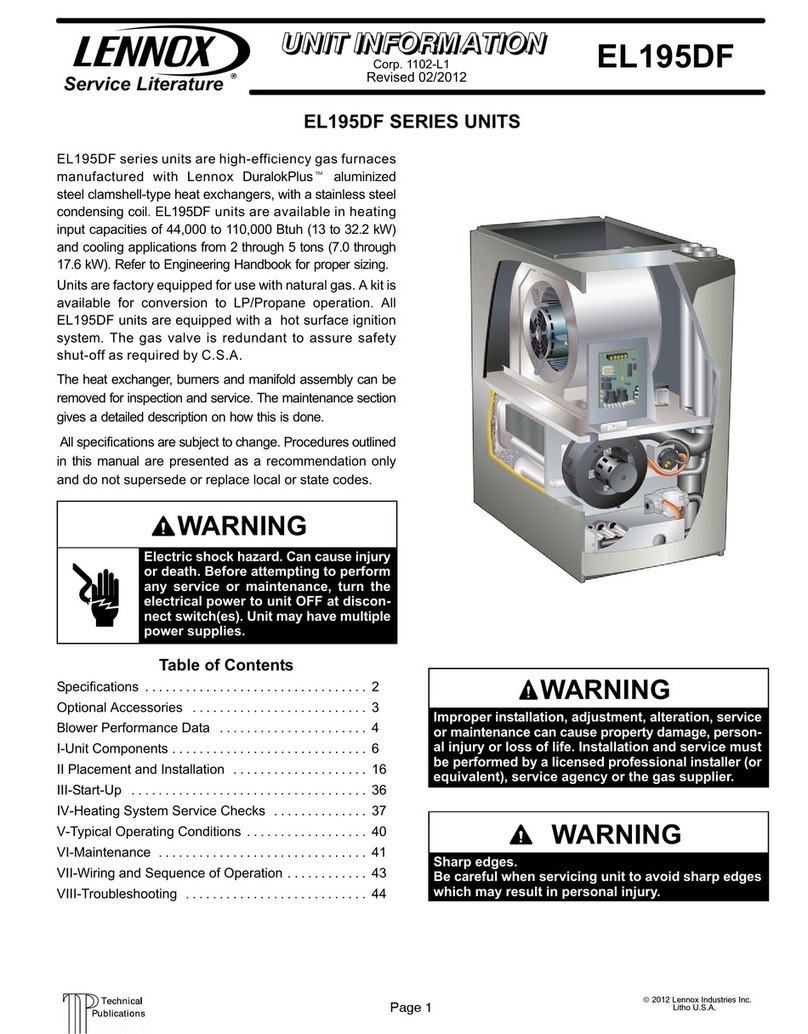

Lennox EL195DF SERIES User manual

Lennox

Lennox EL195UH040NE36B User manual

Lennox

Lennox EL296UHE User manual

Lennox

Lennox GHR32 Series Guide

Lennox

Lennox EL196DFE Series Guide

Lennox

Lennox GSR14 User manual

Lennox

Lennox Allied Air 96G2UHV User manual

Lennox

Lennox ML195UH Guide

Lennox

Lennox EL196UHE User manual

Popular Furnace manuals by other brands

Armstrong

Armstrong EG7H SERIES Installation and maintenance instructions

Payne

Payne PG92ESA Installation, start-up, operating and service and maintenance instructions

SUPREME

SUPREME FEM10-M2301CM-A Installation instructions and homeowner's manual

Ingersoll-Rand

Ingersoll-Rand S9V2B080D4VSAC/D Installer's guide

Johnson Controls

Johnson Controls TM9T User's information manual

Fluke

Fluke 9118A user manual

Intertherm

Intertherm M7RL Series user manual

HDG

HDG Pelletmaster 15 Operation manual

Pinnacle

Pinnacle Aero Bella AB-716C-QH User's manual and operating instructions

Nortek

Nortek MG2S Series installation instructions

VERDER

VERDER CARBOLITE GERO ABF 8/28 Installation, operation and maintenance instructions

Goodman

Goodman GMV9 Installation & operating instructions

SUPREME

SUPREME SUP10-M2301C Installation instructions and homeowner's manual

Dettson

Dettson AMT400B34-SM1PMA Installation instructions and homeowner's manual

Evcon

Evcon DGD 60 MBH installation instructions

Trane

Trane S8B1A026M2PSAB Installer's guide

Hart Sceintific

Hart Sceintific 9113 user manual

Whirlpool

Whirlpool Gold WGGE45 installation instructions