2

IMPORTANT SAFETY NOTICE!

This service information is intended for individuals possessing adequate backgrounds of

electrical, electronic, and mechanical experience. Any attempt to repair this appliance may result

in personal injury or property damage. The manufacturer or seller can not be responsible for the

interpretation of this information, nor can it assume any liability in connection with its use.

WARNING: To reduce the risk of fire, electric shock, or personal injury when using this

appliance, follow basic precautions, including the following:

Wear gloves when working.

Failure to do this can result in serious injury.

The appliance is heavy. Two or more people is

required when moving the appliance.

There is a risk of serious back injury or other injuries.

Certain internal parts are intentionally not

grounded and may present a risk of electric

shock only during servicing. Service personnel -

Do not contact the following parts while the

appliance is energized: Pump bracket, rotor, and

heater.

To reduce the risk of fire, electric shock, or personal injury when using this appliance, follow basic precautions,

including the following.

Disconnect this appliance from the power

supply before servicing. Turning the controls to

the off position does not disconnect this

appliance from the power supply.

Failure to do this can result in shock.

Reconnect all grounded devices after servicing.

Failure to do this can result in shock.

CONTENTS

1. SPECIFICATIONS...................................................................................................................... 3

2. FEATURES AND BENEFITS...................................................................................................... 4

3. HOW TO USE ............................................................................................................................ 5

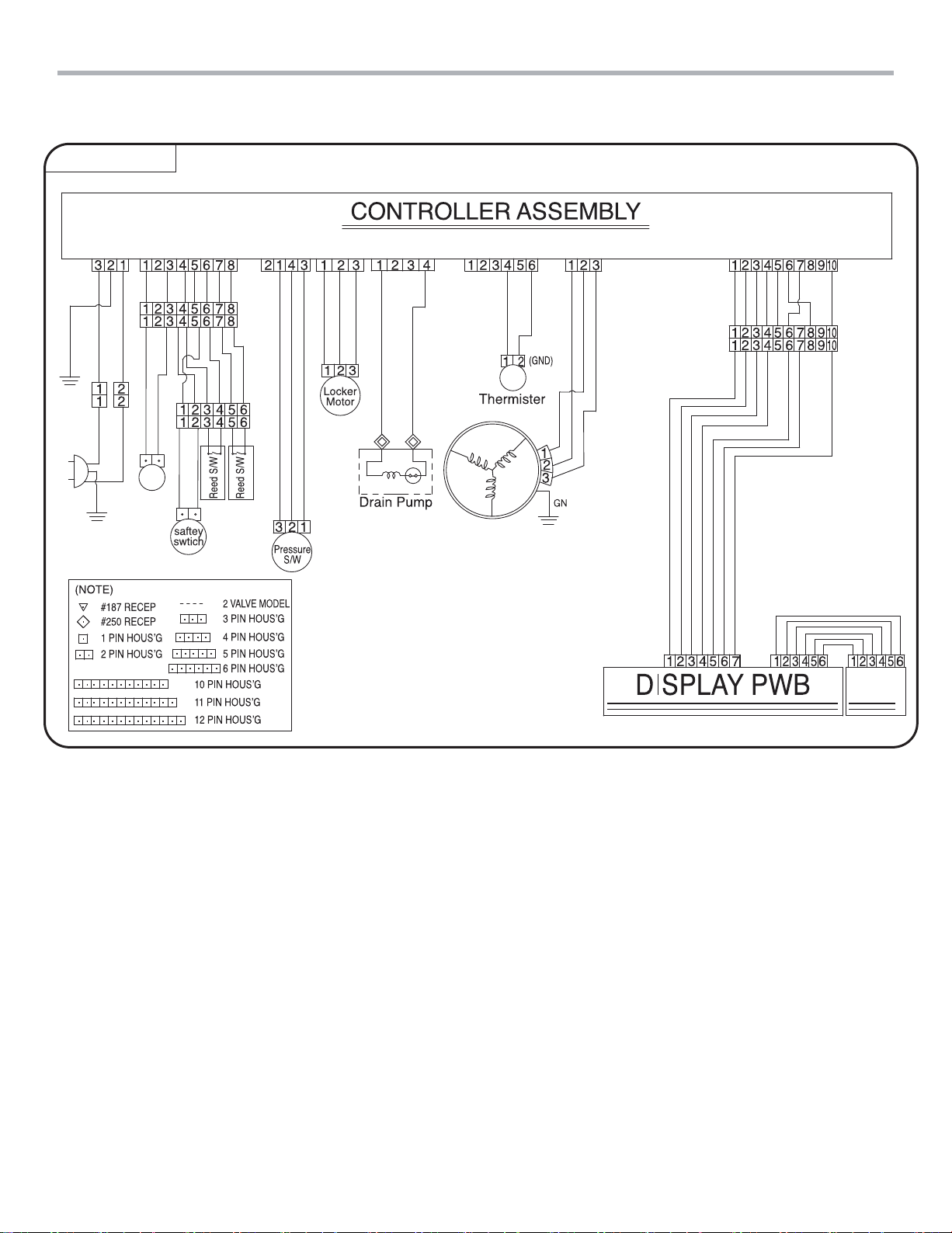

4. WIRING DIAGRAM .................................................................................................................... 6

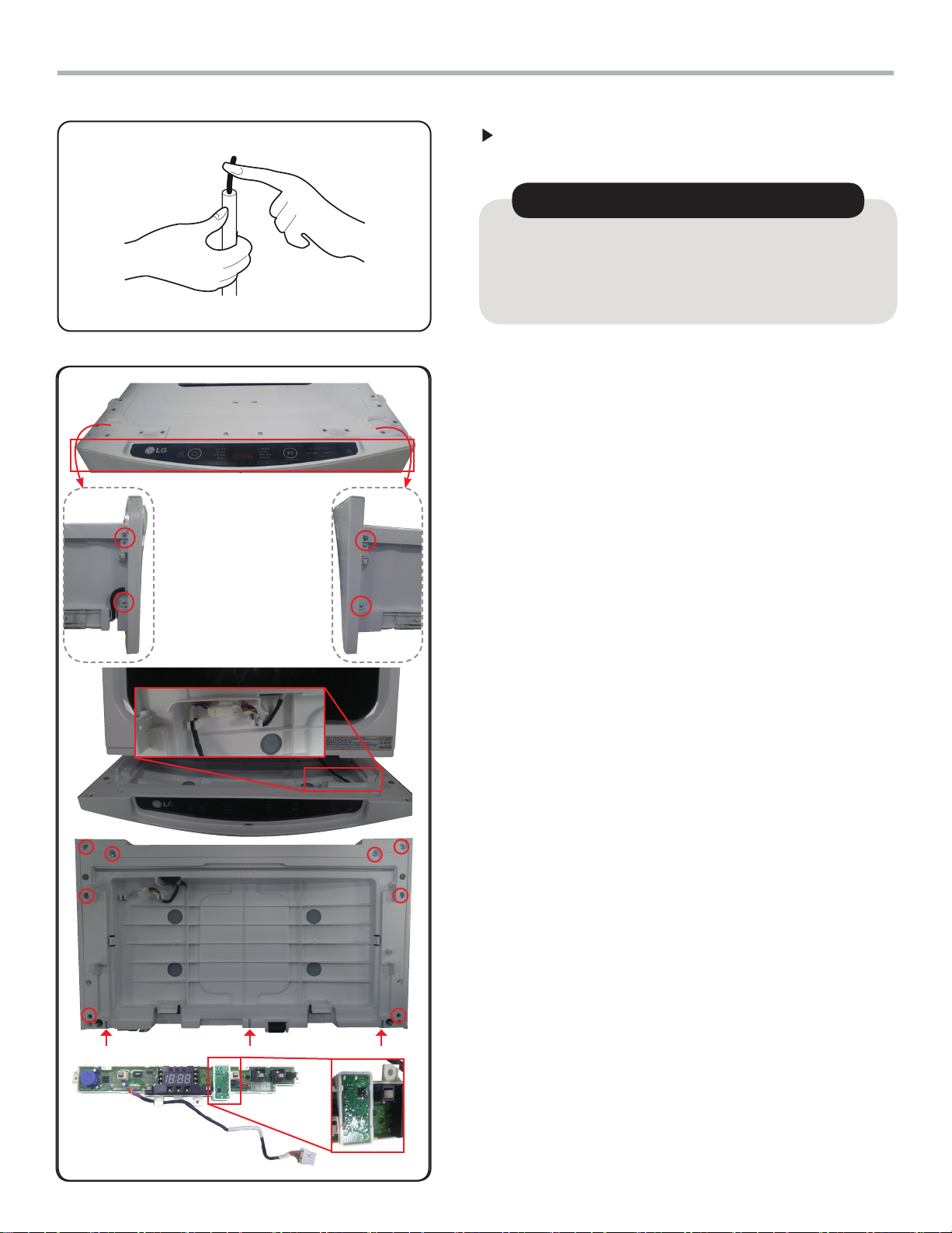

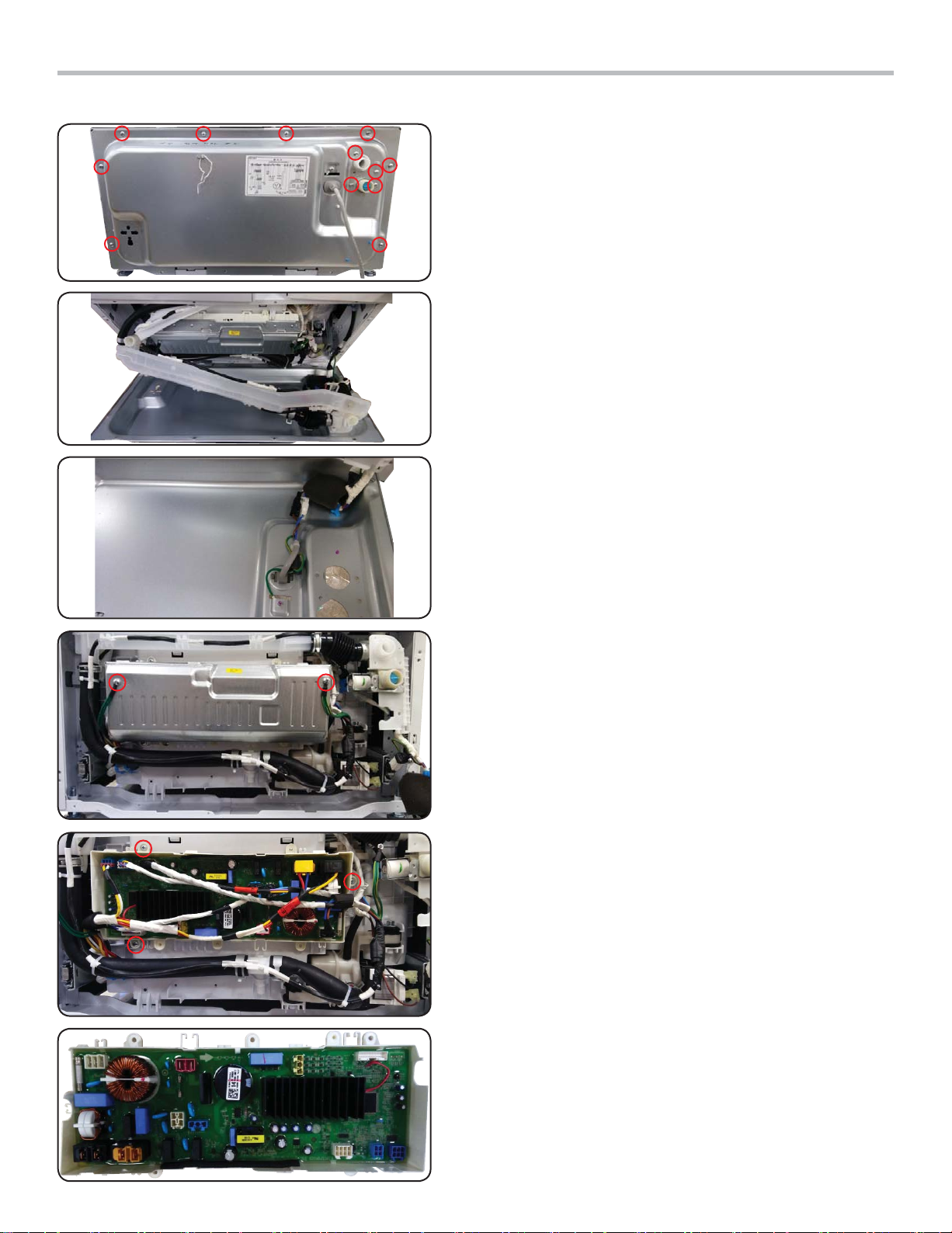

5. MAIN PCB PICTURE ................................................................................................................. 7

6. SERVICE INFORMATION ......................................................................................................... 8

7. HOW TO USE SVC TEST MODE .............................................................................................19

8. ERROR CODES......................................................................................................................... 20

9. EXPLODED VIEW........................................................................................................................... 22

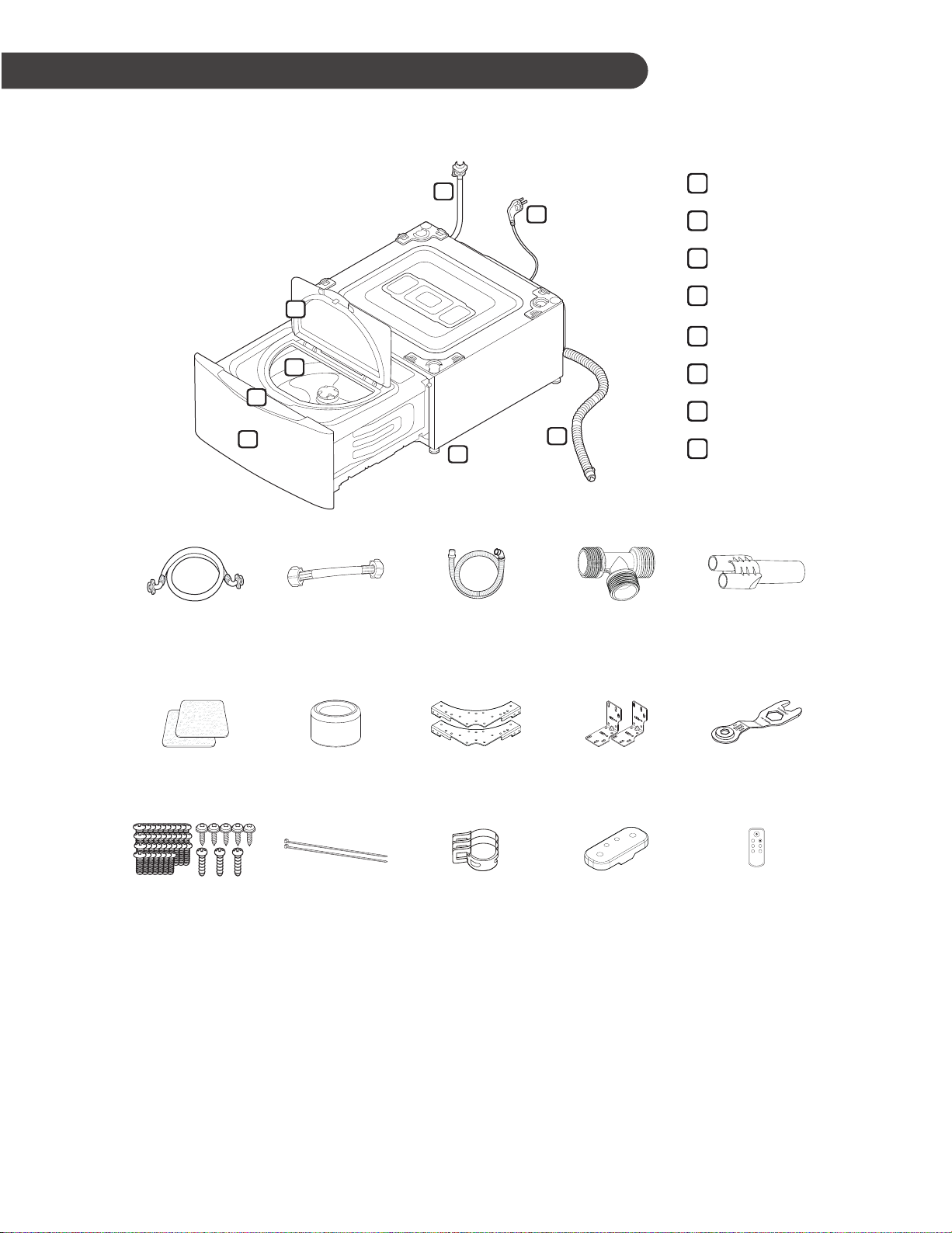

9-1. EXPLODED VIEW OF OUTER CASE ASSEMBLY .......................................................... 22

9-2. EXPLODED VIEW OF FRONT COVER ASSEMBLY ....................................................... 23

9-3. EXPLODED VIEW OF DRAWER ASSEMBLY ................................................................. 24

9-4. EXPLODED VIEW OF TUB ASSEMBLY ......................................................................... 25

9-5. EXPLODED VIEW OF ACC. ASSEMBLY...........................................................................26

SAFETY PRECAUTION!