- 10 -

11. Adjustment of hite Balance

11-1. Requirement

VBef re adjusting White-balance , the AV ADC sh uld be

d ne.

11-2. Required Equipment

1) Rem te c ntr ller f r adjustment.

2) C l r Analyzer.( CA-1000,CA-100+,CA-200 r same

pr duct ) : CH10(PDP)

* Please adjust CA-210, CA-100+ by CS-1000 before

measuring.

3) Aut W/B adjustment instrument.( nly f r Aut adjustment)

4) AV Pattern Generat r.

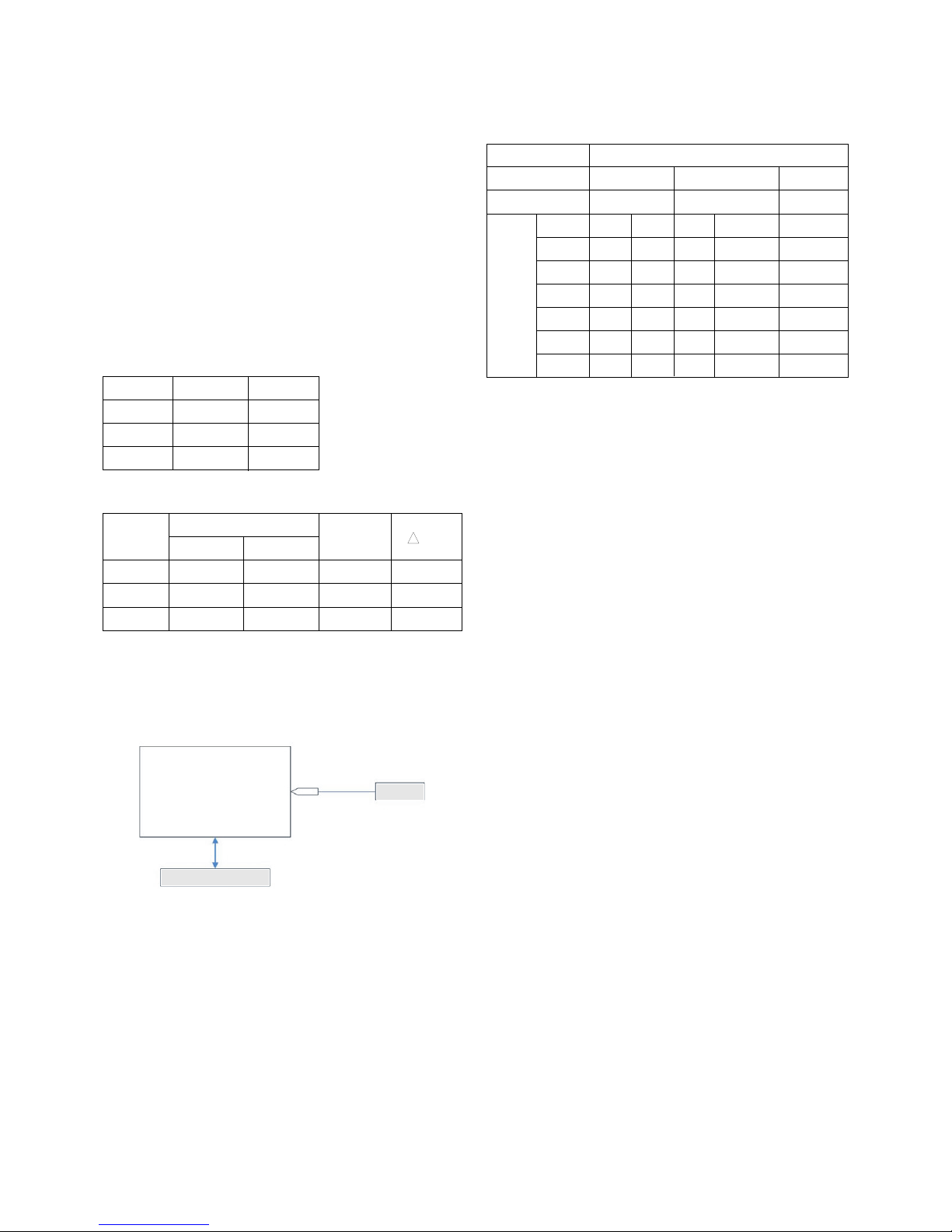

W Synchr nizati n relati n between PSM and CSM.

W

CS-1000/CA-100+/CA-210 White balance adjustment c rdinate

and c l r temperature.

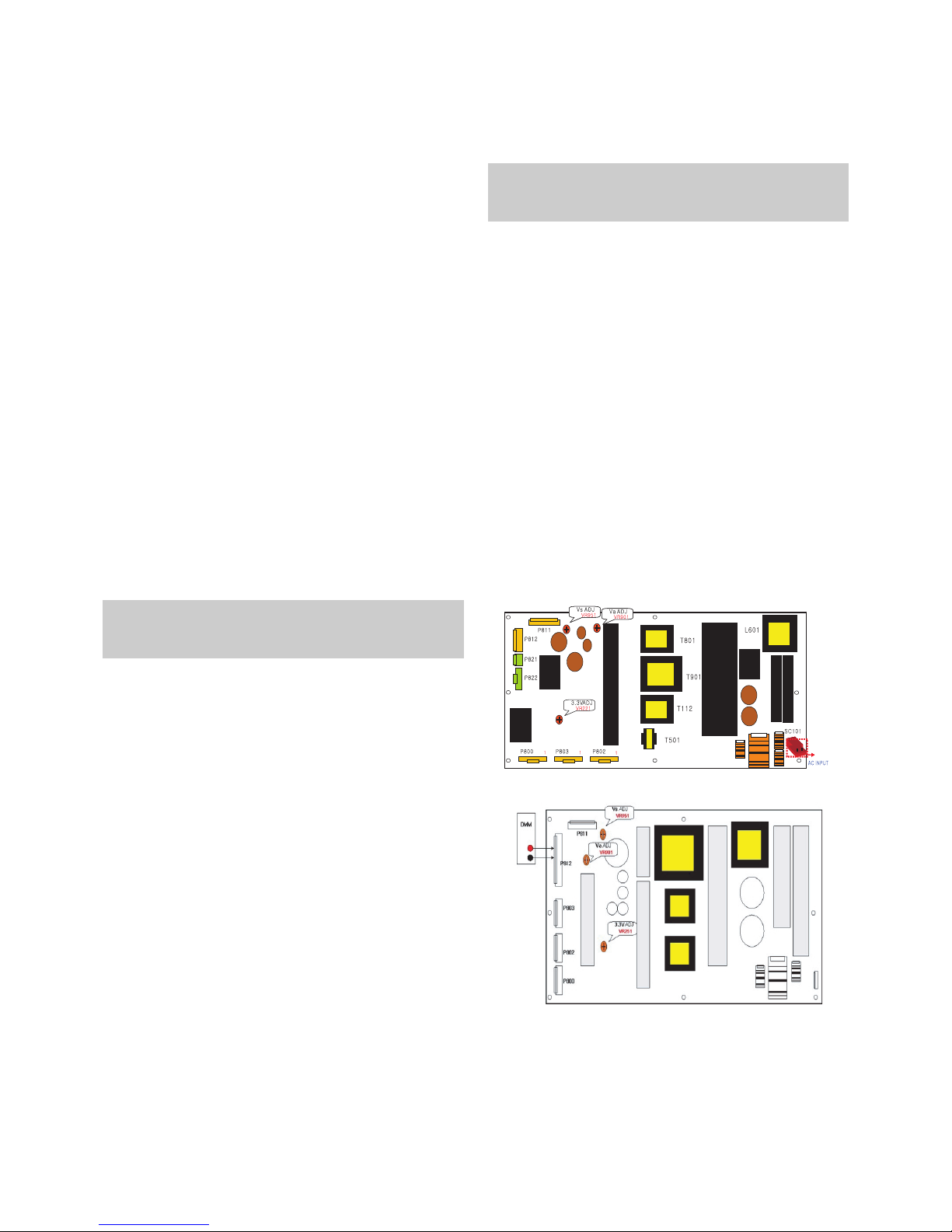

11-3. Connection Picture of the Measuring

Instrument(On Automatic control)

V Inside PATTERN is used when W/B is c ntr lled. C nnect

t aut c ntr ller r push c ntr l R/C IN-START -> Enter

the m de f White-Balance, the pattern will c me ut.

V Aut -c ntr l interface and directi ns

1. Adjust in the place where the influx f light like fl dlight

ar und is bl cked.(illuminati n is less than 10ux)

2. Measure and adjust after sticking the C l r Analyzer(CA-

100+, CA210) t the side f the m dule.

3. Aging time : keep white pattern using inside pattern.

WAut adjustment Map(RS-232C)

12. Adjustment of hite Balance

(Manual white Balance)

V One f R Gain/ G Gain/ B Gain sh uld be kept n 80, and

thers are c ntr lled l wering fr m 80

(1) ‘p wer n’ f the c ntr l R/C, set heat run t white by

pressing and heat run ver 15 minutes. (Set: RS-232 H st:

PC, Baud Rate: 115200bps, D wnl ad: C rtez)

(2) Zer Calibrate CA-100+, and stick the sens r t the center

f PDP m dule surface when y u adjust.

(3) D uble click In-start key n C ntr lling R/C and get in

‘white balance’.

(4) Set test-pattern n and display inside pattern. C ntr l is

carried ut n three c l r temperature, COOL, MEDIUM,

WARM. (C ntr l is carried ut three times.)

(5) When the R/G/B GAIN is 80 n OSD, it is the FULL

DYNAMIC Range f the M dule. In rder t c ntr l white

balance with ut the saturati n f FULL DYNAMIC Range

and DATA, ne f R Gain / G Gain / B Gain sh uld be kept

n 80, and ther tw is c ntr lled l wering fr m 80.

* C l r Temperature: C l, Medium, Warm

(1) When R GAIN is set t 80

- C ntr l G GAIN and B GAIN by l wering fr m 80.

(2) When B GAIN is set t 80

- C ntr l R GAIN and G GAIN by l wering fr m 80.

(3) When G GAIN is set t 80

- C ntr l R GAIN and B GAIN by l wering fr m 80.

One f R Gain / G Gain / B Gain sh uld be kept n 80, and

adjust ther tw l wer than 80.

(When R/G/B GAIN are all 80, it is the FULL DYNAMIC

Range f M dule)

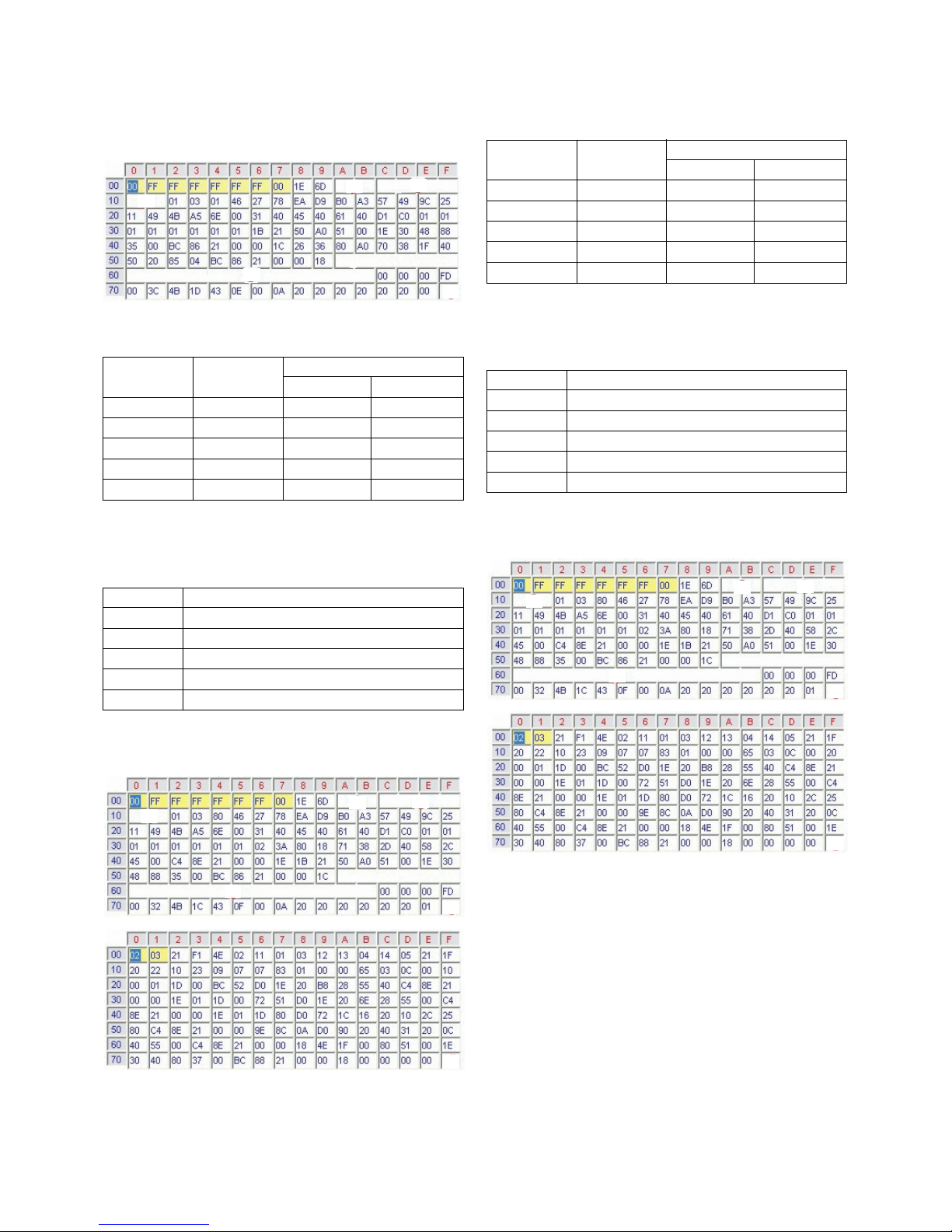

(Fig. 6) Aut AV(CVBS) C l r Balance Test Pattern