7

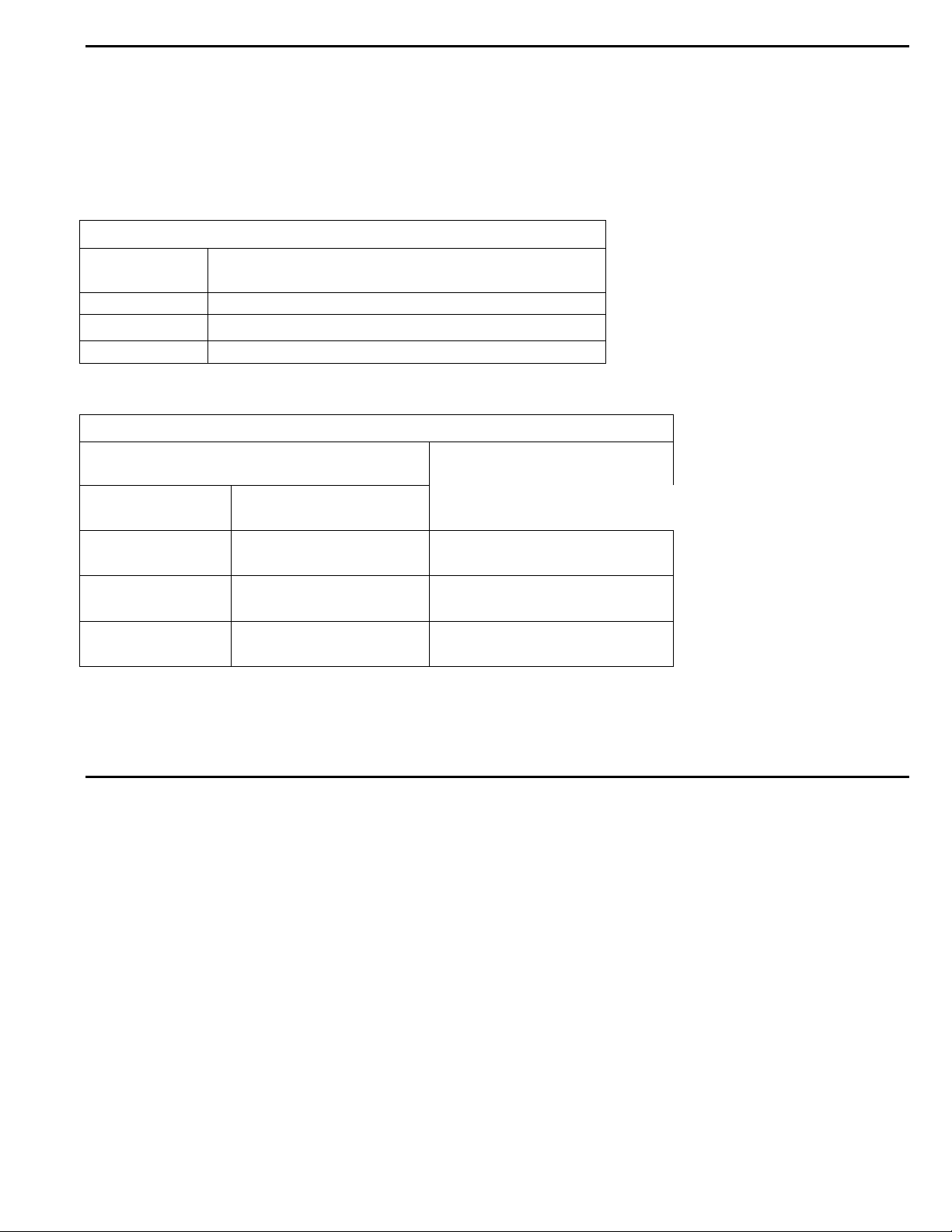

Average temperature of hot tap water..............................................................140.0° F

Average temperature of hot coffee....................................................................180.0° F

Normal operating temperature of a fully loaded electric

motor open type, 70° F ambient temperature ...................................................174.0° F

1. Be sure sheaves are locked in position.

2. Key should be seated firmly in keyway.

3. Place straight edge or taut cord across faces of. driving and driven sheaves to check alignment. The V-belt

drive assembly can be mounted as follows: motor and fan shafts must be parallel with V-belts and at right

angles to the shafts.

4. Start the fan. Check for proper rotation. Run fan at full coat with heavy oil for ease of shaft entry.

Remove oil, speed. A slight bow should appear on slack side of grease, rust or burrs from sheave grooves.

belt. Disconnect power and adjust belt tension by sheave on adjusting motor on its sliding base. All belts

must have some slack on one side.

5. If belts squeal at start up, they may be too loose.

6. When belts have had time to seat in the sheave grooves, then readjust belt tension.

V-belt drive assembly can be mounted as follows:

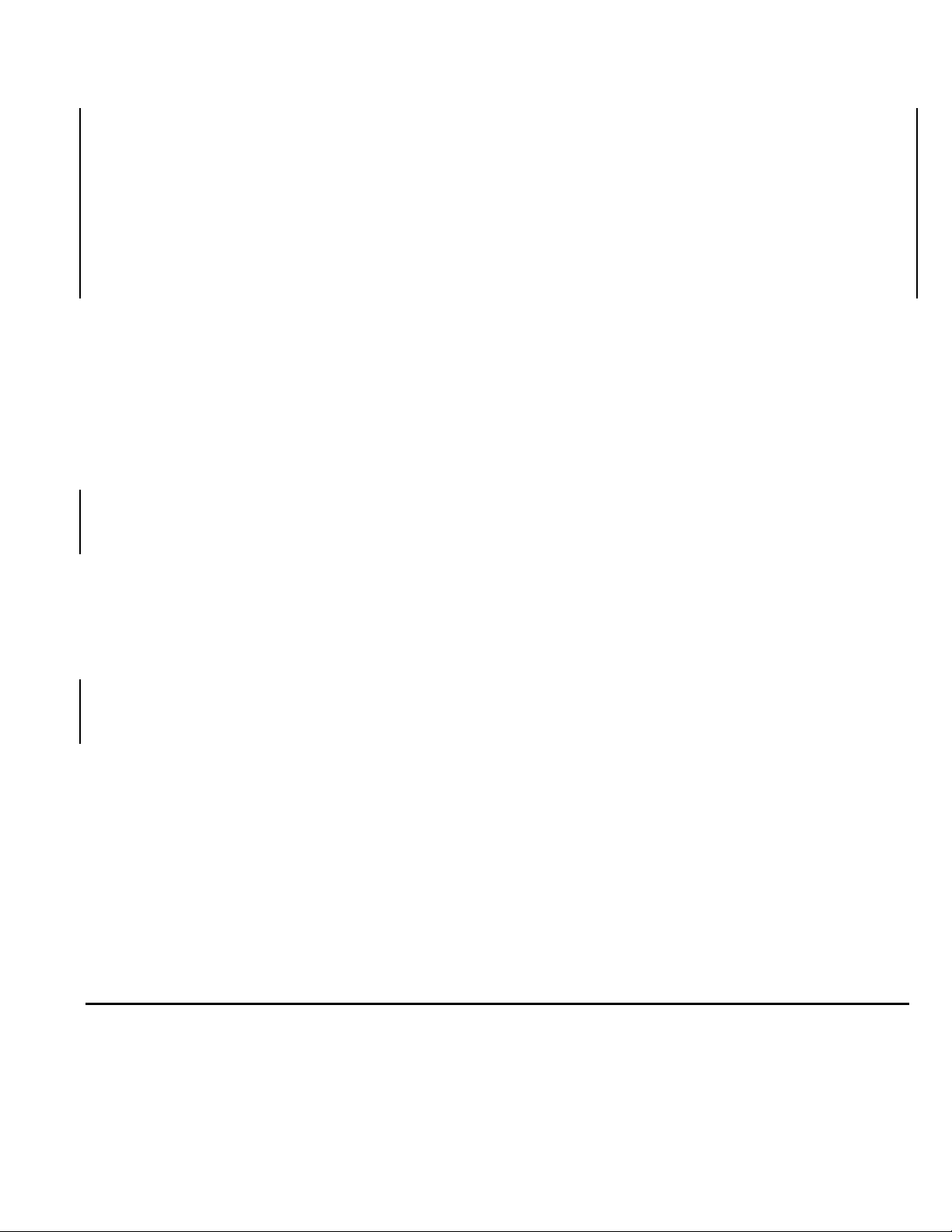

1. Clean motor and fan shafts. Be sure they are free from corrosive material. Clean bore of sheaves and

coat with heavy oil for ease of shaft entry. Remove oil, grease, rust or burrs from sheave grooves.

2. Place fan sheave on fan shaft and motor sheave on its shaft. Do not pound sheaves on as this may

damage bearings. Tighten sheaves per Table #1 or #2.

3. Move motor on slide base so belts can be placed in grooves of both sheaves without forcing. Do not roll

belts or use a tool to force belts over the grooves.

4. Align fan and motor shafts so they are parallel. The belts should be at right angles to the shafts. A straight

edge or taut cord placed across the face of the sheaves will aid in alignment.

5. Tighten belts by adjusting motor base. Correct tension gives the best drive efficiency. Excessive tension

causes undue bearing pressure.

6. Start the fan and run it at full speed. Adjust belt tension until only a slight bow appears on the slack side of

the belts. If slippage occurs, a squeal will be heard at start-up. Eliminate this squeal by disconnecting or

locking out motor from power source and then tightening up the belts.

7. Give belts a few days running time to become seated in sheave grooves, then readjust belt tension. If the

shafts become scratched or marked, carefully remove sharp edges and high spots such as burrs with

fine emery cloth or honing stone. Avoid getting emery dust in the bearings. Do not apply any belt dressing

unless it is recommended by the drive manufacturer. V-belts are designed for frictional contact between the

grooves and sides of the belts. Dressing will reduce this friction. Belt tension on an adjustable pitch drive is

obtained by moving the motor, not by changing the pitch diameter of the adjustable sheave.

BEARING MAINTENANCE

Sealed Bearings

Sealed for life bearings are pre-lubricated with the correct amount of manufacturer approved ball

bearing grease, and are designed for application where relubrication is not required.

Relubricatable Bearings

The motor bearings and fan bearings on belt drive fans should be greased at regular intervals. Motor

manufacturers greasing instructions and recommendations should be followed closely. Avoid the use of a

pressure greasing system which tends to fill the bearing chamber completely. Do not over grease.

NOTE: On motors with non-regreasable, sealed bearings, no lubrication is required for the life of the

bearing.

Table #3 lists the time intervals between fan greasing to insure proper lubrication in adverse conditions of