3-6

adjust CTL waveform to the following procedures.

A. If is over 2.5 :1, lower the head height.

After turning the height adjust screw counter-clockwise to

adjust its level from 1.5 : 1 to 2 : 1.

Check the tape location at P4. Readjust the TILT.(2:1)

B. If is under 1.5:1, heighten the head height.

After turning the height, adjust the screw clockwise to

adjust its level from 2 : 1 to 2.5 : 1.

Check the tape location of P4. Readjust the TILT.(2:1)

3. Play the standard tape and adjust very carefully the azimuth

screw right and left by using the oscilloscope and level-

meter to maximize the audio sound.

Adjust the azimuth screw & the height adjust screw at the

same time because they have mutual relationship. (Check

CTL again after the adjustment)

*A/C head adjustment order

Height adjust screw->check the TILT->azimuth screw

->check CTL

3.2.3 AUDIO LEVEL CHECKING AND ADJUSTMENT

1. Connect “+” terminal of RMS meter (auto level meter) to J108

on the main PCB Audio output and “-” terminal to GND.

2. Check that if audio level of RMS meter satisfies with the

spec,If audio sound is weak, adjust the A/C head azimuth

screw.

3. Audio level spec

1K :0.5 !0.1Vrms

6K :1KHz !1.5dB

3.3. X-DISTANT/P2,P3 ADJUSTMENT

3.3.1. NECESSARY INSTRUMENT

1. SP PAL TAPE

2. OSCILLOSCOPE

3. 10:1 PROBE : 2 PIECES

4.SPEACIAL DRIVER FOR ADJUSTMENT(P2,P3,X-

DISTANT(NUT),AUDIO(NUT))

5. RMS METER(AUDIO LEVEL METER)

3.3.2. ADJUSTMENT PREPARATION

1.Connect oscilloscope(CH-1) to J123(H/SW) on main PCB.

(Use for trigger of CH-2 )

2.Connect oscilloscope(CH-2) to J158(RF) on main PCB.

(Use waveform of CH-2)

3. Play by inserting SP PAL TAPE. (2hd:normal tape)

4. After the picture is appeared, make initial condition by

pressing the tracking adjustment up(+) button of the remote

controller.

3.3.3. X-DISTANCE ADJUSTMENT

1. Turn the X-distant adjust groove of the deck right and left to

maximize the scope waveform.

2. Check that if waveform satisfies with the linearity by pressing

TRK Up(+) and Down(-) button.

3. Tighten the X-distant adjust screw.

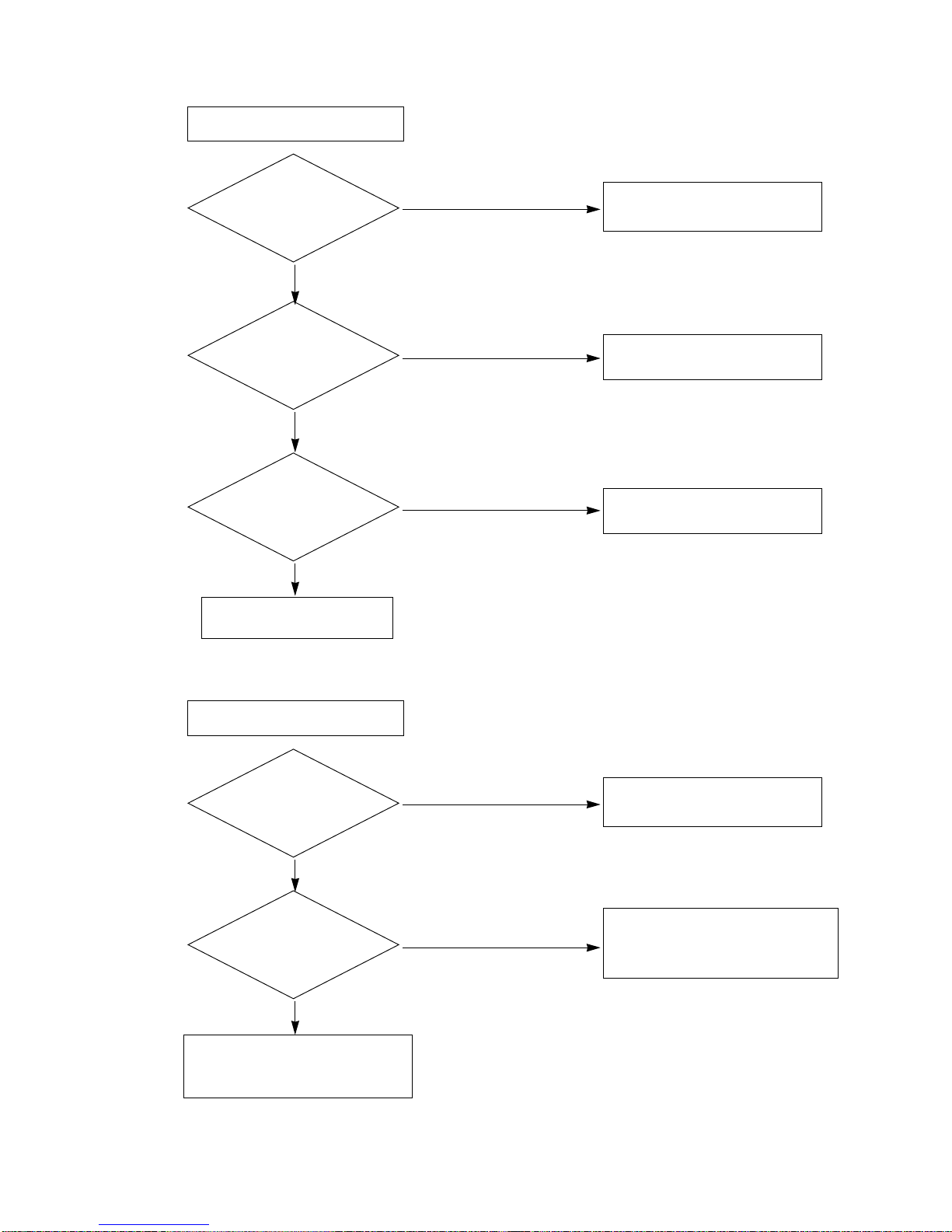

3.3.4. P2/P3(RF LINEARITY) CHECK & ADJUSTMENT

1. Adjust p2 & p3 so that the the RF envelope waveform of the

oscilloscope becomes C in figure 2.

2. Check if the envelope waveform becomes maximum by

pressing TRK Up(+),Down(-) button onestep.

3.4. PG ADJUSTMENT

Adjust it after finishing controlling the Deck.

3.4.1.NECESSARY INSTRUMENT

1. SP PAL TAPE

2. OSCILLOSCOPE

3. 10 : 1 PROBE : 2 PIECES

3.4.2. ADJUSTMENT

1. Insert and play the SP PAL TAPE.

2. Connect the oscilloscope(CH-1) to H/SW(J123) on the main

PCB and trigger in setting the VOL/DIV to 1V range.

3. Connect the oscilloscope(CH-2) to video out(J173) on the

main PCB and set the VOL/DIV to 500mV range.

4. Set the TIME/DIV of oscilloscope to 50us range.

5. Adjust the falling edge(412us !20us) of vertical sync in the

video signal by varying VR01.

4.ASSEMBLY LINE ADJUSTMENT

4.1. RF AGC ADJ.( APPLYING THE W/S TUNER )

4.1.1. NECESSARY INSTRUMENT : DIGITAL MULTIMETER

4.1.2. ADJUSTMENT PREPARATION

1. HEAT-RUN at least 15 minutes before adjustment.

2. Input the PAL DIGITAL PATTERN(EU05); The intensity of

electric field for the applied tuner refers to the below data.

3. Connect the DIGITAL MULTIMETER to TP-AGC(J335) of

MAIN1.

4.1.3. ADJUSTMENT

1. Press the SVC key of the transmitter and select¡AGC¡–of the

SVC MENU using PR+/- key.

2. Adjust it by the below data varying VOL+/- key.

4.2. FOCUS ADJUSTMENT

4.2.1. Receive the standard color signal.

4.2.2. Let the picture be the most clear by the criterion of the

vertical line of it, varying the focus V/R of FBT.